Cigarette filter rod loaded with nano chitosan and preparation method thereof

A nano-chitosan and filter rod technology, which is applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of small contact area, limited harm reduction effect, and difficulty in industrial production, so as to reduce the content of heavy metal substances and reduce the effect of significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

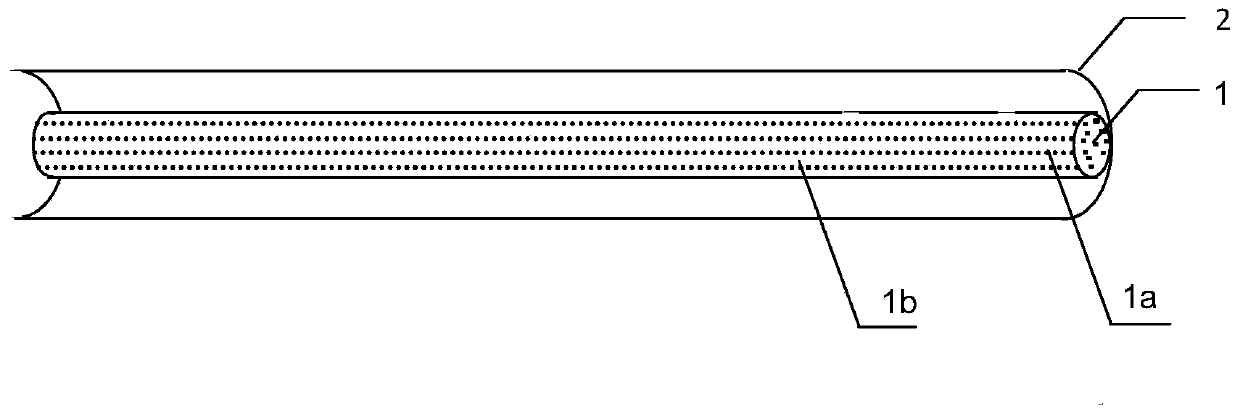

Image

Examples

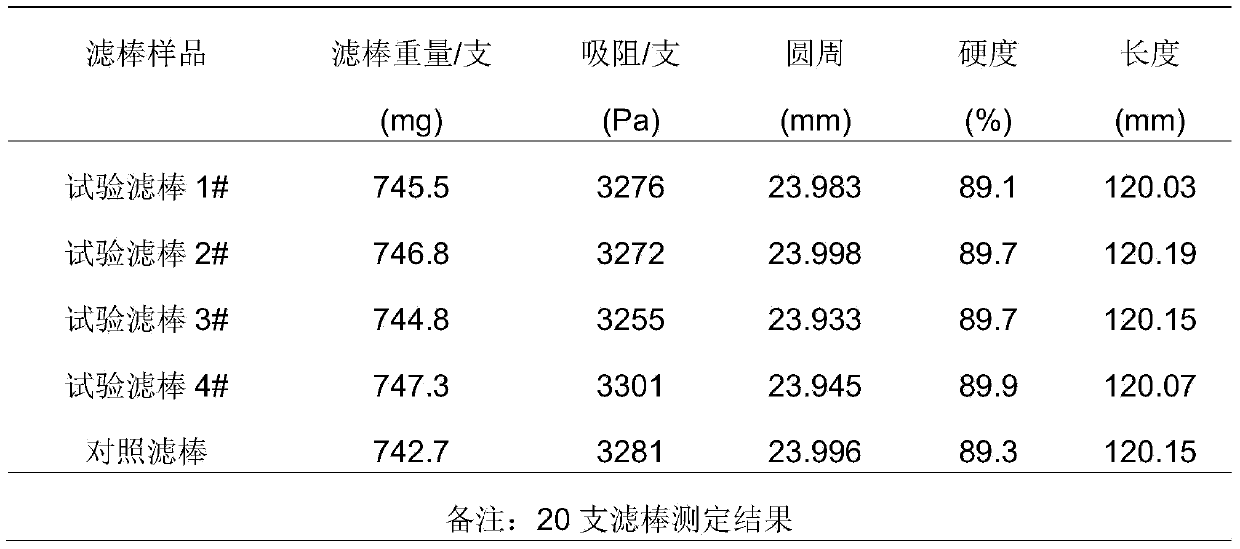

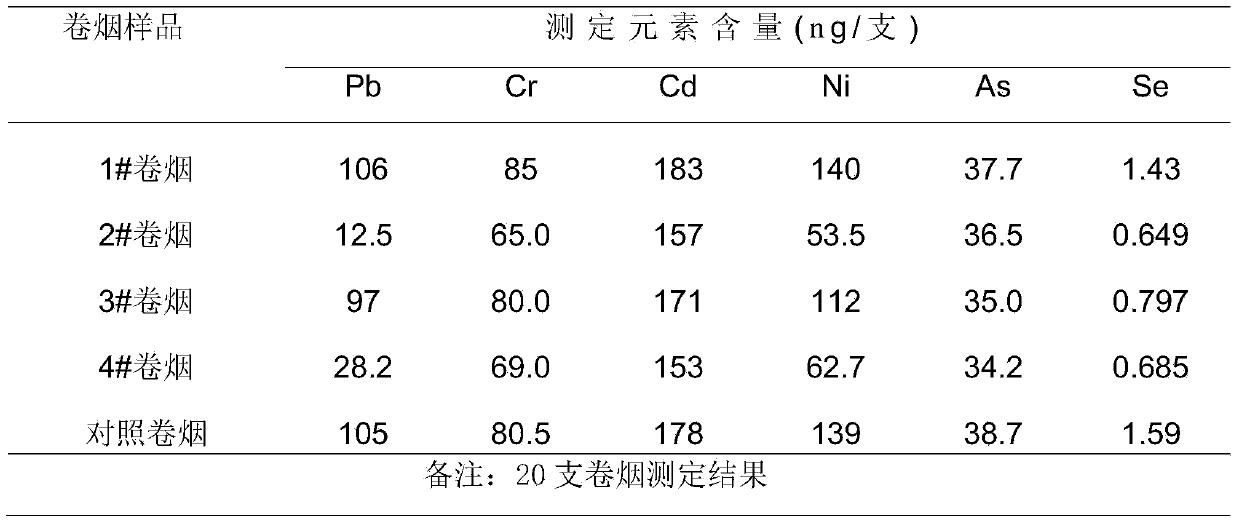

Embodiment 1

[0023] Weigh a certain amount of chitosan with a particle size less than or equal to 80 meshes, add it to the triacetin in a proportion of 7% by weight of the triacetin, and stir at a high speed to make it evenly dispersed in the triacetin to form a dispersion for later use . During the forming process of the filter rod, the chitosan / triacetin dispersion was used as a plasticizer and adhered to the surface of the acetate tow in a proportion of 8% by weight of the acetate tow. In this process, chitosan is carried by triacetin and evenly scattered on the acetate fiber tow to make a chitosan-loaded cigarette filter rod, numbered as test filter rod 1#.

Embodiment 2

[0025] A certain amount of nano-chitosan was weighed, added to triacetin in a proportion of 7% by weight of triacetin, and stirred at a high speed to make it evenly dispersed in triacetin to form a dispersion for later use. During the forming process of the filter rod, the nano-chitosan / triacetin dispersion was used as a plasticizer to adhere to the surface of the acetate fiber tow in a proportion of 8% by weight of the acetate fiber tow. In this process, nano-chitosan is carried by triacetin and evenly scattered on the cellulose acetate tow to make nano-chitosan-loaded cigarette filter rods, numbered as test filter rod 2#.

Embodiment 3

[0027] A certain amount of nano-chitosan was weighed, added to triacetin in a proportion of 3.5% of the weight of triacetin, and stirred at a high speed to make it evenly dispersed in triacetin to form a dispersion for use. During the forming process of the filter rod, the nano-chitosan / triacetin dispersion was used as a plasticizer to adhere to the surface of the acetate fiber tow in a proportion of 8% by weight of the acetate fiber tow. In this process, nano-chitosan is carried by triacetin and evenly scattered on the acetate fiber bundles to make nano-chitosan-loaded cigarette filter rods, numbered as test filter rod 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com