Polyacrylate dispersant, pigment dispersion, color photoresist, color film substrate and display device

A polyacrylate and pigment dispersion technology, applied in optics, optical components, opto-mechanical equipment, etc., can solve the problems of poor controllability of dispersant POSS modification, affecting the performance of color photoresist, poor stability of pigment liquid, etc. Achieve the effect of excellent resolution, excellent surface flatness, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

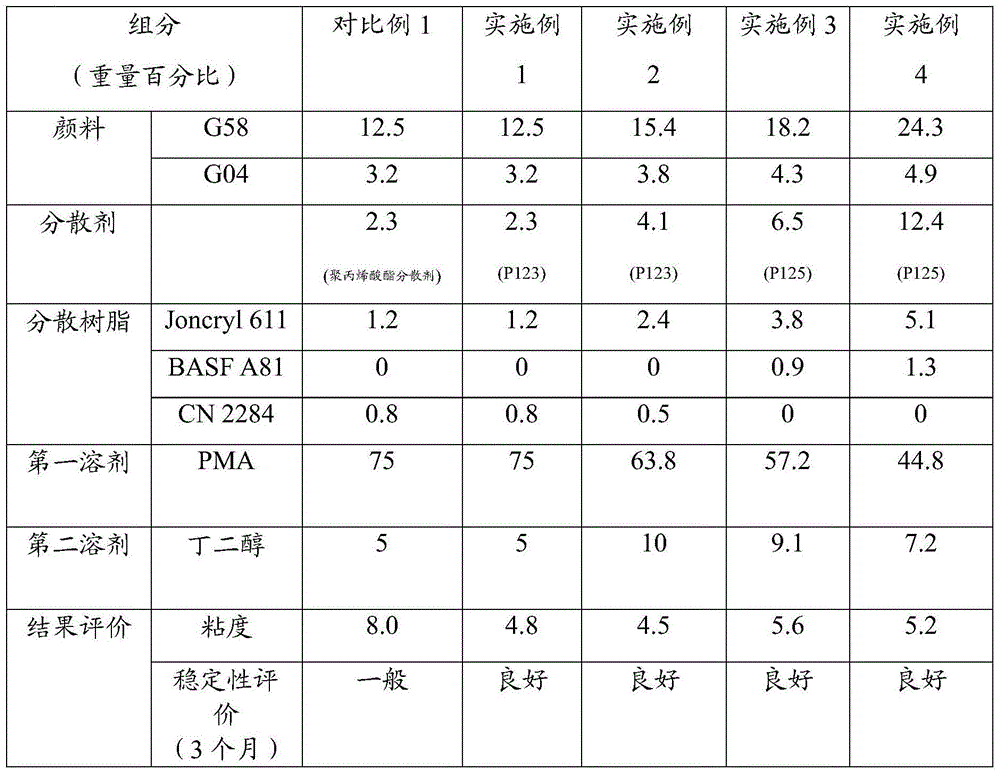

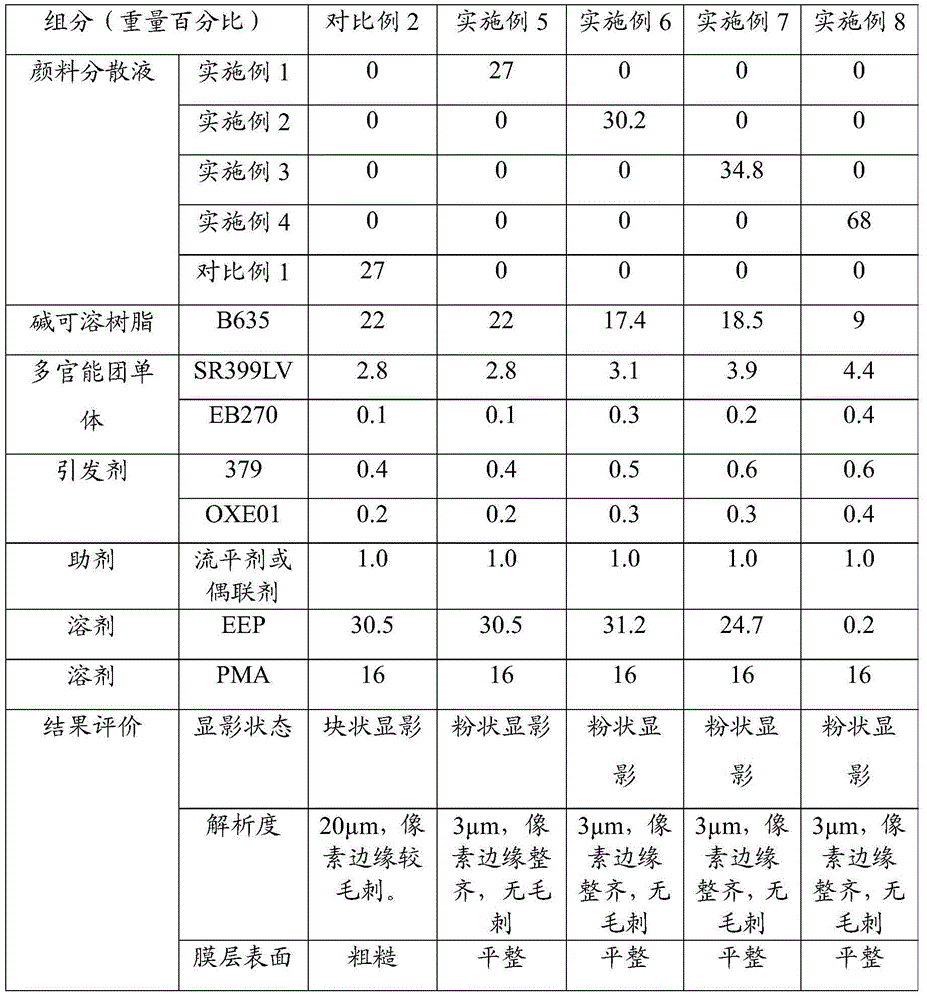

[0028] When the POSS modified polyacrylate dispersant of the present invention is used to disperse pigment powder, due to the steric hindrance effect of the POSS structure, the stability of the pigment dispersion can be significantly improved.

[0029] The POSS modified polyacrylate dispersant of the present invention is prepared by esterifying the polyacrylate dispersant and POSS. When it is used to disperse pigment powder, it can improve the stability of pigment dispersion due to the steric hindrance effect of POSS structure.

[0030] For example, the POSS modified polyacrylate dispersant of the present invention is based on amide condensation agents such as 1-hydroxybenzotriazole (HOBt) and 1-(3-dimethylaminopropyl)-3-ethyl Under the catalysis of diimine (EDC) and POSS through esterification reaction, POSS is modified on the polyacrylate dispersant, and the POSS modified polyacrylate dispersant is obtained.

[0031] The molecular formula of POSS is (SiO 1.5 ) m (C 6 h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com