Marine environment and dynamic load coupling test equipment system

A technology of marine environment and test equipment, applied in the field of state simulation test, can solve the problems of lack of understanding of long-term durability of engineering, failure to consider the actual service of engineering structures, and inability to establish quantitative relationship of long-term durability of actual engineering in rapid tests, etc. Achieve the effects of strong sealing and high loading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

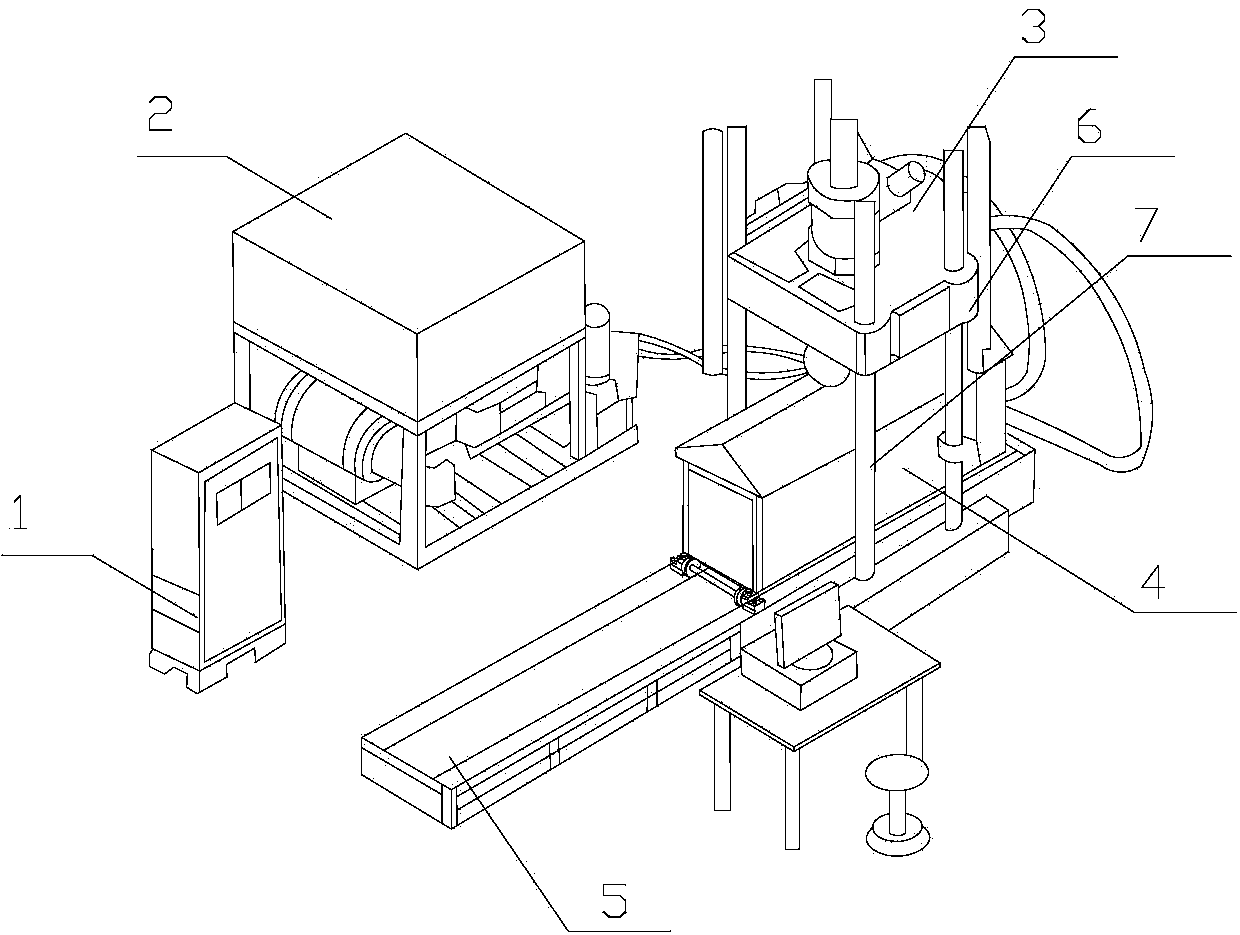

[0025] Such as figure 1 The marine environment and dynamic load coupling test equipment system shown includes marine environment simulation environment chamber equipment and electro-hydraulic servo dynamic and static testing machine.

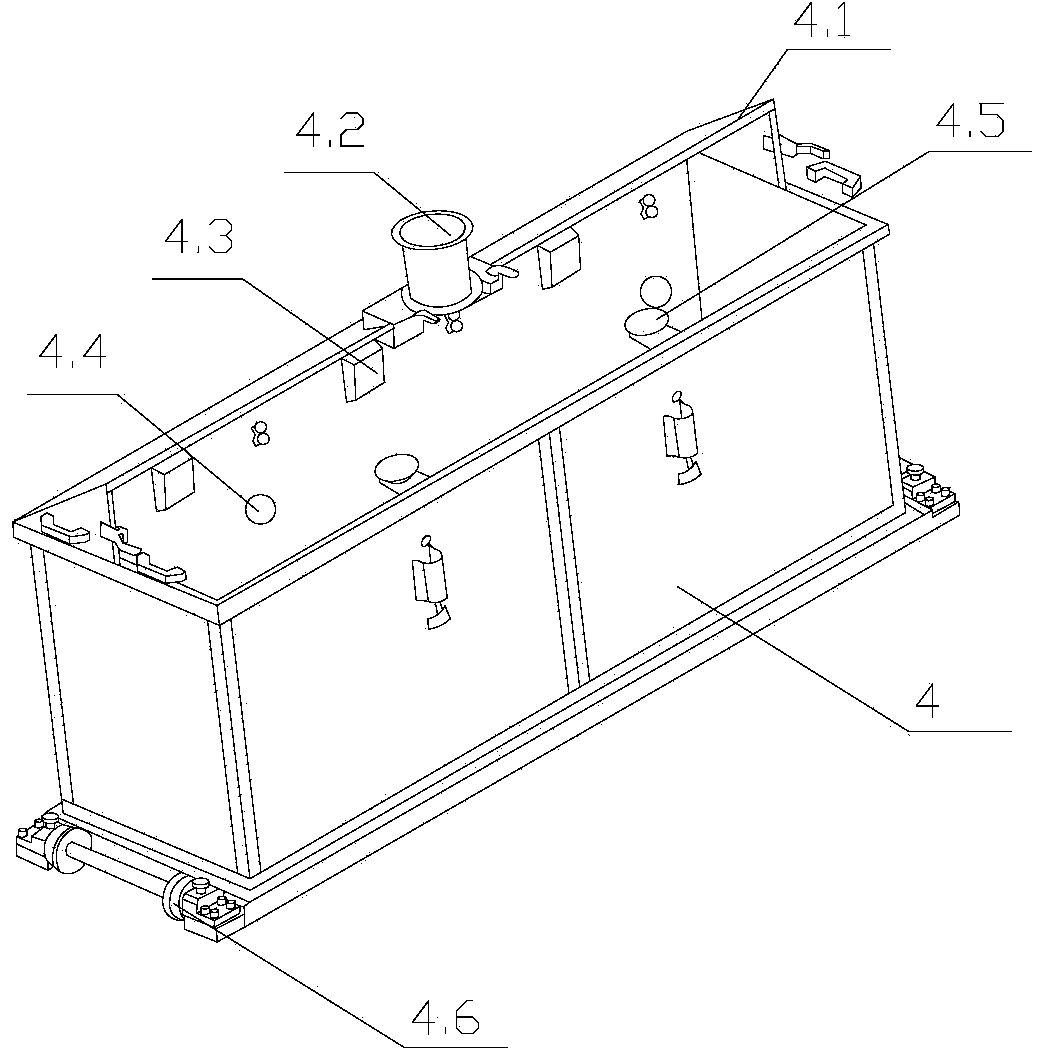

[0026] Described marine environment simulation environment box equipment comprises environment box 4 and salt water spraying device, as figure 2 As shown, the environmental box 4 is a roughly rectangular parallelepiped box in the form of a sealed box. The box body is made of stainless steel plate, supported by angle steel on all sides, and has an upper cover, which adopts the form of double-opening hinged door 4.1, that is, the upper cover is opened and closed by two hinged doors facing each other, and the opening or closing method is realized by an automatic gas spring; double-opening The opening of the hinged door is sealed with a telescopic cover 4.2, the frame of the double hinged door is sealed with a silicon rubber strip, and the doors o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com