Deep sub-micron device sample for in-situ transmission electron microscope and preparation method of sample

An electron microscope, deep submicron technology, applied in the preparation of test samples, etc., can solve problems such as limiting research efficiency and limiting nanoscale device research, and achieve the effect of improving experimental efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

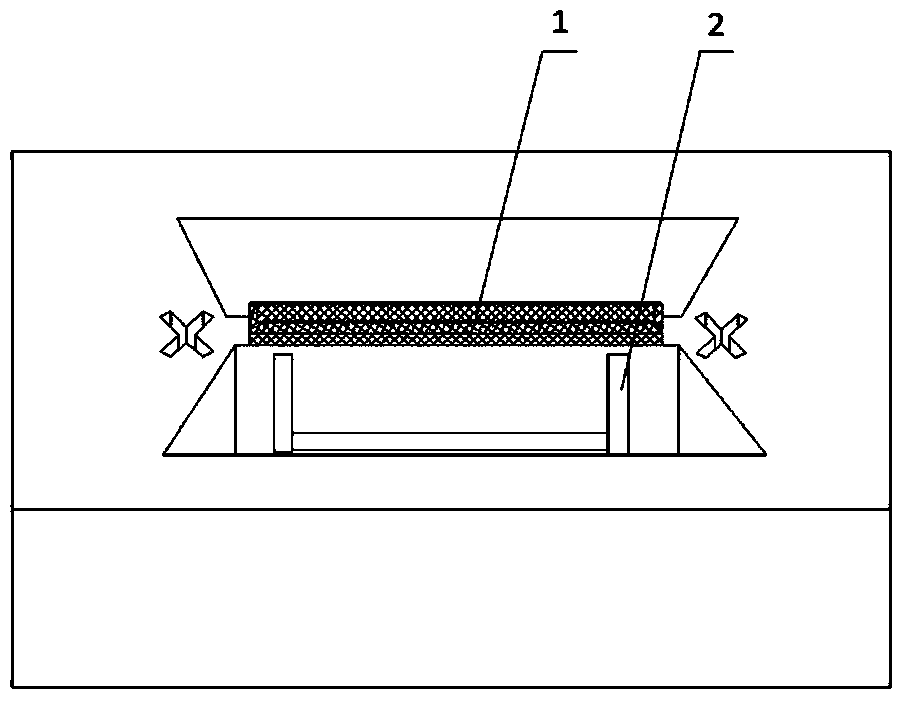

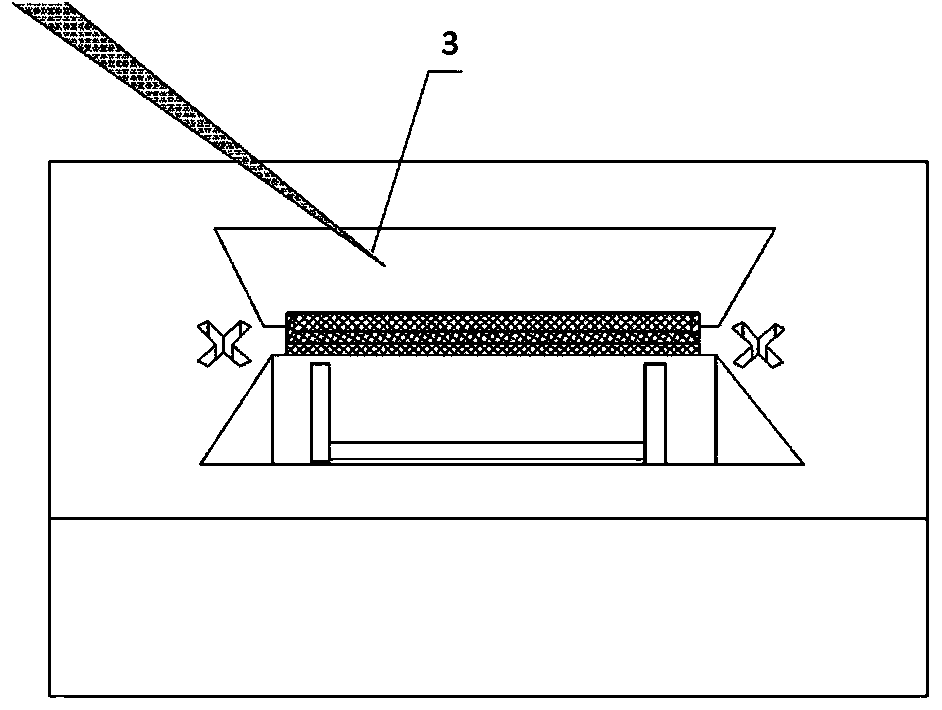

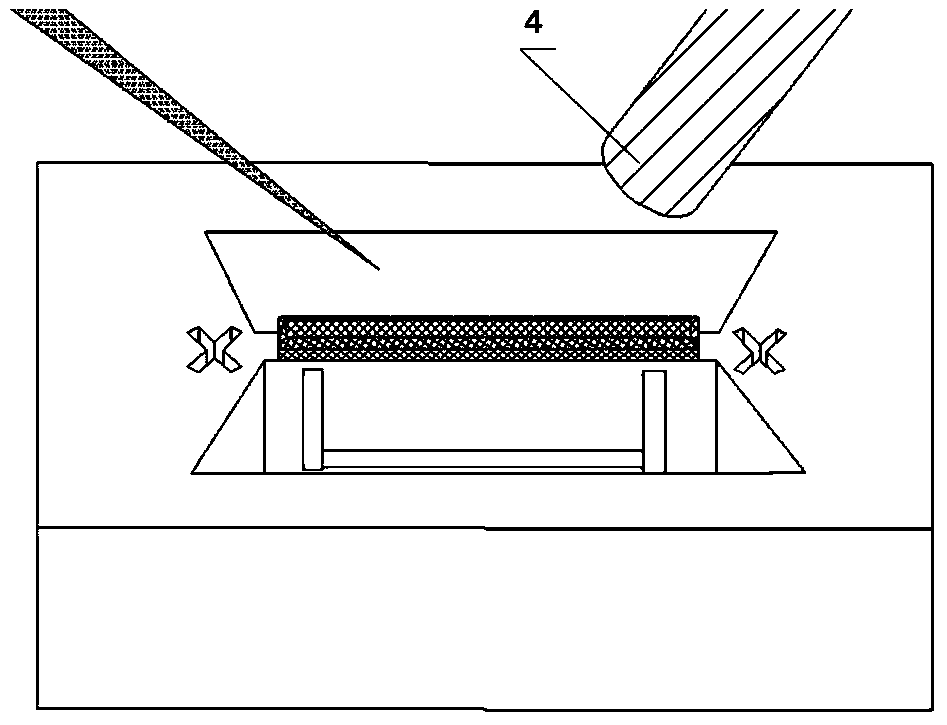

[0046] Figure 1-Figure 8 It is a schematic flow chart of an embodiment of a deep submicron device sample preparation method for in-situ transmission electron microscopy, where the labels are: platinum protective layer 1, "U"-shaped cut 2, mechanical manipulation arm 3, platinum ion gas source detector Needle 4, deposited platinum ions 5, preprocessed transmission electron microscope slice 6, special copper mesh for focused ion beam sample preparation 7, deposited platinum ions 8, containing multiple, discrete, regular shape, width less than 20 nanometers, thickness less than 100 nanometers In situ TEM samples of nanometers 9 .

[0047] Step 1: As shown in Figure (1), first deposit a platinum protective layer 1 with a thickness of ~1 micron on the area of interest of the bulk sample (the part where the TEM thin section sample is made), and use the sample stage to ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com