Polarizing element and polarizing plate

A polarizing element and polarizer technology, which is applied in the field of dye-based polarizing elements and polarizers, can solve the problems of low transmittance and low contrast of dye-based polarizers, and achieve the effect of improving optical characteristics and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

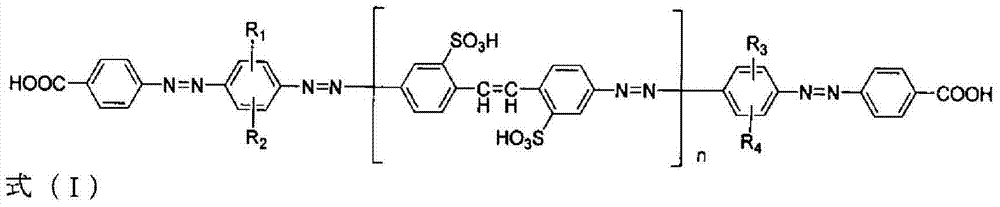

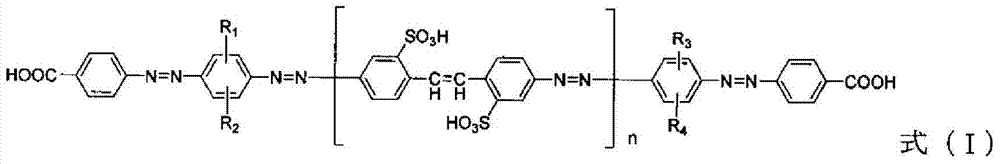

[0053] [Chem 3]

[0054]

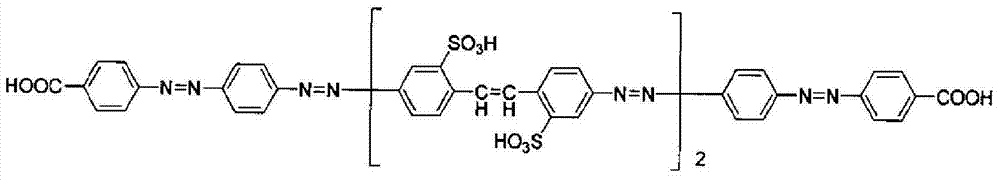

[0055] [Compound Example 2]

[0056] [chemical 4]

[0057]

[0058] [Compound Example 3]

[0059] [chemical 5]

[0060]

[0061] [Compound Example 4]

[0062] [chemical 6]

[0063]

[0064] [Compound Example 5]

[0065] [chemical 7]

[0066]

[0067] The azo compound used as a pigment in the present invention can generally be synthesized according to a known azo dye synthesis method in the technical field (for example, "Dye Chemistry"; Toyo Hosoda; Gihodo; page 626). Diazotization, coupling to manufacture.

[0068] As a representative production method, 4-aminobenzoic acid is diazotized, and it is coupled with anilines represented by the following formula (where R 1 and R 2 represents the same meaning as in the case of the above-mentioned formula (I), and a monoazoamino compound of the following formula is obtained.

[0069] [chemical 8]

[0070]

[0071] [chemical 9]

[0072]

[0073] Next, after reacting the monoazo...

Embodiment 1

[0109] [Example 1] A polyvinyl alcohol-based resin film (VF series manufactured by KURARAY Corporation) with a film thickness of 40 μm, a degree of polymerization of 5500, and a degree of swelling of 232% with a degree of saponification of 99% or more was immersed in warm water at 30°C for 3 Minutes for swelling. The membrane after the swelling treatment was immersed in a 35° C. aqueous solution containing 0.3% by weight of the dye of Compound Example 1, 0.1% by weight of sodium tripolyphosphate, and 0.1% by weight of Glauber’s salt to adsorb the dye. The dye-adsorbed membrane was washed with water, and after washing, boric acid treatment was performed for 1 minute with a 20° C. aqueous solution containing 2% by weight of boric acid. The film obtained by the boric acid treatment was stretched 5.0 times, and was treated in an aqueous solution at 58° C. containing 3.0% by weight of boric acid for 5 minutes. The film obtained by this boric acid treatment was treated with water a...

Embodiment 2

[0113] Except that Compound Example 2 was used instead of Compound Example 1 used in Example 1, samples were prepared in the same manner to prepare measurement samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com