Method for cleaning nylon 6 polymerization and recovery system filler tower

The technology of a recovery system and a packed tower is applied in the field of caprolactam monomer recovery process, which can solve the problems of troublesome packing disassembly and cleaning, waste of monomers, easy blockage of packings, etc., so as to be beneficial to environmental protection, reduce the loss of monomers, and reduce the consumption of monomers. body mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

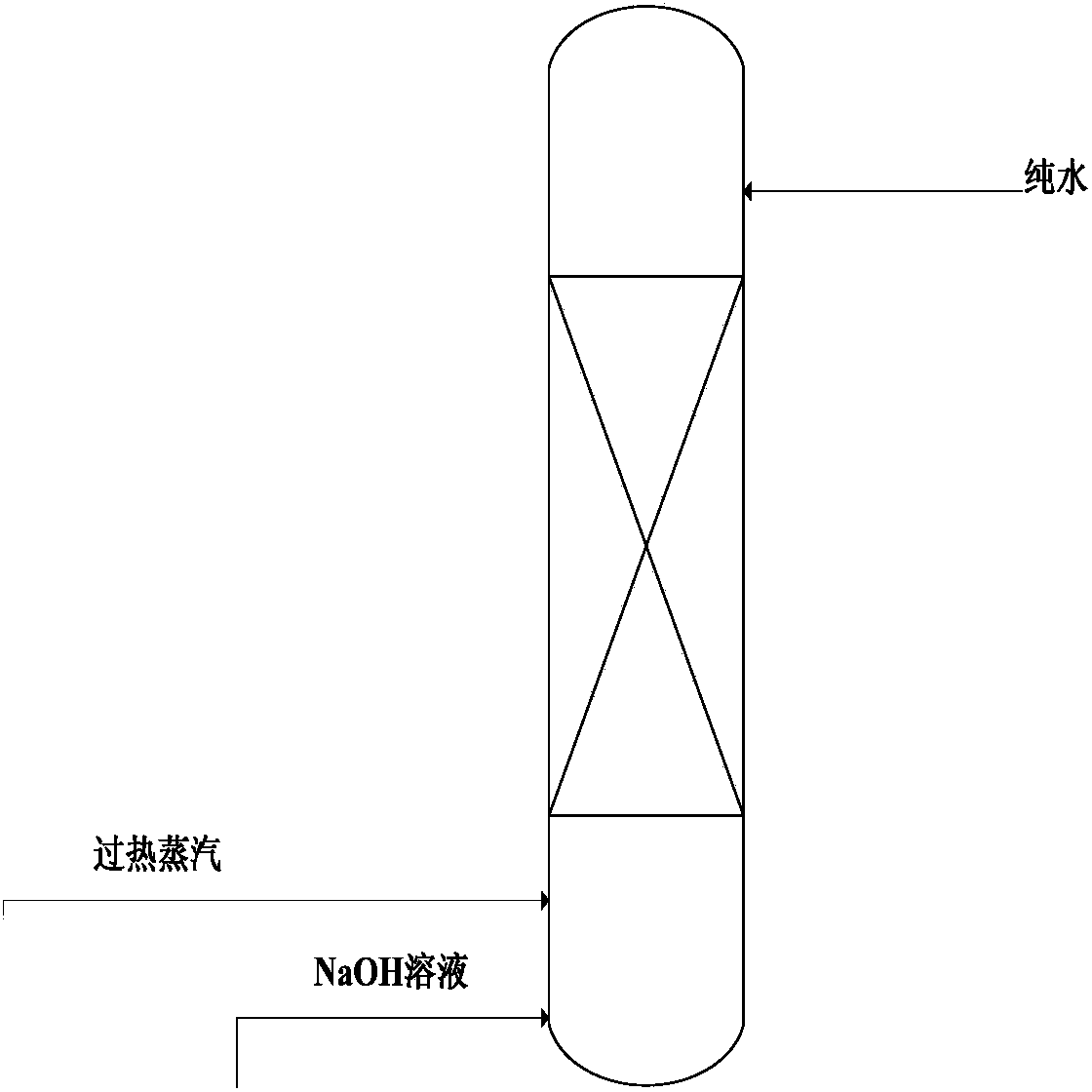

[0020] 1) Pass superheated steam into the lower part of the packed tower;

[0021] 2) Pass pure water into the upper part of the packed tower;

[0022] 3) The superheated steam rises into the packing and contacts the residue adhered to the packing, and the residue is heated and eluted by pure water, and falls to the bottom of the packing tower, thereby being removed;

[0023] 4) The NaOH solution with a mass percentage concentration of 0.1% is passed into the bottom of the packed tower, and under the action of superheated steam, the cleaning process of the packing can be accelerated.

Embodiment 2

[0025] 1) Pass superheated steam into the lower part of the packed tower;

[0026] 2) Pass pure water into the upper part of the packed tower;

[0027] 3) The superheated steam rises into the packing and contacts the residue adhered to the packing, and the residue is heated and eluted by pure water, and falls to the bottom of the packing tower, thereby being removed;

[0028] 4) The NaOH solution with a mass percentage concentration of 0.2% is passed into the bottom of the packed tower, and under the action of superheated steam, the cleaning process of the packing can be accelerated.

Embodiment 3

[0030] 1) Pass superheated steam into the lower part of the packed tower;

[0031] 2) Pass pure water into the upper part of the packed tower;

[0032] 3) The superheated steam rises into the packing and contacts the residue adhered to the packing, and the residue is heated and eluted by pure water, and falls to the bottom of the packing tower, thereby being removed;

[0033] 4) The NaOH solution with a mass percentage concentration of 1% is passed into the bottom of the packed tower, and under the action of superheated steam, the cleaning process of the packing can be accelerated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com