Preparation of nickel-base single-crystal high-temperature alloy through light floating zone melting directional solidification method

A technology of directional solidification and nickel-based single crystal, which is applied in the directions of directional solidification, single crystal growth, and single crystal growth of eutectic materials. Uniform, easy-to-control results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The composition of this embodiment is shown in Table 1

[0024] Table 1

[0025] Cr co Mo W Ta Re Al f C B Y Ni 7 7.5 1.5 5 6.5 3 6.2 0.15 0.05 0.004 0.01 balance margin

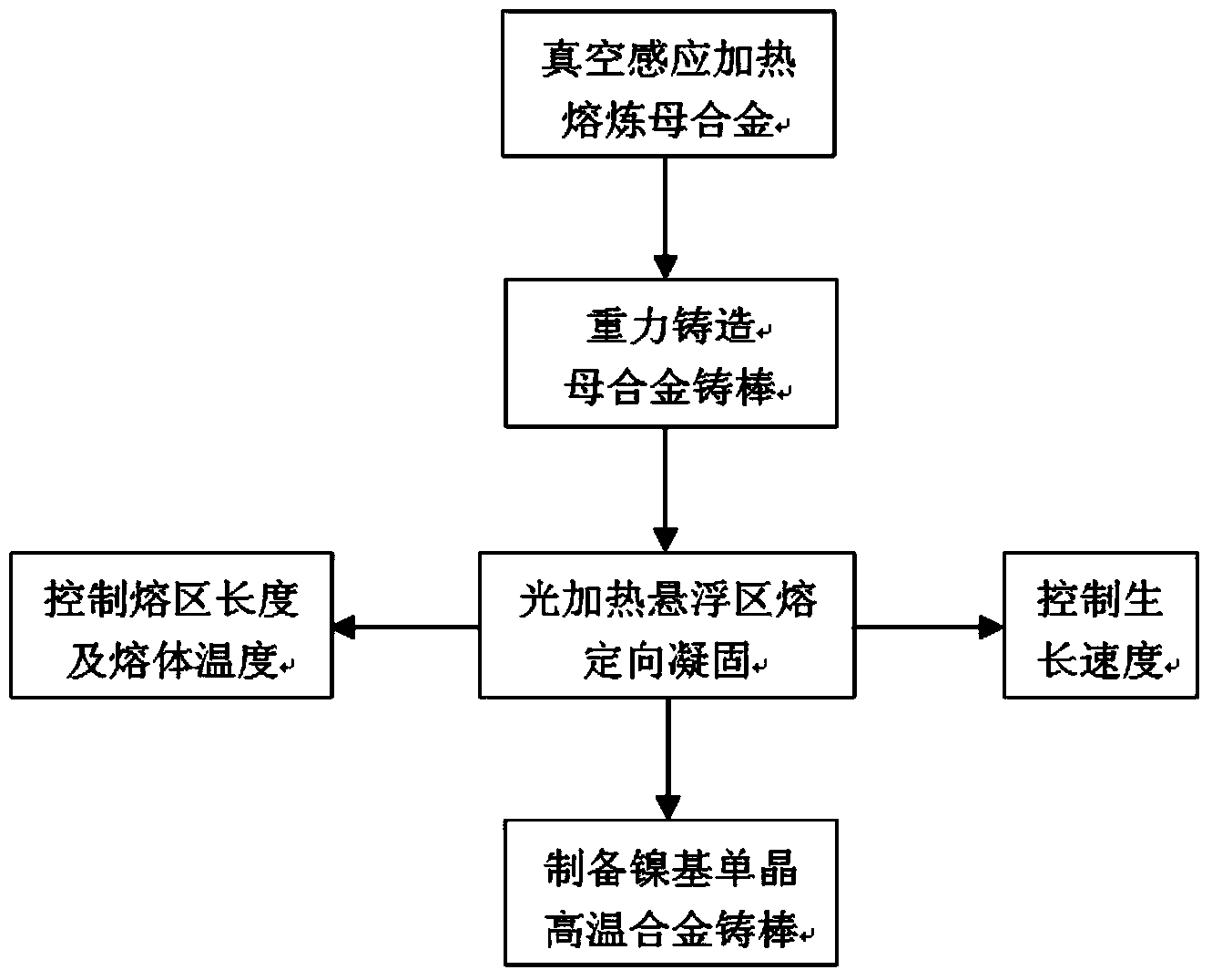

[0026] (1) Vacuum induction heating and melting master alloy;

[0027] (2) Preparation of master alloy cast rods by gravity casting Φ6×100mm;

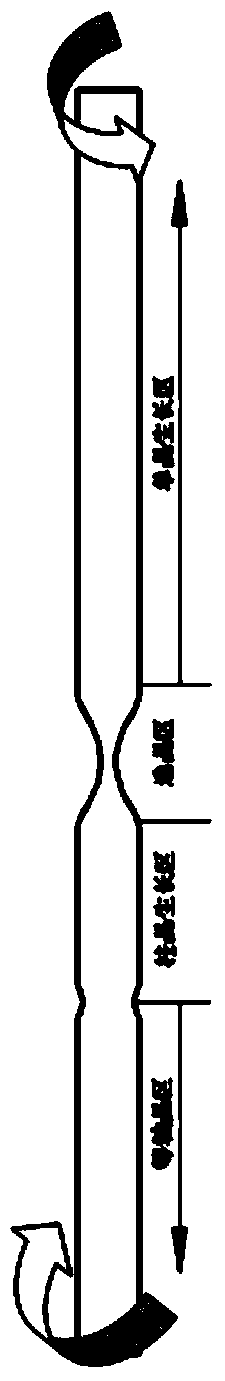

[0028] (3) Vacuum to 3×10 -3 Pa, flow argon gas at 5L / min, carry out regional melting and directional solidification, control the length of the melting zone at 5mm, melt temperature at 1450°C, crystal growth rate at 5mm / h, and prepare nickel-based single crystal superalloy casting rod Φ6× 50mm;

[0029] (4) Organizational observation: such as image 3 As shown, the structure is relatively uniform without obvious component segregation.

Embodiment 2

[0031] The composition of this embodiment is shown in Table 2

[0032] Table 2

[0033] Cr co Mo W Ta Al f C B Y Ni 7.5 5 2 8 6.5 6.1 0.15 0.05 0.004 0.015 balance margin

[0034] (1) Vacuum induction heating and melting master alloy;

[0035] (2) Preparation of master alloy cast rods by gravity casting Φ4×100mm;

[0036] (3) Vacuum to 3×10 -3 Pa, flow argon gas at 5L / min, conduct regional melting and directional solidification, control the length of the melting zone at 5mm, melt temperature at 1450°C, crystal growth rate at 2mm / h, and prepare nickel-based single crystal superalloy casting rod Φ6× 100mm.

Embodiment 3

[0038] The composition of this embodiment is shown in Table 3

[0039] table 3

[0040] Cr co Mo W Ta Al f C B Y Ni 7 7.5 2 8 6.5 6.1 0.15 0.05 0.004 0.015 balance margin

[0041] (1) Vacuum induction heating and melting master alloy;

[0042] (2) Preparation of master alloy cast rods by gravity casting φ9×100mm;

[0043] (3) Vacuum to 3×10 -3 Pa, flow argon gas at 5L / min, carry out regional melting and directional solidification, control the length of the melting zone at 5mm, melt temperature at 1450°C, crystal growth rate at 1mm / h, and prepare nickel-based single crystal superalloy casting rod Φ9× 500mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com