Circulating treatment system and method for etching solution

A processing system and etching technology, which is applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve the problems of poor electrolysis effect, many solid impurities, high impurity rate of copper, etc., and achieve low cost, environmental protection and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

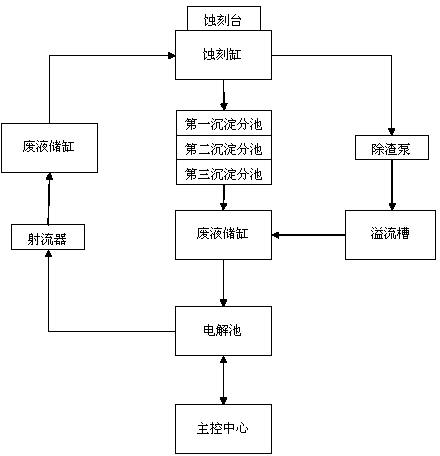

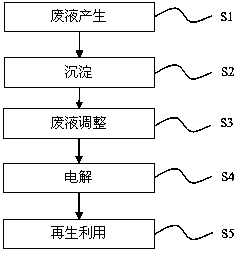

[0035] Such as figure 1 As shown, after the etching treatment of the etching solution, the generated waste liquid passes through the tertiary precipitation of the sedimentation tank, and the solid complex in the waste liquid is filtered out. After the waste liquid flows into the waste liquid storage tank, hydrochloric acid solution is added to adjust the pH of the waste liquid. The value is 3, the temperature of the waste liquid is 20°C, the concentration of copper ions is 20g / l, the waste liquid enters the electrolytic cell, and the current density of the cathode is 400 A / m during electrolysis 3 , the current density of the anode is 100A / m 3 , the flow rate of the electrolyte during electrolysis is 1 m 3 / h, such a cycle will precipitate metal copper on the cathode electrolytic plate, and the electrolysis efficiency will reach 95%. The solution after electrolysis will flow into the etching cylinder through the regeneration mixing pool for recycling.

Embodiment 2

[0037] Such as figure 1As shown, after the etching treatment of the etching solution, the generated waste liquid passes through the tertiary precipitation of the sedimentation tank, and the solid complex in the waste liquid is filtered out. After the waste liquid flows into the waste liquid storage tank, hydrochloric acid solution is added to adjust the pH of the waste liquid. The value is 4, the temperature of the waste liquid is 30°C, the concentration of copper ions is 27g / l, the waste liquid enters the electrolytic cell, and the current density of the cathode is 800 A / m during electrolysis 3 , the current density of the anode is 80A / m 3 , the flow rate of the electrolyte during electrolysis is 1.2 m 3 / h, such a cycle will precipitate metal copper on the cathode electrolytic plate, and the electrolysis efficiency will reach 97%. The solution after electrolysis will flow into the etching cylinder through the regeneration mixing pool for recycling.

Embodiment 3

[0039] Such as figure 1 As shown, after the etching treatment of the etching solution, the generated waste liquid passes through the tertiary precipitation of the sedimentation tank, and the solid complex in the waste liquid is filtered out. After the waste liquid flows into the waste liquid storage tank, hydrochloric acid solution is added to adjust the pH of the waste liquid. The value is 2, the temperature of the waste liquid is 35°C, the concentration of copper ions is 35g / l, the waste liquid enters the electrolytic cell, and the current density of the cathode is 1500 A / m during electrolysis 3 , the current density of the anode is 150A / m 3 , the flow rate of the electrolyte during electrolysis is 1.5 m 3 / h, such a cycle will precipitate metal copper on the cathode electrolytic plate, and the electrolysis efficiency will reach 98%. The solution after electrolysis will flow into the etching cylinder through the regeneration mixing pool for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com