Substrate surface structured with thermally stable metal alloy nanoparticles, method for preparing the same and uses thereof, in particular as catalyst

A nanoparticle and substrate surface technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, process for producing decorative surface effects, etc., can solve the problem of catalyst loss of activity and dispersion Loss, increase in average particle size, etc., to achieve the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of Nanostructured Samples with Au / Pt Alloy Particles

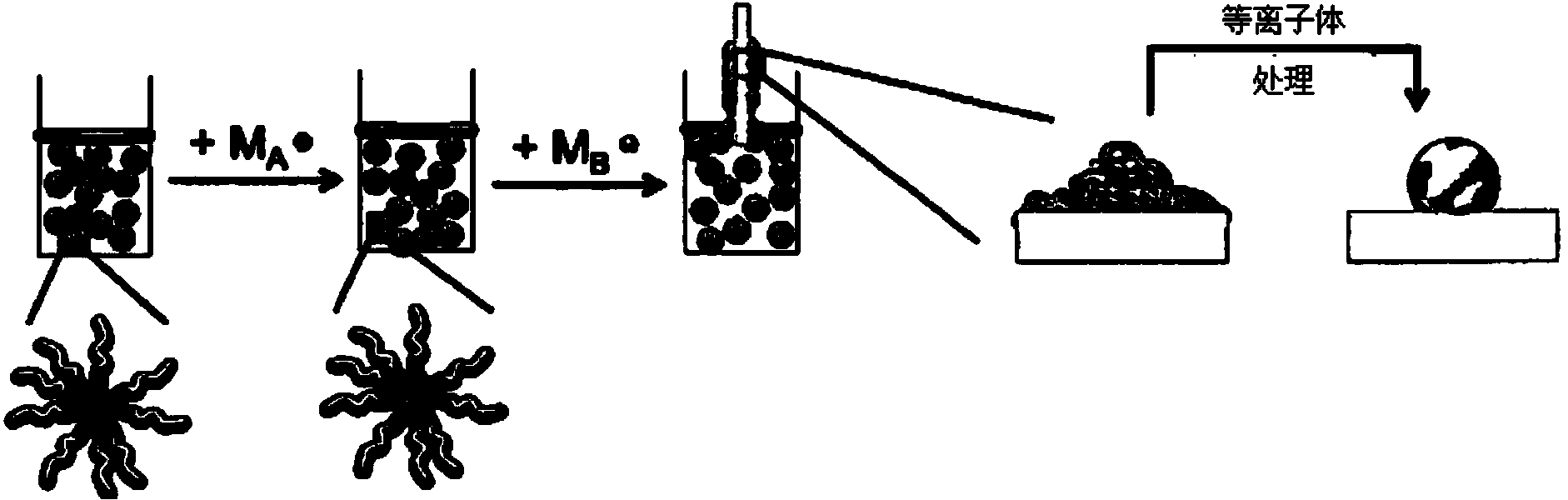

[0067] Nanostructuring of the substrate was achieved by the following general procedure developed in the inventor's research group.

[0068] The method of synthesizing alloy particles is based on the aforementioned BCML technique using at least two different metal salts in different ratios. The particle size is determined by the size of the cell and the loading of the metal salt.

[0069] In an exemplary embodiment of the method of the invention, micelles of PS(1056)-b-P2VP(495) in toluene at the desired concentration were prepared, followed by HAuCl in a ratio of 1:9-9:1 4 and H 2 PtCl 6 load. When using the first metal salt HAuCl 4 After loading the micelles, the solution was stirred for 24 h, followed by the addition of the second metal salt H 2 PtCl 6 . After addition of the second metal salt, the solution was stirred for an additional 72 h.

[0070] The micelles loaded with metal ions were ...

Embodiment 2

[0074] Characterization and Testing of Nanostructured Surfaces

[0075] The preparation of nanostructured substrate surfaces with different types of nanoparticles, as detailed in Example 1, was subjected to an artificial aging process to simulate the high operating temperatures eg in catalytic converters for automotive exhaust emissions.

[0076] The artificial aging process proceeds as follows:

[0077] In a muffle furnace, the sample was heated in air at 10°C / min to the target temperature and maintained at this temperature for 7 hours. Afterwards, the sample was allowed to cool (without applying a specific temperature gradient).

[0078] Silicon wafers are typically p-dot, conductive, and can be directly observed in a SEM with an Inlens detector without further processing (such as sputtering).

[0079] For TEM analysis, samples were prepared accordingly. Specifically, cut the sample (μm cross-section) so that electrons can transmit through the sample. EDX measurements we...

Embodiment 3

[0087] Coating microcolloids with the method of the present invention

[0088] according to Figure 6 The described protocol has coated and nanostructured microcolloidal particles.

[0089] Specifically, glass microspheres with different diameters, typically 10–100 μm, were immersed in caroic acid for 24 h, and dried after repeated rinsing with MilliQ water and sonication. To coat glass microspheres with metal nanoparticles, a column with PTFE frit was packed with microspheres. Subsequently, the column was filled with a toluene solution of a micellar polymer having a certain polymer concentration and loaded with the desired metal salt. The metal salt micellar solution is passed through the layer of glass microspheres with a slight overpressure by applying an inert gas flow, such as argon.

[0090] In a particular embodiment of nanostructuring particle surfaces with gold nanoparticles, HAuCl 4 The toluene solution of micelles loaded with PS(1056)-b-P2VP(495) polymer concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com