Single-coating type metal and rubber heat vulcanization adhesive and preparation method thereof

A thermal vulcanization and adhesive technology, used in the field of metal and rubber bonding adhesives, can solve problems such as bonding surface attenuation, and achieve excellent peel strength and crosslinking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 3

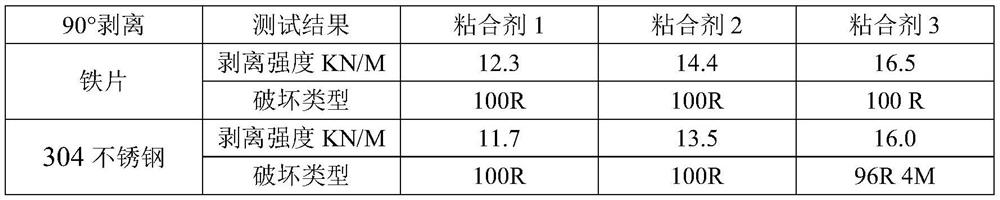

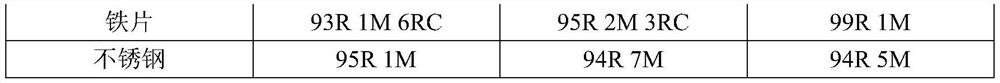

[0053] Example 1 Example 2 Example 3 Diels-Alder graft polymer (%) 10.3 9.4 8.90 Liquid polybutadiene rubber (%) 4.0 5.8 6.85 Resorcinol (%) 2.4 2.2 2.05 Hexamethylenetetramine (%) 2.4 2.2 2.05 p-Benzoquinonedioxime (%) 1.6 1.4 1.37 selenium(%) 0.8 0.7 0.68 Zinc oxide(%) 1.6 1.4 1.37 Fumed silica (%) 0.8 0.7 0.68 Carbon black (%) 1.2 1.1 1.03 Organic solvents(%) 75.0 75.0 75.0 total(%) 100 100 100

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com