Preparation method of oxidized polyethylene wax emulsion

A technology for oxidizing polyethylene wax and emulsion, applied in the field of polymer materials, can solve the problems of large fluctuation of product stability, high cost of raw materials, water pollution, etc., to avoid poor stability, excellent application performance, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

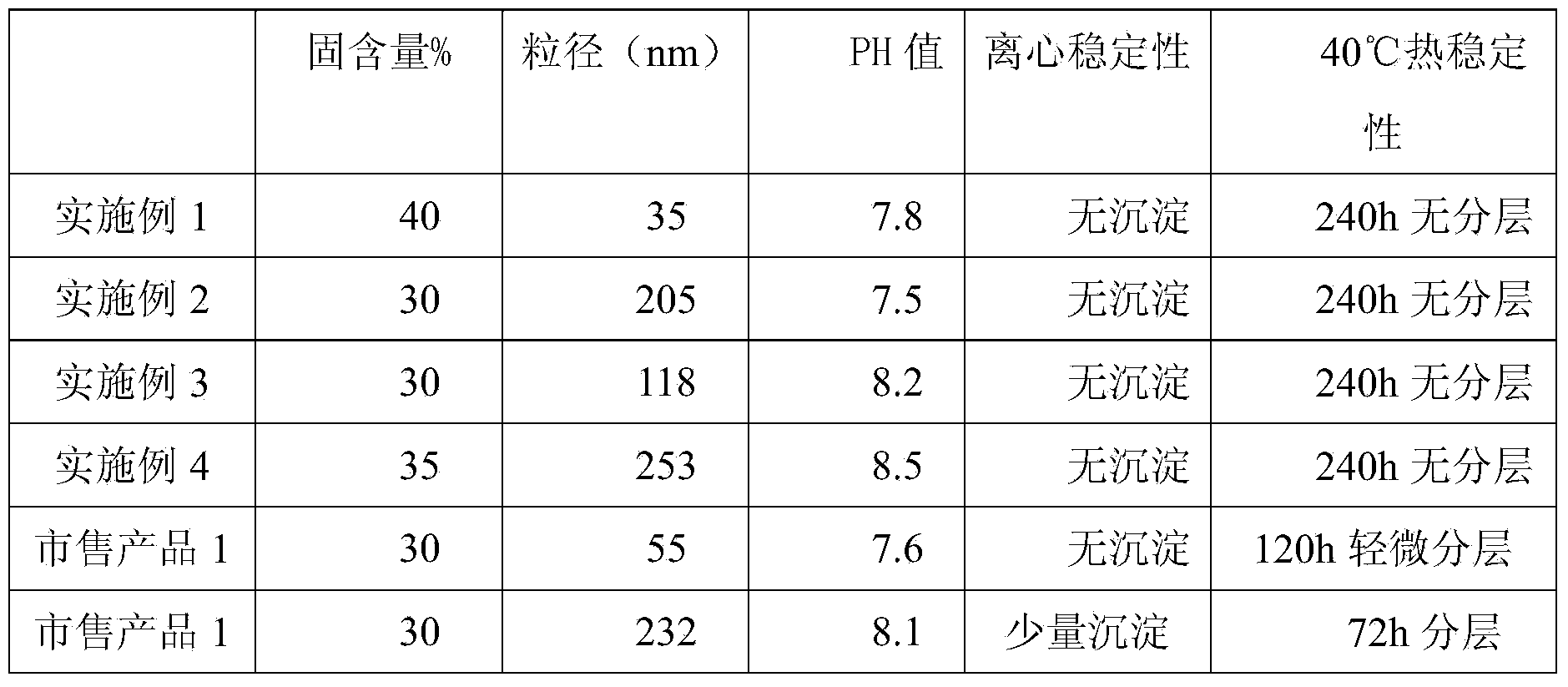

Examples

Embodiment 1

[0032] Take by weighing BASF Luwax OA210g, HLB value 12.8 nonionic composite emulsifier 63g, described nonionic composite emulsifier is obtained by compounding of isomeric tridecyl alcohol polyoxyethylene ether 1307 and 1312 of German Bessmann; Add 8.5g of potassium and 80g of deionized water into the autoclave, seal it and feed high-pressure nitrogen to make the pressure in the autoclave reach 0.15MPa, stir and heat at 500rpm to the set emulsification temperature of 120°C, then react at 8.5ml / min Add 342g of deionized water at 90-95°C dropwise to the tank for 40 minutes. After the dropwise addition, cool down to room temperature to obtain a microemulsion of oxidized polyethylene wax with a particle size of 35nm and a solid content of 40%.

Embodiment 2

[0034] Take by weighing BASF Luwax OA210g, 42.0g of nonionic emulsifier with HLB value 12.8, described nonionic emulsifier is obtained by compounding of isomeric tridecyl alcohol polyoxyethylene ether 1307 and 1312 of German Bessman; Potassium hydroxide Add 8.5g of deionized water and 80g of deionized water into the high-pressure reaction kettle, and then inject high-pressure nitrogen gas after sealing to make the pressure in the kettle reach 0.15MPa. Stir at 350rpm and heat up to the set emulsification temperature of 120°C. Add 530 g of deionized water at 90-95°C dropwise for 55 minutes. After the dropwise addition, cool down to room temperature to obtain an oxidized polyethylene wax emulsion with a particle size of 205 nm and a solid content of 30%.

Embodiment 3

[0036] Weigh 58.8g of nonionic emulsifier of BASF Luwax OA2210g, HLB value 12.5, described nonionic emulsifier is obtained by compounding of isomeric tridecyl alcohol polyoxyethylene ether 1306 and 1312 of German Bessman; Potassium hydroxide Add 9.0g of deionized water and 85g of deionized water into the high-pressure reaction kettle, and then inject high-pressure nitrogen gas after sealing to make the pressure inside the kettle reach 0.25MPa. 563g of deionized water at 90-95°C was added dropwise for 60 minutes. After the dropwise addition, the temperature was cooled to room temperature to obtain an oxidized polyethylene wax emulsion with a particle size of 118nm and a solid content of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com