Method for purifying tail gas of diesel engine through plasmas

A technology of plasma and plasma source, applied in the field of plasma purification of diesel engine exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

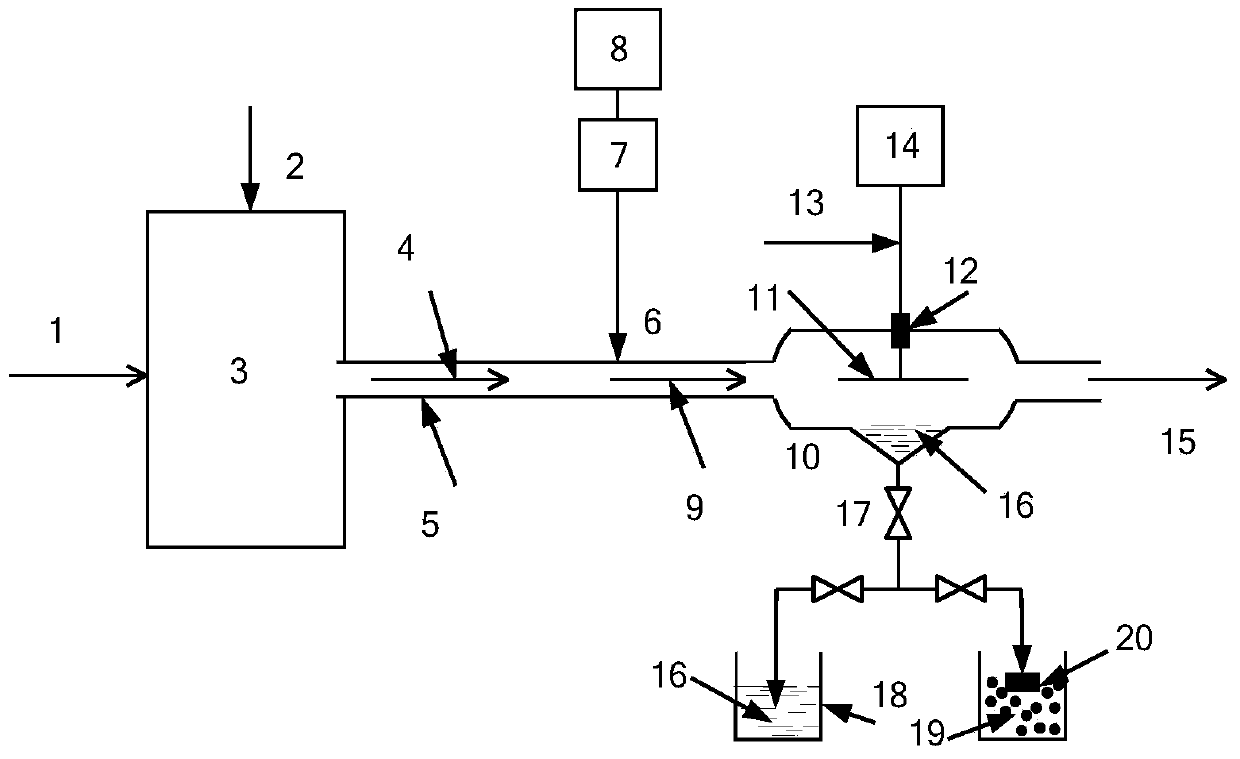

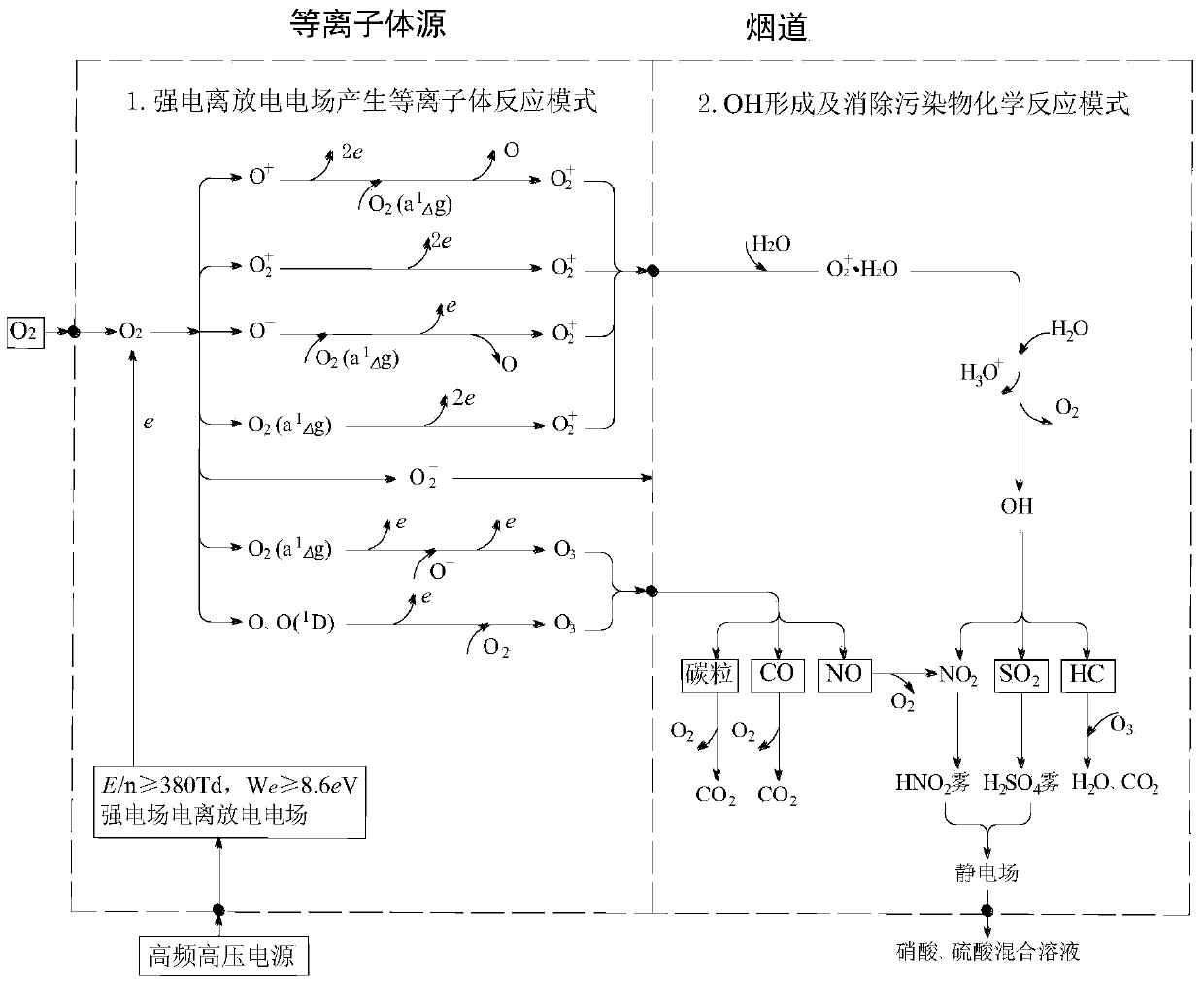

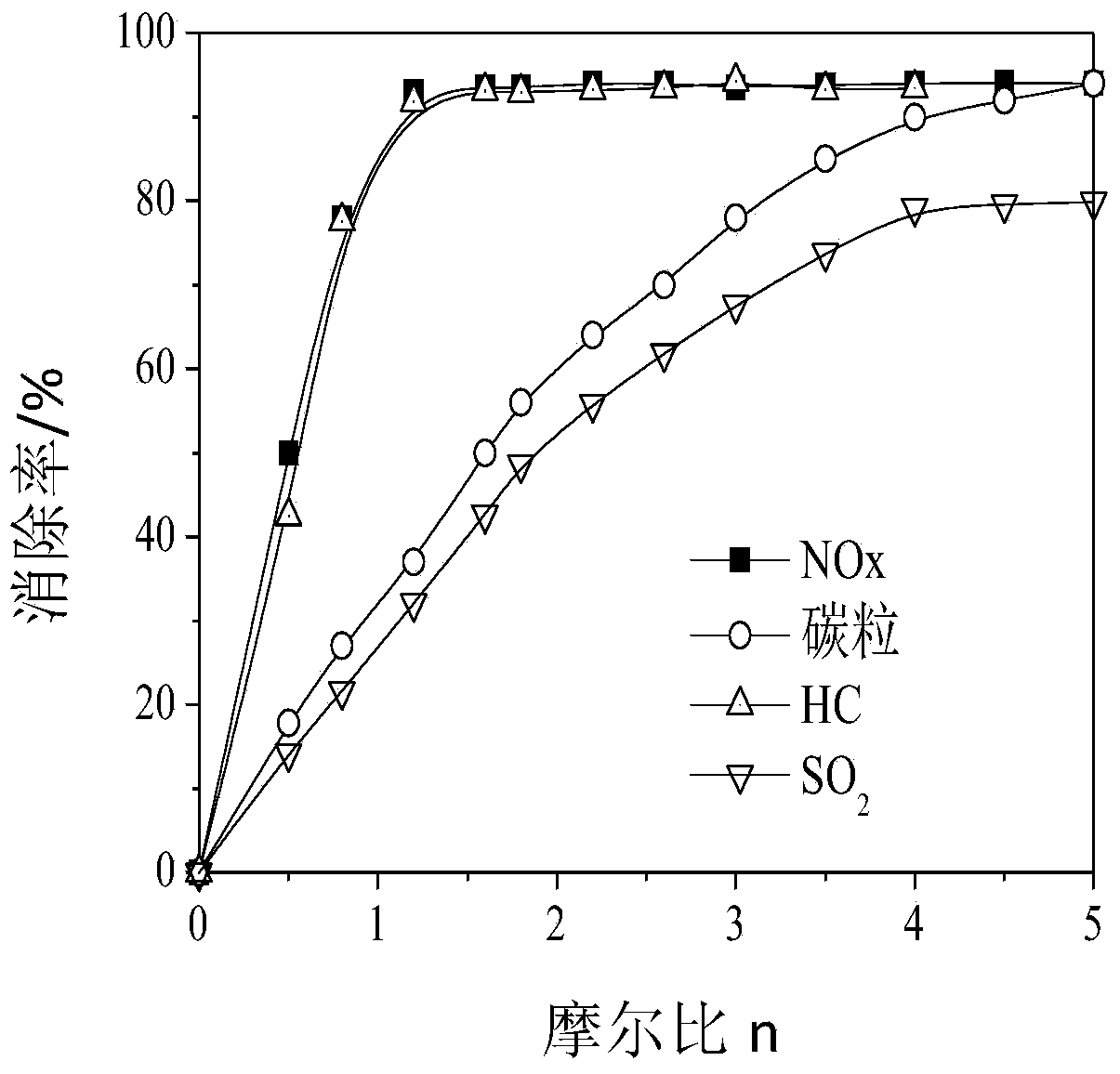

[0043] The present invention adopts a narrow-gap dielectric barrier strong ionization discharge method to construct the plasma source 7, and the high-frequency high-voltage power supply 8 provides high-frequency high-voltage to the plasma source, and a strong electric field with a reduced electric field strength of 300Td to 500Td is formed in the discharge gap in the plasma source. ionization electric field, O 2 After being dissociated by a strong ionizing discharge electric field, a plasma with a concentration of 80mg / L to 400mg / L is formed after ionization (O 2 + , O 2 - , O 2 (a 1 Δ g ), O 3 Wait). General embodiment of the present invention is as figure 1 shown. First inject the plasma 6 into the exhaust pipe 5 of the diesel engine 3, and the plasma 6 will oxidize the soot particles into CO 2 and H 2 O; at the same time in the exhaust pipe 5 to contain NOx, SO 2 , HC and carbon particles in diesel engine exhaust 4 are oxidized to NO 2 , O 3 Oxidize CO to CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com