Curable resin composition

A curable resin and composition technology, applied in the direction of non-polymer organic compound adhesives, synthetic resin layered products, cellulose plastic material layered products, etc. Display unevenness and other problems, achieve the effect of high adhesion durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Hereinafter, the present invention will be described in more detail with reference to experimental examples, but the present invention is not limited thereto. In addition, each component in the curable resin composition described in an Example selected the following compounds.

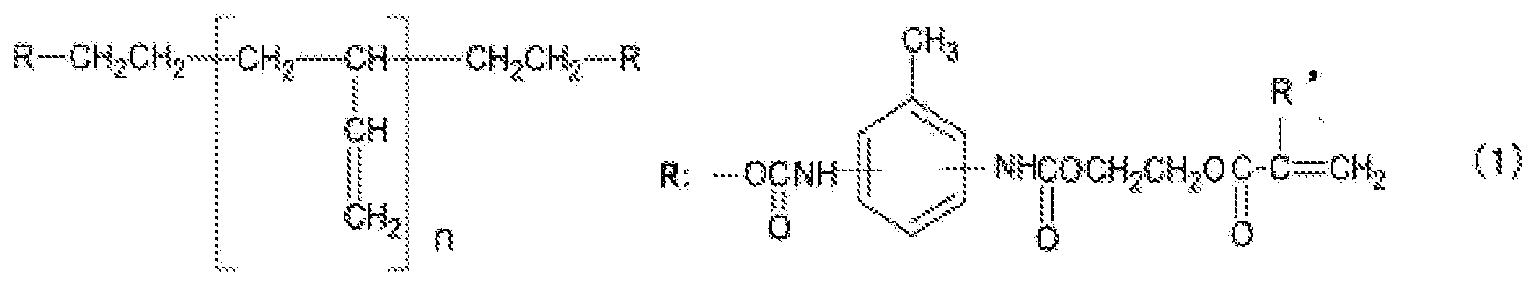

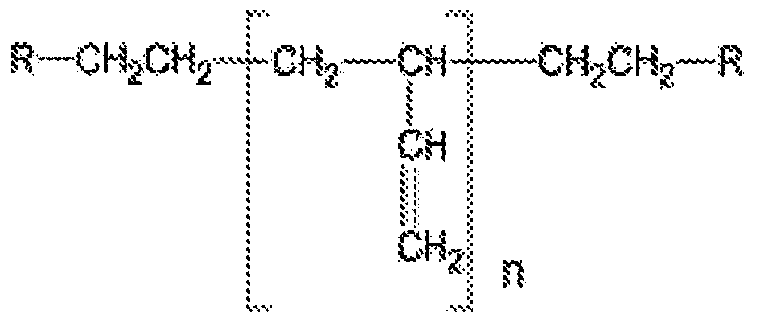

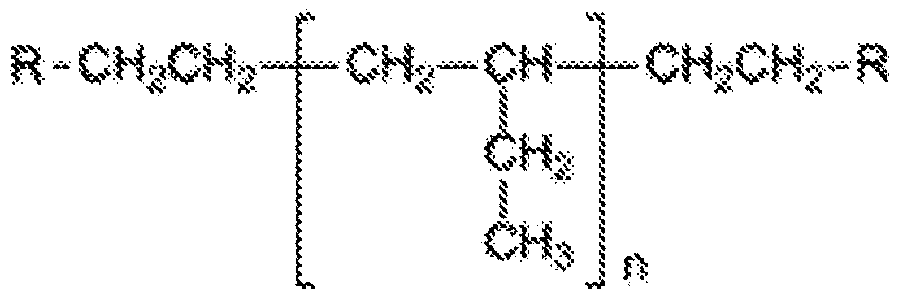

[0109] As selected from polyurethane-based (meth)acrylate oligomers, polyester-based (meth)acrylate oligomers, polyether-based (meth)acrylate oligomers, epoxy-based (meth)acrylate One or more of the group consisting of an oligomer, a diene polymer-based (meth)acrylate oligomer, and an oligomer having a skeleton of a hydrogenated product of a diene polymer-based (meth)acrylate (meth)acrylate oligomer (A),

[0110] (A-1) 1,2-polybutadiene-modified polyurethane-based methacrylate oligomer ("TE-2000" manufactured by Nippon Soda Co., Ltd.) (polystyrene-equivalent number average molecular weight obtained by GPC 2000, 2 functional methacrylate oligomers)

[0111] (A-2) Mixture of acrylate polymer an...

experiment example )

[0150] Curable resin compositions having the compositions shown in Tables 1 to 4 were prepared, and various physical properties were measured. The results are shown in Tables 1-4.

[0151] [Table 1]

[0152]

[0153] [Table 2]

[0154]

[0155] [table 3]

[0156]

[0157] [Table 4]

[0158]

[0159] From this experimental example, the following matters are known. The present invention has high adhesiveness. The present invention has flexibility to the extent that it can follow the deformation of the adherend under a heated environment, and thus has high moisture and heat resistance. When DMDO, which is a compound having two or more mercapto groups, is used, the flexibility and adhesiveness are low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com