Novel environment-friendly oncomelania killing granule capable of being sprayed and preparation method thereof

A technology for granules and snail killing, which is applied in the field of pesticides to achieve the effects of no dust pollution, avoidance of dust pollution, and no dust drift pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

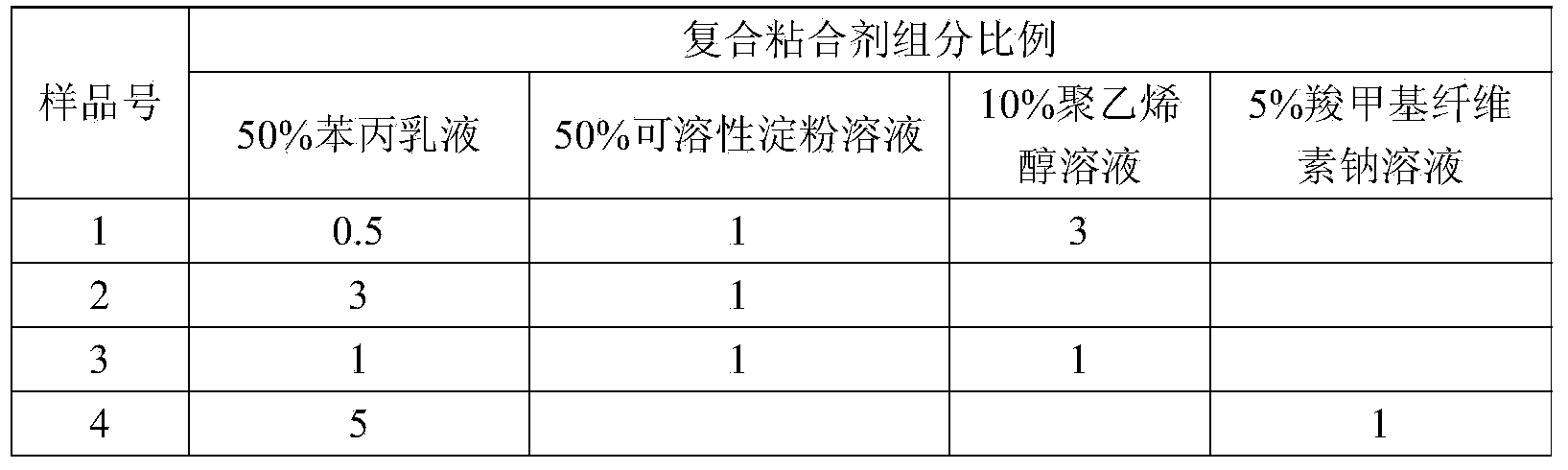

[0024] Embodiment 1: Determination of different binders of 5% spiroxamine ethanolamine salt granules

[0025] The content of each component (by weight) is 5 parts of spiroxamine ethanolamine salt, 3 parts of dispersant polyvinylpyrrolidone, 0.3 part of wetting agent N-oleoyl-N-methyl taurate sodium, diluent white carbon 2 parts of black, after mixing, it is pulverized by a jet mill to obtain a wettable powder with high content and good dispersibility, and then combined with 2 parts of special composite binder (see Table 1 for the composition of the composite binder and corresponding products), the selected sand The base material Jiangsha (60-80 mesh fineness, make up 100 parts), mixed evenly in a wet mixer, and dried in a rotary tunnel kiln to obtain a finished granule. Samples 1-4 were respectively obtained according to the above method.

[0026] Table 1. Composite adhesive components and ratio

[0027]

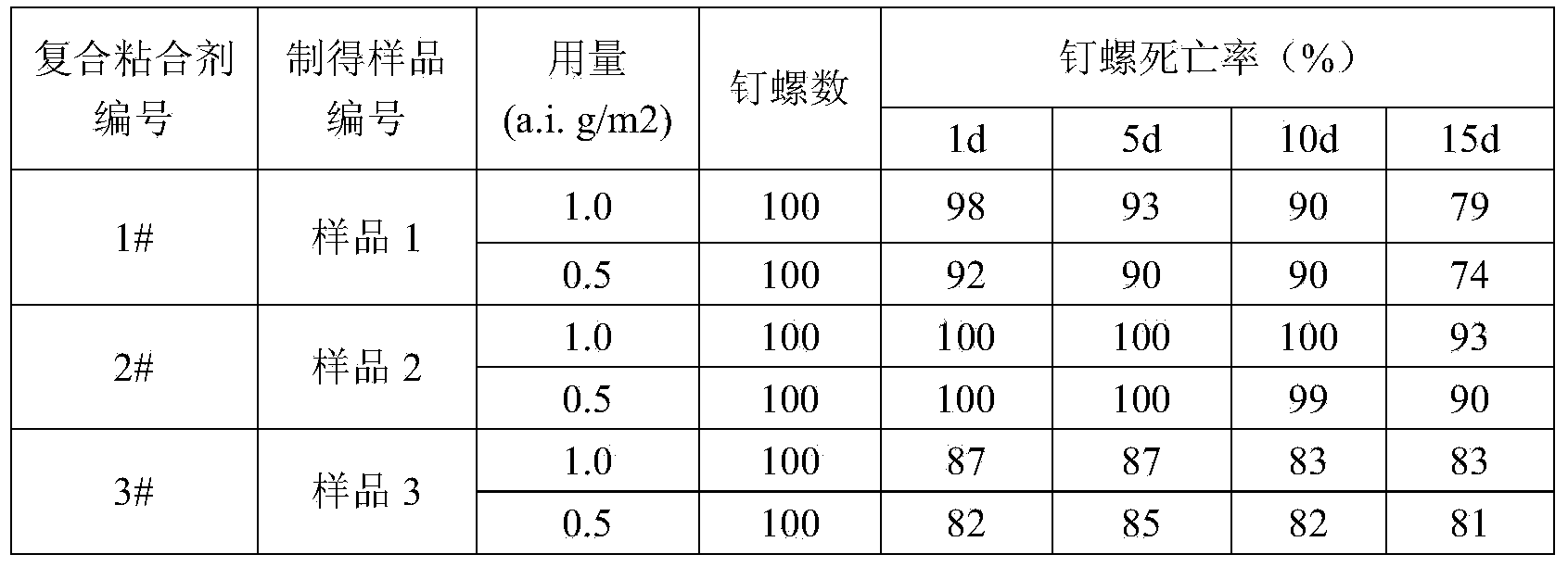

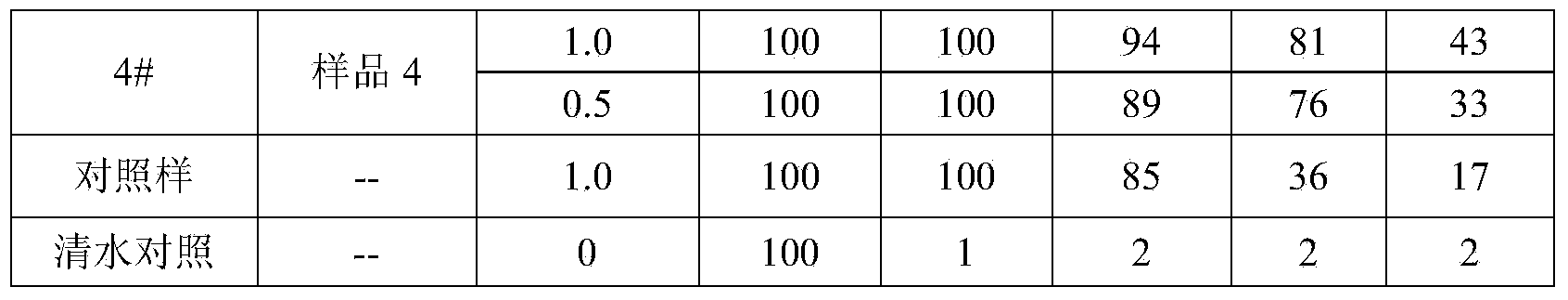

[0028] The above-mentioned samples were tested for indoor control ...

Embodiment 2

[0033] Embodiment 2: 5% spiroxamine ethanolamine salt granules

[0034] The content of each component (by weight) is 5 parts of spiroxamine ethanolamine salt, 3 parts of dispersant polyvinylpyrrolidone, 0.3 part of wetting agent sodium butyl naphthalene sulfonate, 2 parts of white carbon black, 2# composite adhesive 2 parts (see Example 1 for the composition of the composite adhesive), make up to 100 parts of Jiangsha (60-80 mesh fineness), and use the same process as Example 1 to make a finished product.

Embodiment 3

[0037] Embodiment 3: 10% spiroxamine ethanolamine salt granules

[0038] The content of each component (by weight) is 10 parts of spiroxamine ethanolamine salt, 3% of dispersant polyvinylpyrrolidone, 0.5 part of wetting agent fatty alcohol polyoxyethylene, 2 parts of white carbon black, 2# composite adhesive 2 parts (see Example 1 for the composition of the composite adhesive), make up to 100 parts of river sand (fineness 60-80 mesh), and use the same process as in Example 1 to make a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com