A kind of preparation method of aluminum modified silica sol

A technology of silica sol and aluminum modification, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

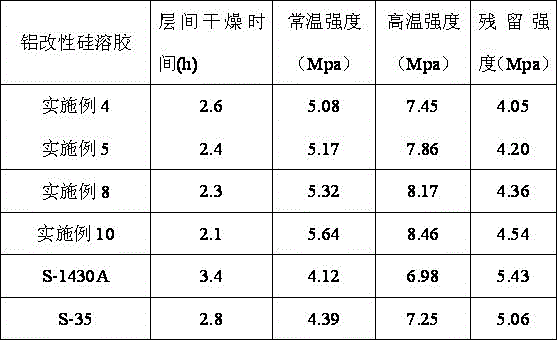

Examples

Embodiment 1

[0021] Take 2.00g NaOH, add to 550mLH with stirring 2 Heat to dissolve in O, continue to heat up to 90-100°C, then add a mixture of 28.00g Si powder and 0.10g Al powder, react for 5-8 hours, cool to room temperature, and filter to obtain 500g milky white sol. The aluminum modified silica sol SiO 2 The content is 12.00%, the pH value is 10.58, and the aluminum content is 200ppm.

Embodiment 2

[0023] Take 3.00g NaOH, add to 550mLH with stirring 2 Heat to dissolve in O, continue to heat up to 90-100°C, then add a mixture of 28.00g Si powder and 0.10g Al powder, react for 5-8 hours, cool to room temperature, filter and concentrate under reduced pressure to obtain 120g milky white sol, the aluminum modified Silica sol SiO 2 The content is 50.00%, the pH value is 10.65, and the aluminum content is 833ppm.

Embodiment 3

[0025] Take 3.00g NaOH, add to 550mLH with stirring 2 Heat to dissolve in O, continue to heat up to 90-100°C, then add a mixture of 28.00g Si powder and 0.10g Al powder, react for 5-8 hours, cool to room temperature, filter and concentrate under reduced pressure to obtain 240g off-white transparent sol, the aluminum Modified silica sol SiO 2 The content is 25.00%, the pH value is 10.68, and the aluminum content is 416ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com