Magnetoelectric composite material and preparation method thereof

A magnetoelectric composite material and air piezoelectric technology, which is applied in the selection of materials, the manufacture/processing of electromagnetic devices, etc., can solve the problem of difficult adjustment of magnetic phase volume fraction, composite materials without piezoelectricity, and low magnetostrictive phase Resistance and other issues, to achieve significant magnetoelectric effect, good magnetoelectric effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of PZT annular green body

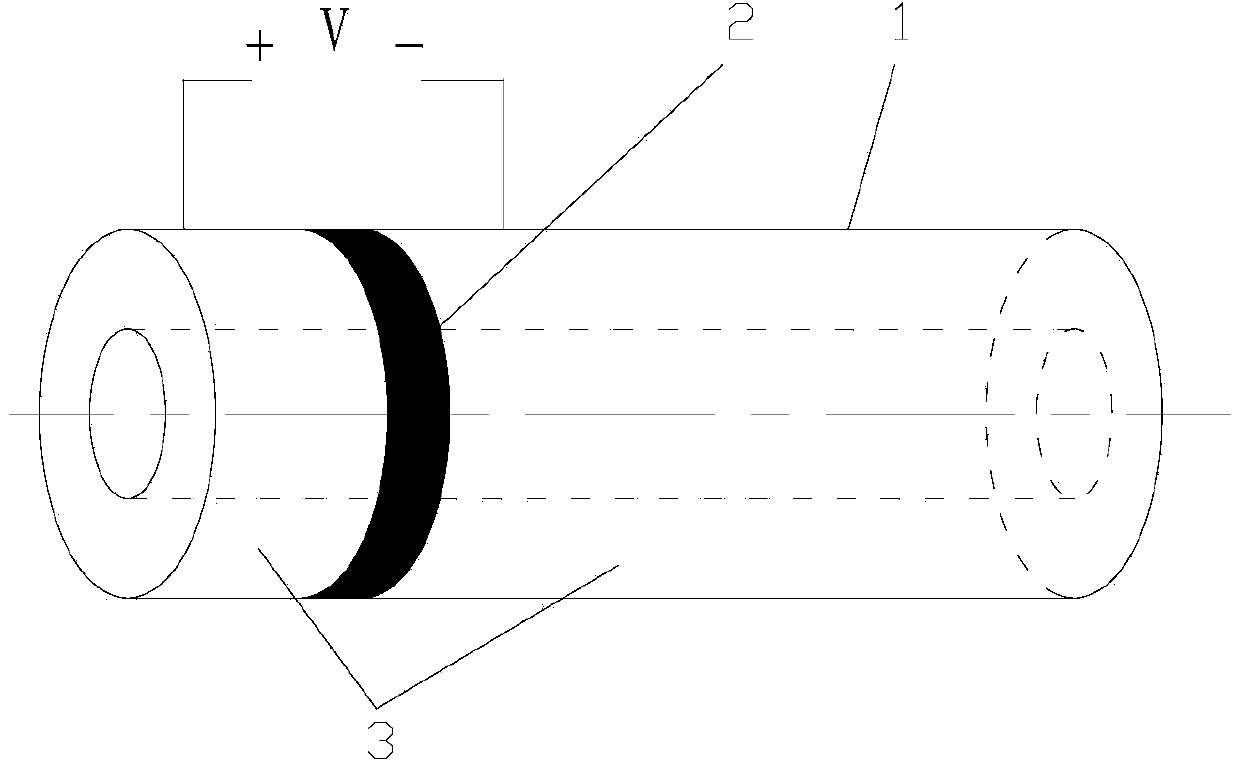

[0035]Using PZT-5A powder as raw material, adding glycerol as a plasticizer, adding polyvinyl alcohol as a binder, and using viscous plastic processing technology to obtain a slurry with high solid content. The mass ratio of PZT-5A powder, polyvinyl alcohol binder and glycerol plasticizer is 30:4:1. Extrude the slurry to obtain a hollow PZT green body, the outer diameter of the green body is 20 mm, the inner diameter is 15 mm, and the inner wall of the PZT green body is coated with platinum slurry.

[0036] (2) Preparation of carbon black green body

[0037] Using acetylene black powder as raw material, adding glycerol as a plasticizer, adding polyvinyl alcohol as a binder, and using viscous plastic processing technology to obtain a slurry with high solid phase content. Wherein the mass ratio of carbon black, polyvinyl alcohol binder and glycerol plasticizer is 30:4:1. Slurry is extruded to make cylindrical carbon black gre...

Embodiment 2

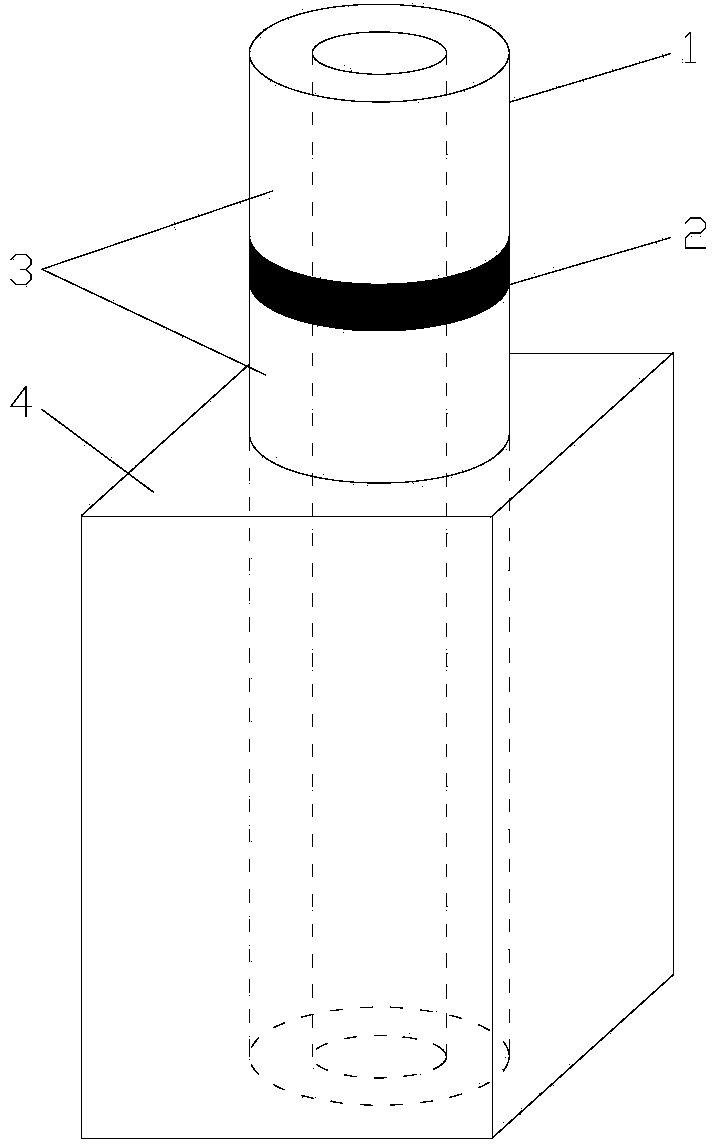

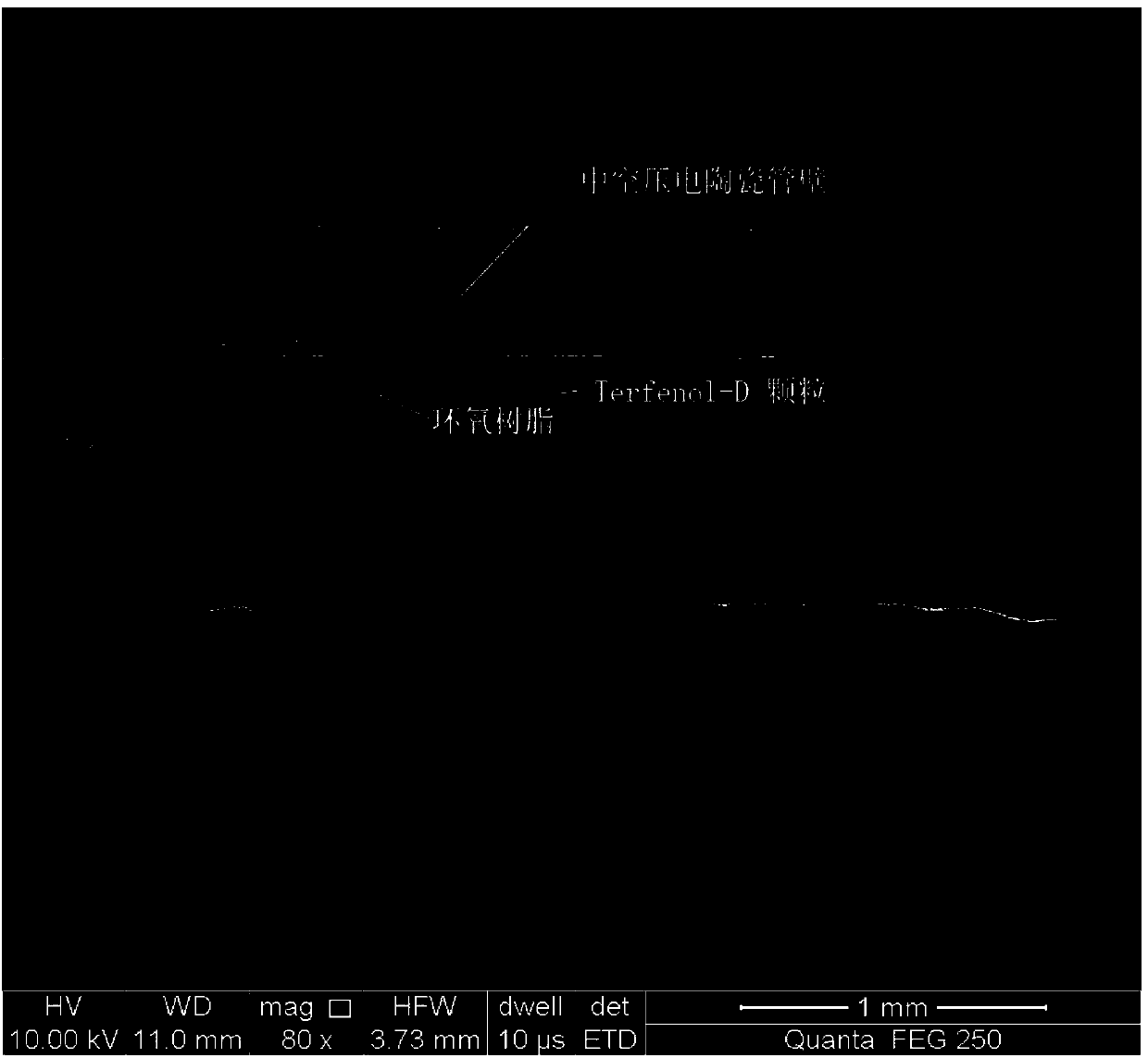

[0047] Using textured PMN-PT powder and acetylene black as raw materials, obtain hollow piezoelectric fibers according to the co-extrusion process described in Example 1, wherein the inner diameter of the obtained hollow piezoelectric fibers is 80 μm, and the outer diameter is 200 μm. The fibers were polarized in silicone oil at 100°C for 30 min at a polarizing electric field of 3 kV / mm. The magnetostrictive particle Terfenol-D is mixed with E-42 epoxy resin, wherein the particle size of Terfenol-D particle is 40 μm, NiFeO 4 The volume fraction in the mixture is 51%. The above-mentioned hollow piezoelectric fiber is erected vertically in a paraffin mold of 3mm*3mm*10mm, and the mixture of magnetostrictive particles and epoxy resin is filled into the mold, cured at a vacuum degree of 40kPa for 18h, and the magnetoelectric fiber is obtained after mechanical processing. composite material. The obtained performance: the maximum value of the magnetoelectric conversion coefficient...

Embodiment 3

[0049] Using PZT-5A powder and acetylene black as raw materials, obtain hollow piezoelectric fibers according to the co-extrusion process described in Example 1, wherein the inner diameter of the obtained hollow piezoelectric fibers is 273 μm, and the outer diameter is 610 μm. Polarize in silicone oil for 30min at a polarization electric field of 3kV / mm. Firstly, the magnetostrictive particles Terfenol-D and FeBSiC were mixed together with E-42 epoxy resin, wherein the particle size of Terfenol-D was 40 μm, the particle size of FeBSiC was 45 μm, and the volume fraction of Terfenol-D in the mixture was 35%, and the volume fraction of FeBSiC in the mixture is 30%. The above-mentioned hollow piezoelectric fiber is erected vertically in a 3mm*3mm*10mm paraffin mold, and the mixture of magnetostrictive particles and epoxy resin is filled into the mold, cured at a vacuum degree of 40kPa for 12h, and the magnetoelectric fiber is obtained after mechanical processing. composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com