Composition containing soy protein hydrolyzate

A technology of soybean protein and composition, which is applied in the direction of drug combination, peptide/protein composition, medical preparations containing active ingredients, etc., can solve the problems of reducing the proliferation ability of keratinocytes, poor skin health status, and deterioration of metabolism, etc., to achieve Prevention/improvement of sagging or wrinkles, improvement of decreased metabolism, improvement of wrinkles and sagging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

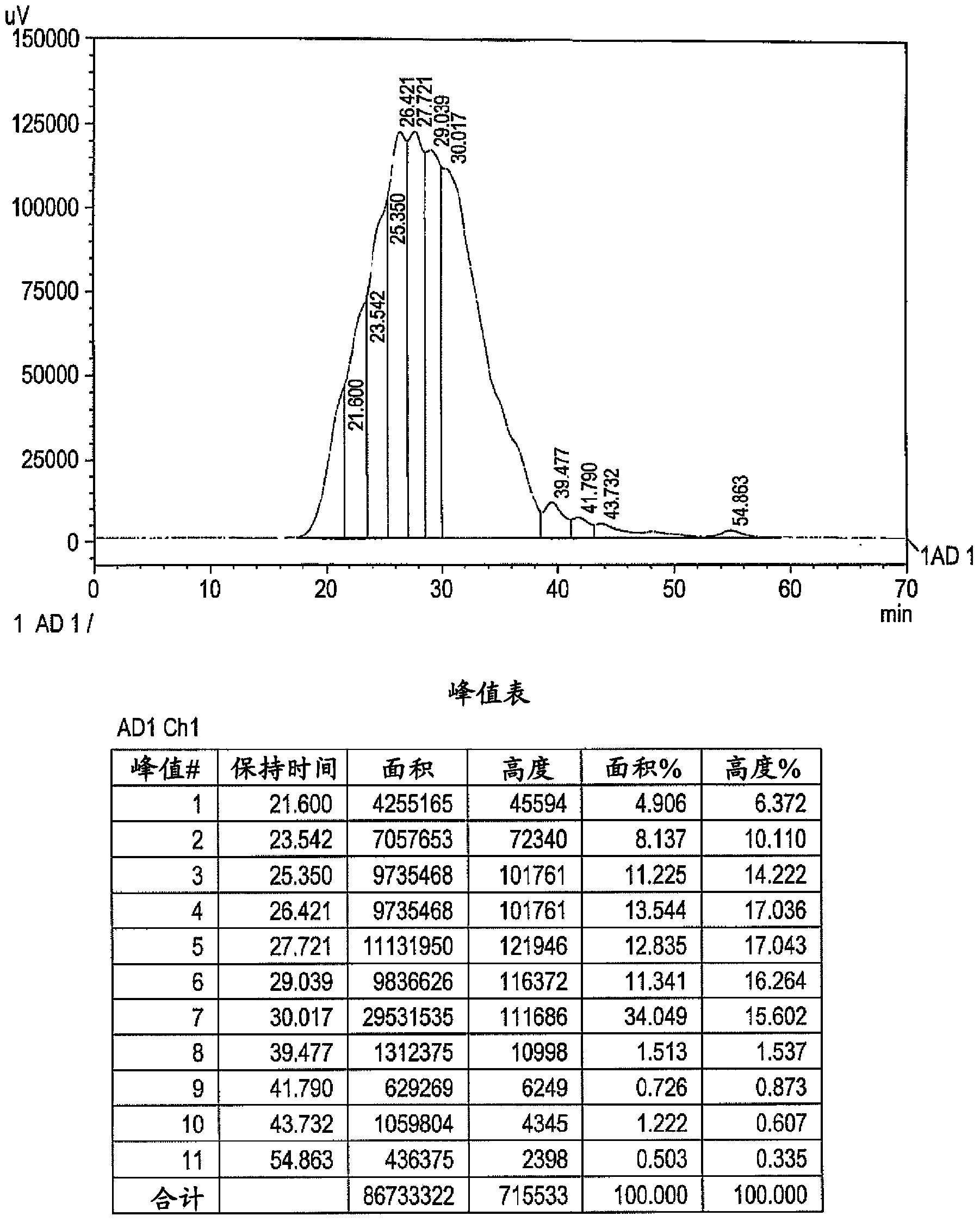

[0074] Example 1: Preparation of hydrolyzate of soybean protein (1)

[0075] Soybean protein was suspended so that the concentration of defatted soybean powder (trade name PROPHAM974, manufactured by ADM FAR EAST Co., Ltd.) was 5% (w / v), and added so that it became 0.05% (w / v) Pepsibio 1:10,000 (manufactured by Japan Biocon Co., Ltd.), which is a kind of pepsin, was decomposed at 50° C. for 18 hours. The pH of the reaction solution was implemented at pH 3.5 which is near the optimum pH of the protease.

[0076] After completion of the reaction, the above-mentioned reactant was heat-treated at 85°C for 15 minutes to inactivate the enzyme contained in the reactant, and then neutralized with 10N sodium hydroxide. Next, diatomaceous earth (Fuso Chemical, RADIOLITE #200) was precoated on the Buchner funnel, and suction filtration was performed. Next, the filtrate was concentrated under reduced pressure and freeze-dried to obtain powdered soybean protein hydrolyzate in a yield of ...

Embodiment 2

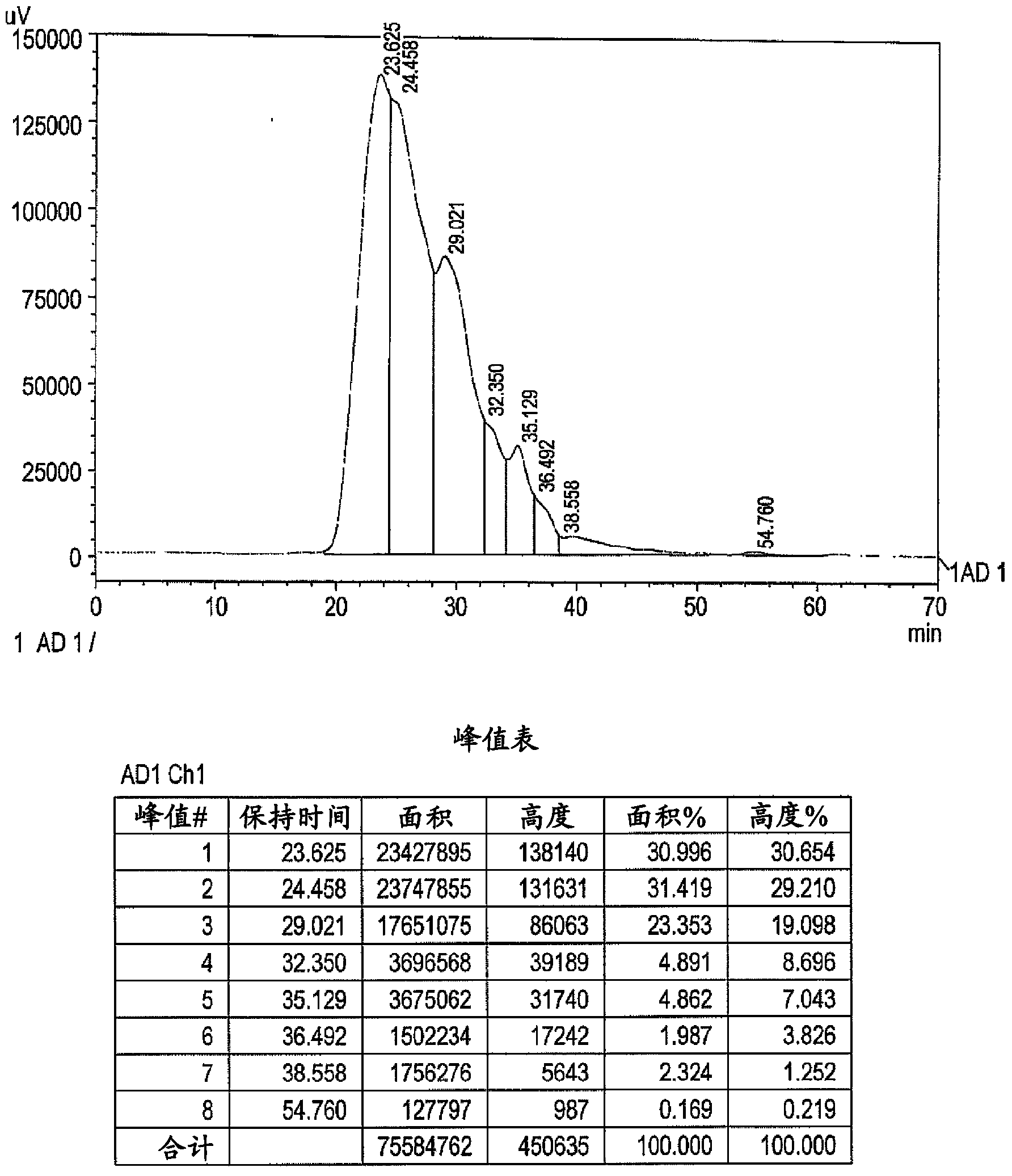

[0077] Example 2: Preparation of hydrolyzate of soybean protein (2)

[0078]Soybean protein was suspended so that defatted soybean powder (trade name PROPHAM974, manufactured by ADM FAR EAST Co., Ltd.) had a concentration of 5% (w / v), and pancreatic For protease, the decomposition reaction was carried out at 50°C for 18 hours. The pH of the reaction solution was implemented at pH 7.5, which is near the optimum pH of the protease.

[0079] After completion of the reaction, the above-mentioned reactant was heat-treated at 85° C. for 15 minutes to inactivate the enzyme contained in the reactant. Next, diatomaceous earth (Fuso Chemical, RADIOLITE #200) was precoated on the Buchner funnel, and suction filtration was performed. Next, the filtrate was concentrated under reduced pressure and freeze-dried to obtain powdered soybean protein hydrolyzate in a yield of 33.8%.

Embodiment 3

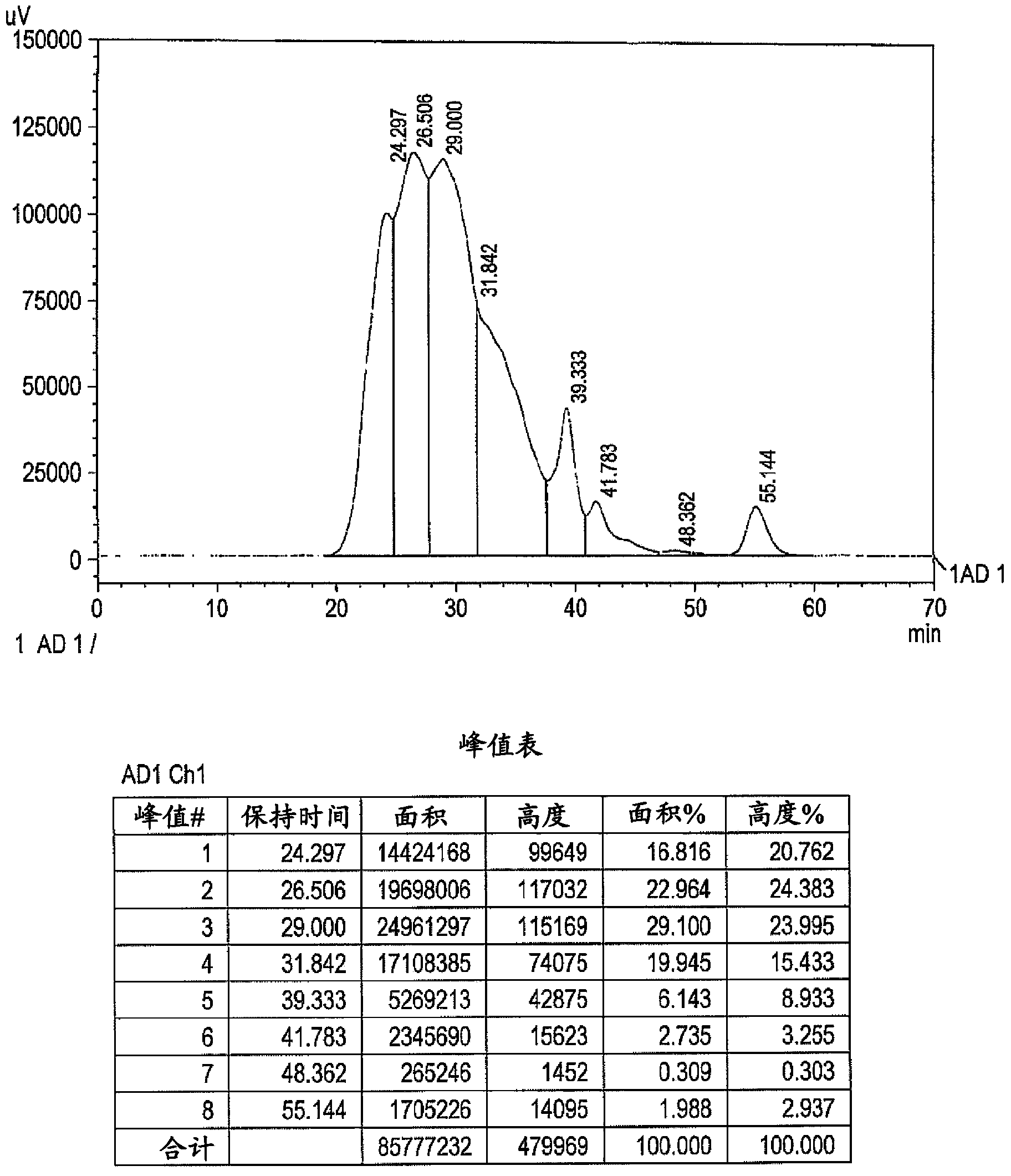

[0080] Example 3: Preparation of hydrolyzate of soybean protein (3)

[0081] Soy protein was suspended so that defatted soybean powder (trade name PROPHAM974, manufactured by ADM FAR EAST Co., Ltd.) had a concentration of 5% (w / v), and pancreas was added to the suspension so that it became 5% (w / v). Protease was reacted at 50°C for 18 hours at pH 7.5, which is near the optimal pH of the protease, and then 0.05% (w / v) of Sumizyme FL-G (manufactured by Shin Nippon Chemical Co., Ltd.) The optimum pH near 7.0 was decomposed at 60°C for 18 hours.

[0082] After completion of the reaction, the above-mentioned reactant was heat-treated at 85° C. for 15 minutes to inactivate the enzyme contained in the reactant. Next, diatomaceous earth (Fuso Chemical, RADIOLITE #200) was precoated on the Buchner funnel, and suction filtration was performed. Next, the filtrate was concentrated under reduced pressure and freeze-dried to obtain powdered soybean protein hydrolyzate in a yield of 43.9%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com