Photonic crystal power generating device based on lateral vibration band gap

A phononic crystal and power generation device technology, applied in the field of piezoelectric vibration power generation devices, can solve the problems of complicated cantilever beam design and high production cost, and achieve the effects of improving power generation efficiency, large power generation amount, and low design and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

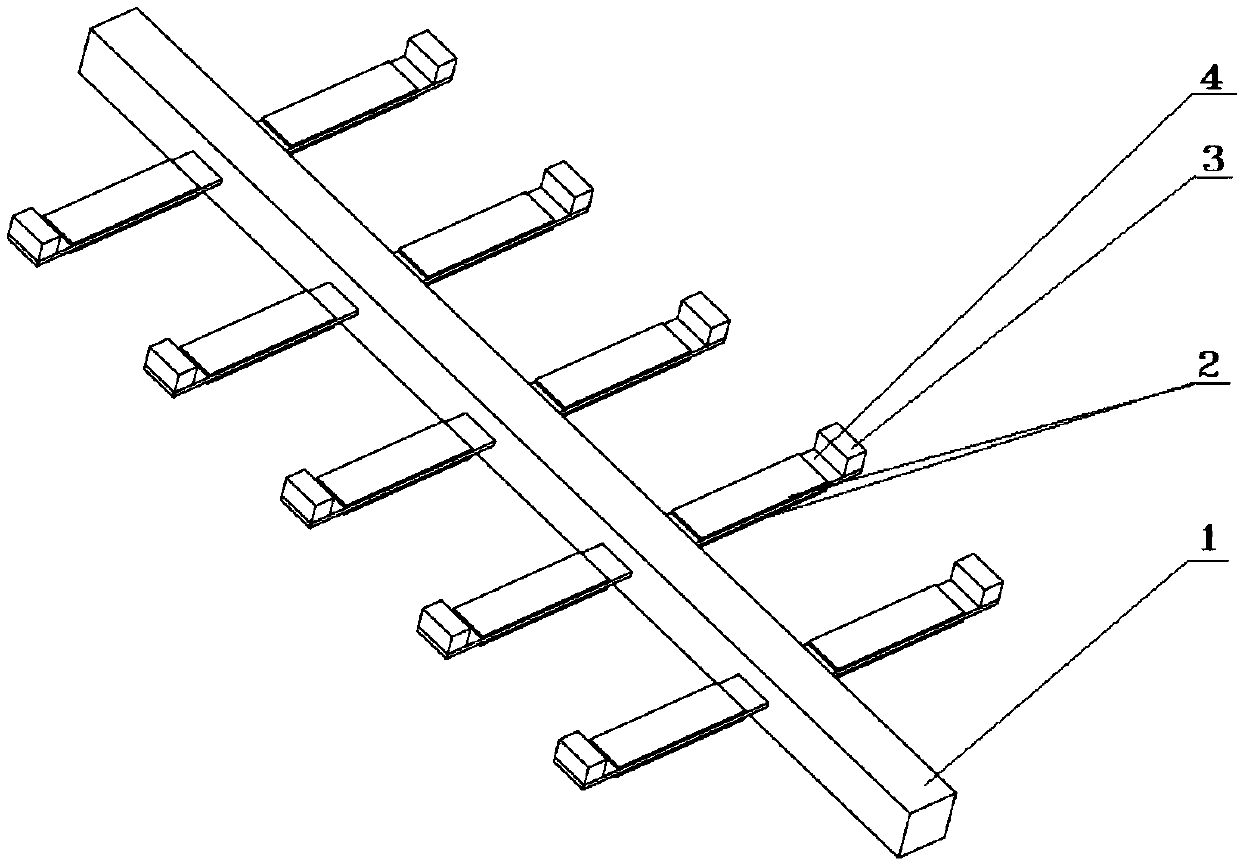

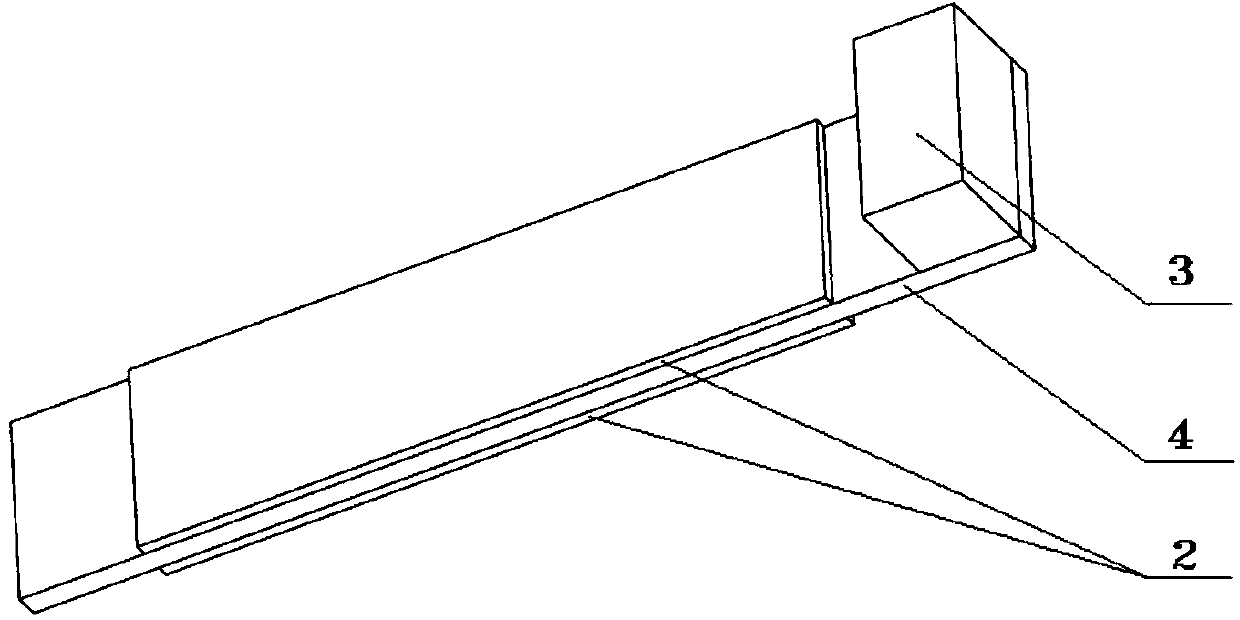

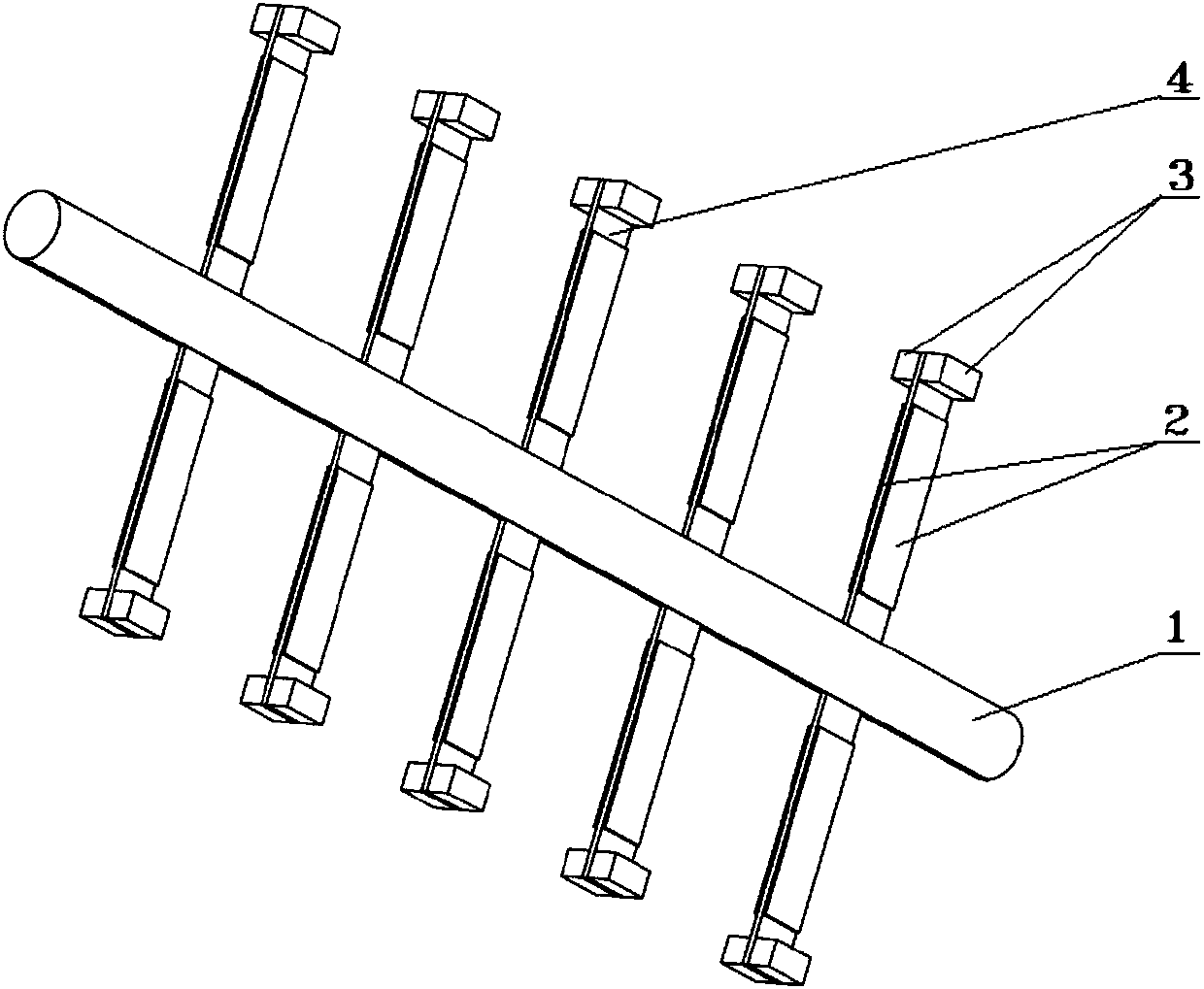

[0021] combine figure 1 , The technical solution of the present invention mainly includes a main beam 1, a piezoelectric material 2, a quality block 3 and a support beam 4.

[0022] The main beam 1 is used to connect with the machine base in the vibration environment or directly as the machine base, and the material is silicon, metal or elastic material, etc.; the material of the piezoelectric material 2 is piezoelectric ceramics or piezoelectric film; the material of the mass block 3 is copper , nickel and other metals; the material of the beam 4 is silicon. The piezoelectric material 2 and the mass block 3 are bonded to the support beam 4 by bonding and other reasonable processes to form a local vibrator. The local vibrator is installed on the main beam 1 symmetrically and equidistantly as a unit by welding, embedded connection, etc. , thus for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap