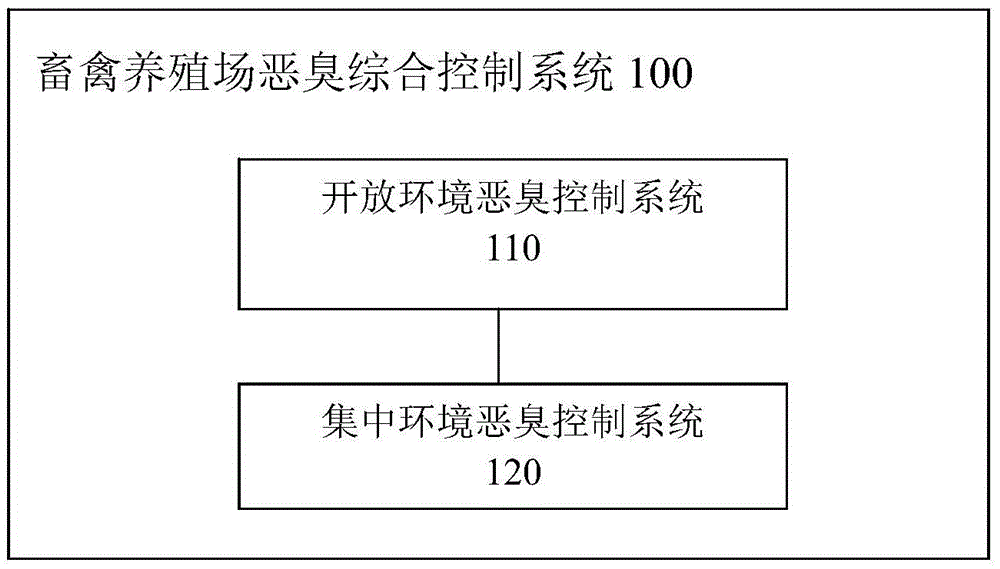

A system and method for comprehensive control of odor in livestock and poultry farms

A technology of comprehensive control and control system, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of limited effect, no comprehensive deodorization control in farms, and single deodorization method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

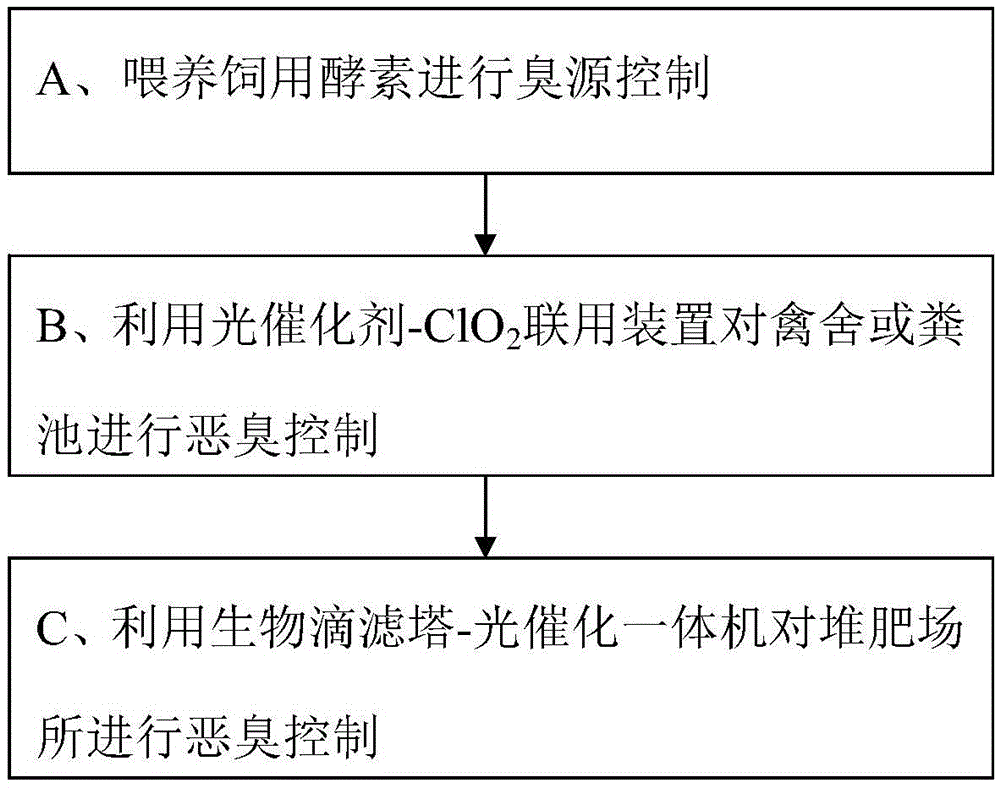

[0033] Most of the livestock and poultry animals (such as pigs, cattle, sheep, chickens, etc.) in livestock farms are raised in captivity by feeding them in an open environment (such as poultry houses). Among them, there must be new agents in the growth process of livestock and poultry animals, and people need to dispose of livestock and poultry excrement in time to ensure the environmental sanitation of the farm and obtain certain economic benefits. The treatment of livestock and poultry excrement generally goes through the following process: first remove the livestock and poultry excrement from the poultry house and move it to the manure tank for processing; and then send the treated solids in the manure tank to the composting site for subsequent processing. In this way, there are at least three sources of odor in livestock and poultry farms: the odor of livestock and poultry animal excrement, the odor of poultry houses and / or manure tanks, and the odor of composting sites. A...

Embodiment 2

[0048] A. Odor source control: 100 weaned young pigs were randomly divided into 2 groups (control group, experimental group) and fed continuously for 30 days; the experimental group was fed pig feed supplemented with 0.01% (w / w) feed enzyme; control group Feed pig feed without adding feed enzymes. Compared with the control group, the experimental group's feed conversion rate increased by 3.5%, daily gain was 5.1%, and the incidence rate was reduced by 20%. Through sensory evaluation, the main odor components were significantly improved.

[0049] B. Odor control in open environment:

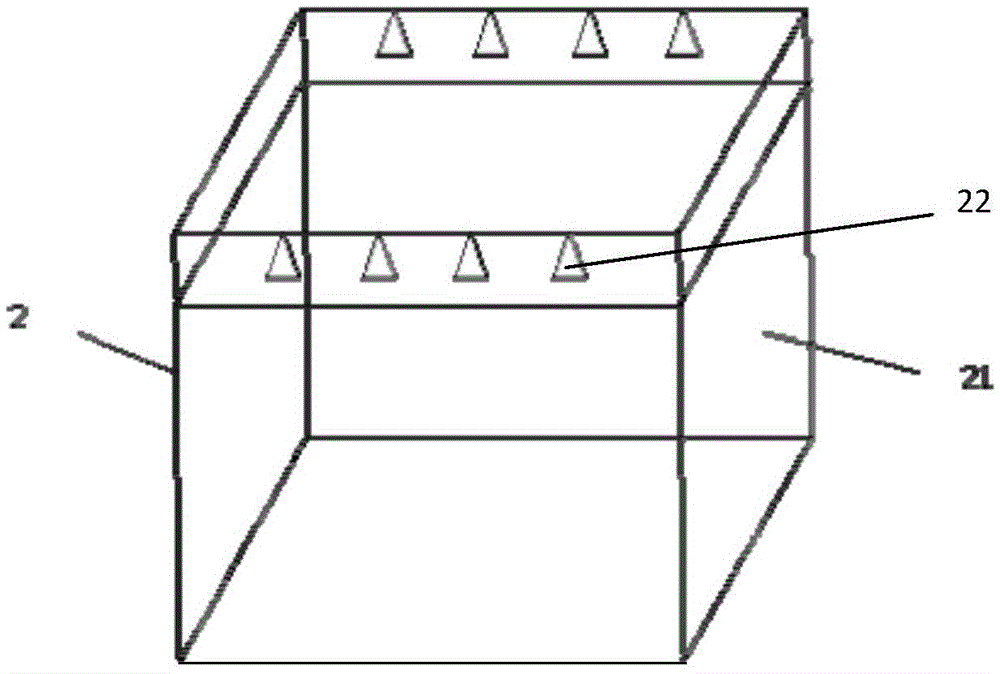

[0050] Combine Figure 4 Shown, photocatalyst-ClO 2 The combined device 2 may also include a thermometer and hygrometer 26 for detecting the temperature and humidity in the open environment and feeding back the detection result to the spray electric control box 25. More preferably, the catalyst -ClO 2 The combined device 2 is provided with a filter 27 between the water pump 23 and the water tank 24 fo...

Embodiment 3

[0056] A. Odor source control: 100 weaned young pigs were randomly divided into 2 groups (control group, experimental group), and fed continuously for 30 days; the experimental group was fed pig feed supplemented with 0.04% (w / w) feed enzyme; control group Feed pig feed without adding feed enzymes. Compared with the control group, the experimental group's feed conversion rate increased by 5.7%, daily weight gain was 11.09%, and the disease rate decreased by 29%. Through sensory evaluation, the main odor components were significantly improved.

[0057] B. Odor control in open environment:

[0058] The dust screen is coated with CT catalyst (30g / m 2 ) And nano iron oxide (20g / m 2 ) The composition of the combined catalyst, the pig house temperature is 22-28 ℃. Spray disinfection of the pig house every 36 hours, ClO 2 (Chlorine dioxide) The concentration is 100ppm, 60 minutes each time. After 12 days of testing, the stench of the experimental pig house has been greatly improved. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com