Mask and preparation method and application of mask

A mask and substrate technology, applied in the field of masks, can solve the problems of poor stability, influence of evaporation accuracy, poor accuracy, etc., and achieve the effects of improving accuracy, high alignment accuracy, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

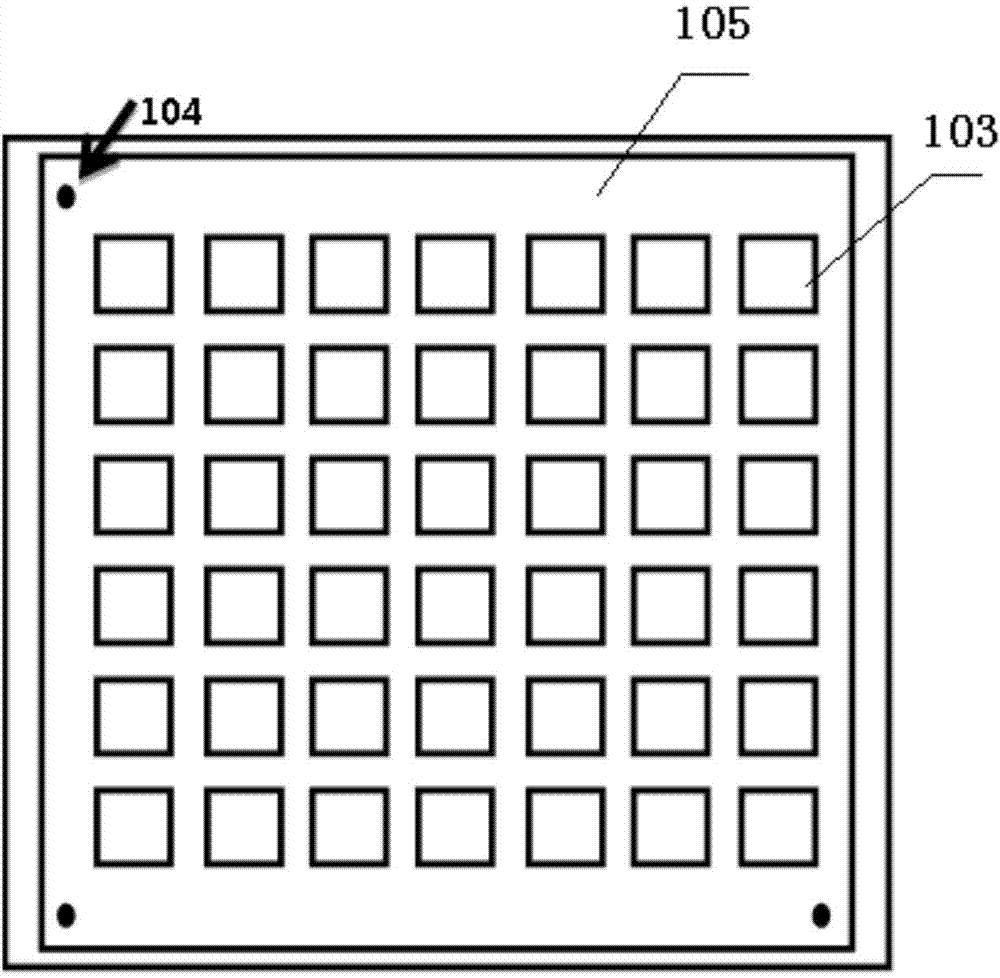

[0043] In this embodiment, a mask plate, such as figure 1 with image 3As shown, it includes a magnetic flexible film 105 and several openings 103 formed on the flexible film 105 and passing through the flexible film.

[0044] In the mask plate in this embodiment, the process of preparing the opening 103 on the flexible film 105 can be laser etching, so the precision requirement of the opening 103 can be guaranteed. It should be noted that the size and shape of the opening 103 in this embodiment are determined according to the requirements during actual evaporation. It may be a circular opening, a square opening, a rectangular opening, or even a polygonal or other special-shaped opening. It may have a square shape of 10 μm×10 μm, or a rectangular shape of 10 μm×20 μm. figure 1 What is shown in is a square-shaped opening, but the laser etching used in this embodiment can meet the requirements of different shapes and precision.

[0045] from figure 1 It can also be seen fro...

Embodiment 2

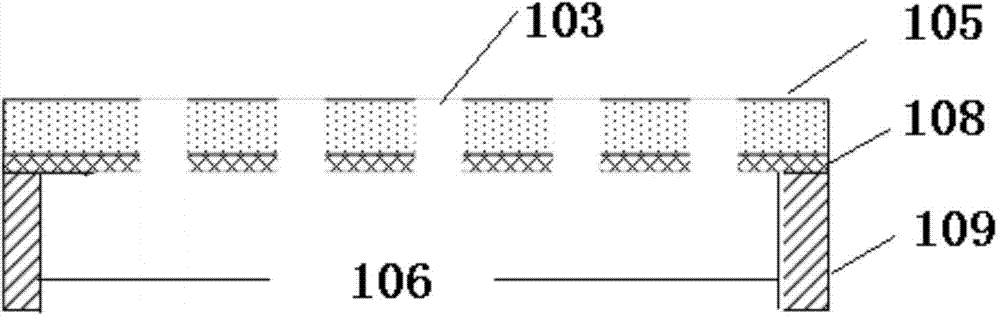

[0055] The mask plate described in this embodiment, on the basis of Embodiment 1, such as figure 2 As shown, it also includes a support frame 109 supporting the flexible film 105, and a second opening 106 passing through the support frame is formed on the support frame 109, and the size of the second opening 106 is larger than that of the flexible film. The size of the opening 103 .

[0056] In the above scheme in this embodiment, the support frame 109 is to provide support for the flexible film 105, and its material can be selected from any material with strong rigidity that can be applied to the mask plate, such as Invar material, SUS420 steel material, etc. . Therefore, the size of the second opening 106 prepared thereon can be large, for example, 40 μm×40 μm, 100 mm×100 mm, 5 cm×5 cm, etc. can be selected. It can be seen from the figure that the size of the second opening 106 is several times that of the opening 103 . In the actual process, it can also be determined ac...

Embodiment 3

[0060] This embodiment provides a method for preparing a mask, such as Figure 4 shown, including the following steps:

[0061] S1: Prepare the flexible film 105 by using a flexible material added with a magnetic material, wherein the proportion of the magnetic material is between 5-25%, preferably 5-15%.

[0062] S2: using a laser etching process to prepare an opening 103 on the flexible film 105 to obtain a mask.

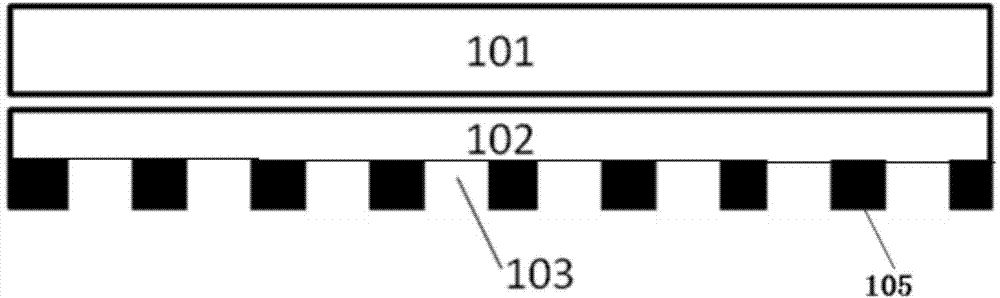

[0063] In the above solution in this embodiment, the laser etching process has higher precision than the wet etching process. Moreover, the mask plate obtained by this method has good flexibility, and the mask plate is magnetic, and the mask plate can be directly attached to the substrate 102, which avoids the problem caused by the insecure fixation of the mask plate in the prior art. Alignment deviation.

[0064] As an achievable manner, in the step S1, the flexible film is prepared by stretching the flexible material added with the magnetic material by a melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com