Preparation method, product and application of carbon-supported activated mnox

A carbon-supported and active technology, which is applied in the field of preparation of carbon-supported active MnOx, can solve problems such as difficult preparation of supported catalysts, and achieve the effects of maintaining degradation effect, strong stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 3g of activated carbon to manganese sulfate solution (100ml, 0.2mol / L) with a molar mass of 0.02mol, stir at room temperature for 20min, mix well and let stand for 12h, then add equimolar ammonium persulfate solution (200ml, 0.1mol / L) / L), stirred and mixed at room temperature, then carried out hydrothermal reaction, the temperature was 120°C, and the time was 12h. After the hydrothermal reaction, it was naturally cooled to room temperature, centrifuged, the solid was washed with water, and finally dried to obtain carbon-supported active MnOx, where x is generally Between 3 and 4, the following examples are the same.

[0034] The carbon-supported active MnO prepared in the present embodiment is tested for performance respectively, and the test results are as follows: figure 1 , figure 2 and image 3 Shown:

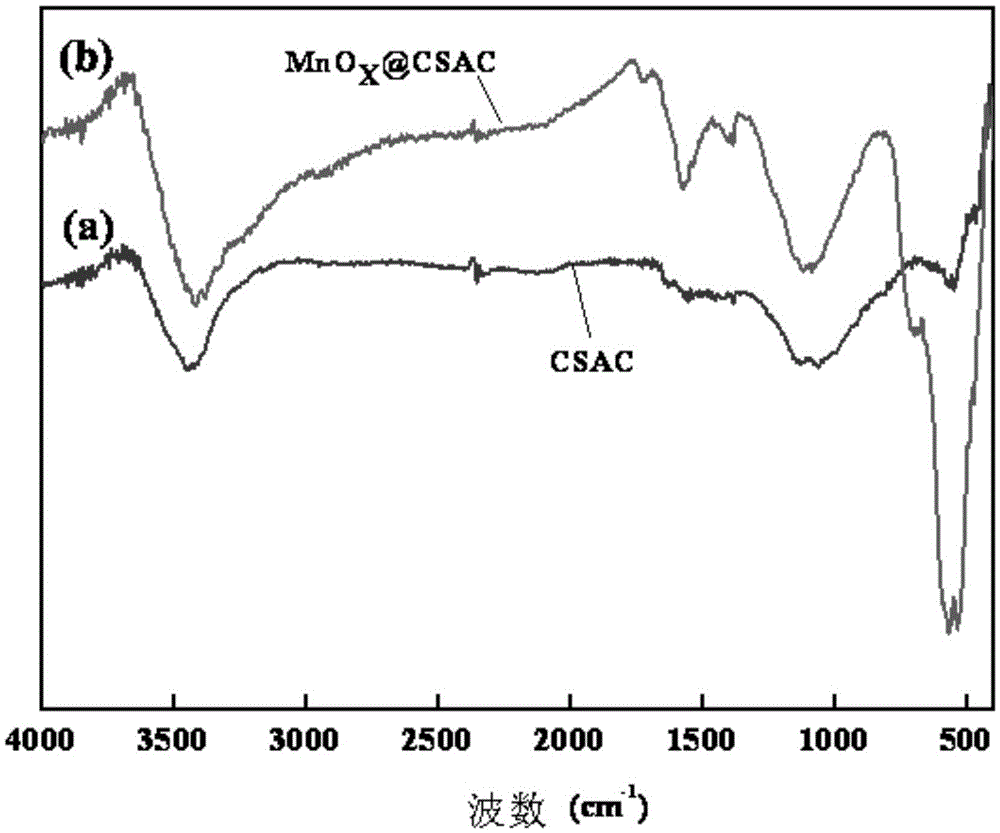

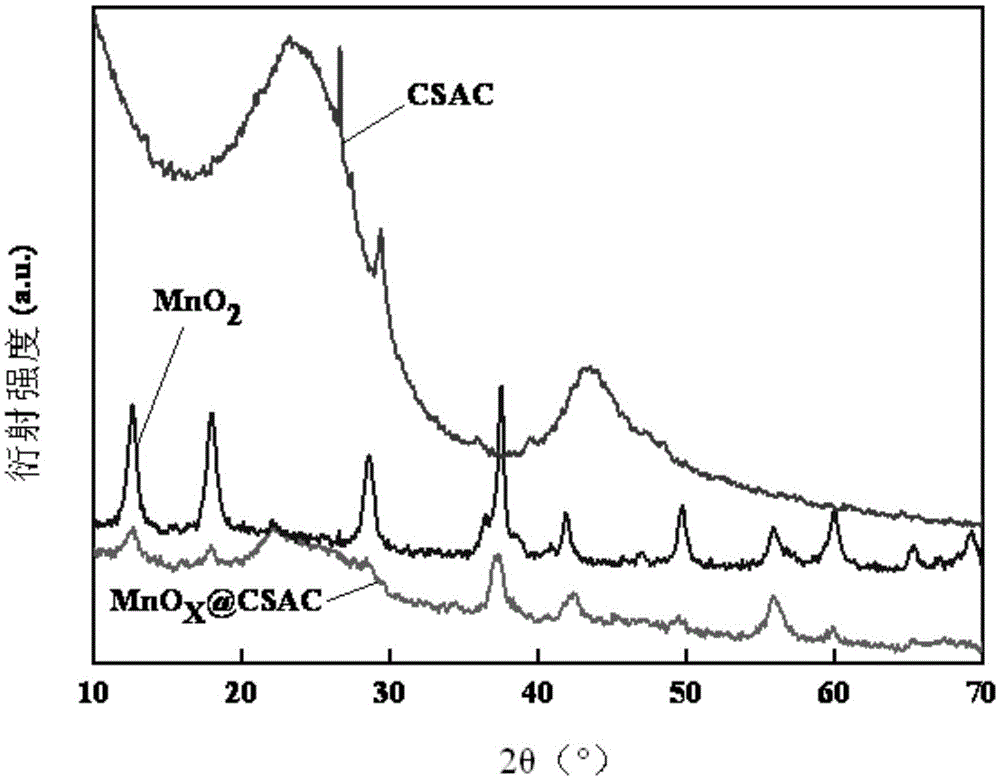

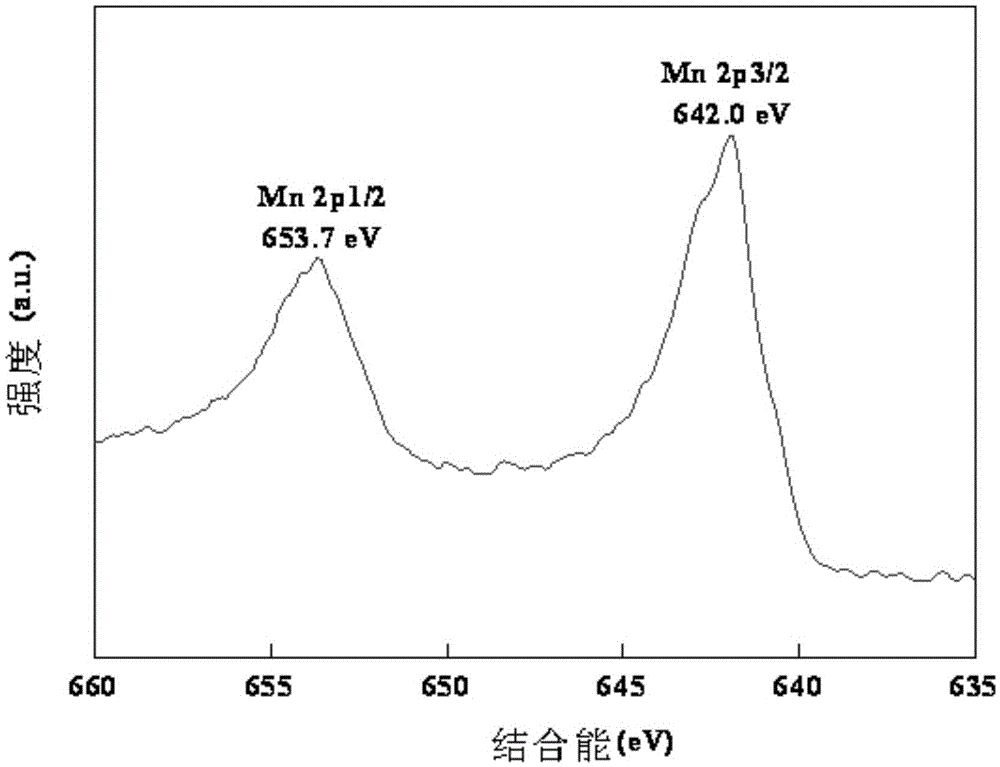

[0035] figure 1 It is a Fourier transform infrared spectrogram, and the changes of functional groups on the surface of activated carbon before and after lo...

Embodiment 2

[0039] Add 3g of activated carbon to manganese sulfate solution (100ml, 0.4mol / L) with a molar mass of 0.04mol, stir at room temperature for 20min, mix well and let stand for 12h, then add equimolar ammonium persulfate solution (200ml, 0.2mol / L), stirred and mixed at room temperature, then carried out hydrothermal reaction at 120°C for 12 hours, cooled naturally to room temperature after hydrothermal reaction, centrifuged, washed the solid with water, and finally dried to obtain carbon-supported active MnOx.

Embodiment 3

[0041] Add 3g of activated carbon to manganese sulfate solution (100ml, 0.2mol / L) with a molar mass of 0.02mol, stir at room temperature for 20min, mix well and let stand for 12h, then add equimolar ammonium persulfate solution (200ml, 0.1mol / L) / L), stirred and mixed at room temperature, and carried out hydrothermal reaction at 140°C for 12 hours. After hydrothermal reaction, it was naturally cooled to room temperature, centrifuged, the solid was washed with water, and finally dried to obtain carbon-supported active MnOx.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com