Method for improving catalytic activity of denitration catalyst

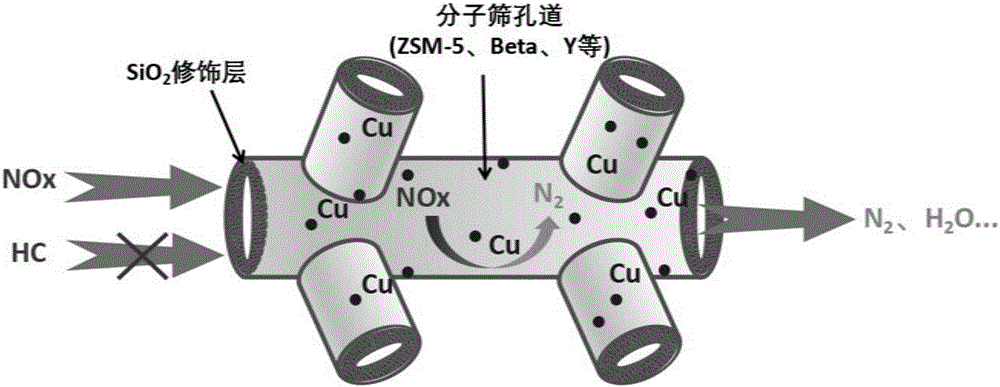

A denitrification catalyst, high catalytic activity technology, applied in the field of denitrification catalysis, can solve the problems of stability gap, large pore structure, catalyst deactivation, etc., to prevent the entry of hydrocarbon molecules, improve catalytic stability and catalyst life, Effect of suppressing carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

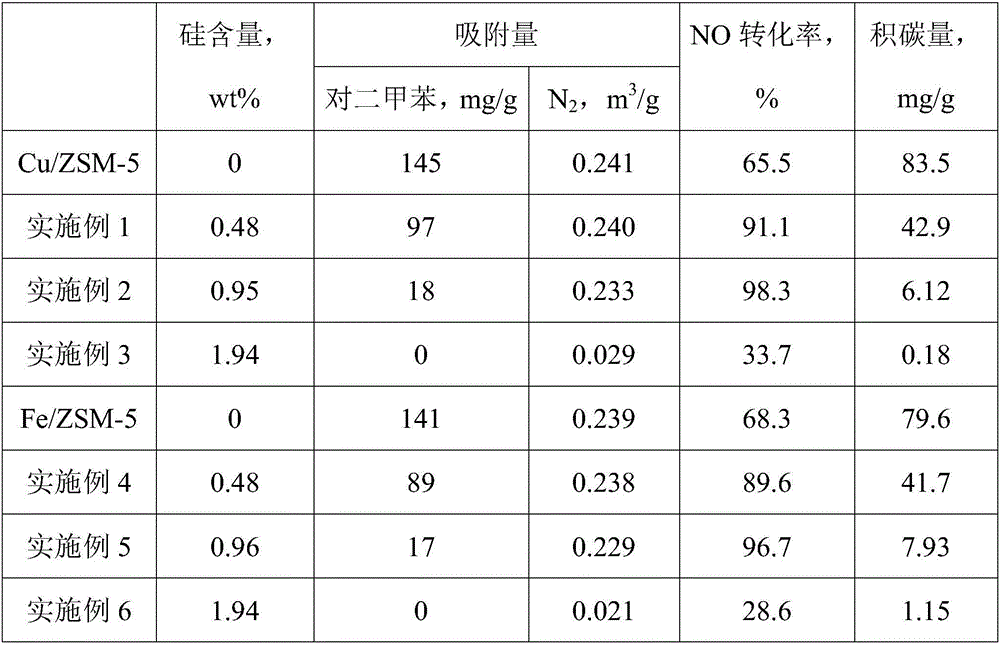

Embodiment 1

[0027] A method for improving the catalytic activity of a denitration catalyst, comprising the steps of:

[0028] S1. Add copper-based ZSM-5 molecular sieve to n-hexane, then add tetraethyl orthosilicate and stir evenly. The mass-volume ratio (g / mL) of copper-based ZSM-5 molecular sieve to tetraethyl orthosilicate is 1:0.15. The volume ratio of n-hexane to tetraethyl orthosilicate is 25:0.15, reflux in a water bath at 90°C for 1 hour, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 4 hours to obtain the first material;

[0029] S2. Add the first material to n-hexane, then add orthosilicate ethyl ester and stir evenly. The mass volume ratio (g / mL) of the first material to orthosilicate ethyl ester is 1:0.15, n-hexane and orthosilicate The volume ratio of ethyl ester is 25:0.15, reflux in a water bath at 90°C for 1 hour, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 4 hours to obtain the second material;

[0030] S3, repeating S...

Embodiment 2

[0032] A method for improving the catalytic activity of a denitration catalyst, comprising the steps of:

[0033] S1. Add copper-based ZSM-5 molecular sieve to n-hexane, then add tetraethyl orthosilicate and stir evenly. The mass-volume ratio (g / mL) of copper-based ZSM-5 molecular sieve to tetraethyl orthosilicate is 1:0.18. The volume ratio of n-hexane to tetraethyl orthosilicate is 20:0.18, reflux in a water bath at 90°C for 1 hour, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 4 hours to obtain the first material;

[0034] S2. Add the first material to n-hexane, then add orthosilicate ethyl ester and stir evenly. The mass volume ratio (g / mL) of the first material to orthosilicate ethyl ester is 1:0.18, n-hexane and orthosilicate The volume ratio of ethyl ester is 20:0.18, reflux in a water bath at 90°C for 1h, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 4h to obtain the second material;

[0035] S3, repeating S2 until t...

Embodiment 3

[0037] A method for improving the catalytic activity of a denitration catalyst, comprising the steps of:

[0038] S1. Add copper-based ZSM-5 molecular sieve to n-hexane, then add tetraethyl orthosilicate and stir evenly. The mass-volume ratio (g / mL) of copper-based ZSM-5 molecular sieve to tetraethyl orthosilicate is 1:0.16. The volume ratio of n-hexane to tetraethyl orthosilicate is 25:0.18, reflux in a water bath at 90°C for 1 hour, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 5 hours to obtain the first material;

[0039] S2. Add the first material to n-hexane, then add tetraethyl orthosilicate and stir evenly, the mass volume ratio (g / mL) of the first material to orthosilicate ethyl ester is 1:0.16, n-hexane and orthosilicate The volume ratio of ethyl ester is 25:0.18, reflux in a water bath at 90°C for 1h, filter, dry the filter cake, and roast in a muffle furnace at 500°C for 5h to obtain the second material;

[0040] S3, repeating S2 until th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com