Base material containing fresh semi-hydrated ardealite, quick lime and coal ash for pavement

A technology of pavement base material and hemihydrate phosphogypsum is applied in the field of road materials to achieve the effect of reducing costs and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

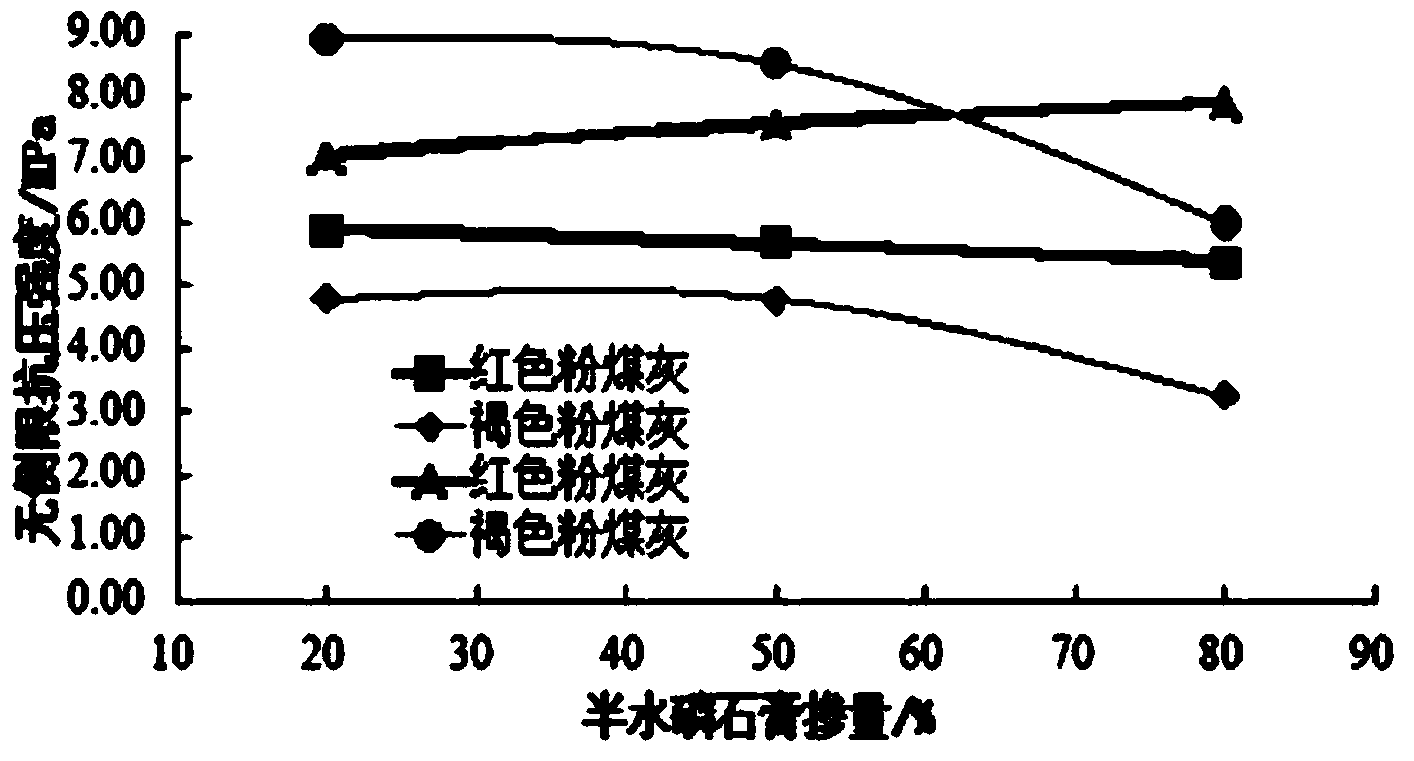

[0042] Fresh phosphogypsum hemihydrate-quicklime-red fly ash system pavement base: weigh hemihydrate phosphogypsum, quicklime, and red fly ash according to the design components in Table 1, and conduct a compaction test to determine the best mixture. Moisture content and maximum dry density, according to the controlled degree of compaction to form the test piece and measure its unconfined compressive strength, according to the degree of compaction of 95% to conduct the unconfined compressive strength test, the 7d (6d for health, 1d for immersion) ) The specific results of unconfined compressive strength are shown in Table 1.

[0043] Table 1 Performance indicators of phosphogypsum hemihydrate fly ash (red fly ash) pavement base

[0044]

[0045] From the performance indicators in Table 1, it can be seen that when the dosage of phosphogypsum hemihydrate is changed, its strength increases first and then decreases with the increase of the dosage of phosphogypsum hemihydrate. W...

Embodiment 2

[0047] Hemihydrate phosphogypsum-quicklime-brown fly ash system pavement base: Weigh hemihydrate phosphogypsum, quicklime, and brown fly ash according to the design components in Table 2, and conduct a compaction test to determine the optimum water content of the mixture Ratio and maximum dry density, according to the controlled degree of compaction molding test pieces and determine its unconfined compressive strength. The particle size of brown fly ash is less than or equal to 0.6mm. Change the dosage of phosphogypsum hemihydrate, and carry out the unconfined compressive strength test according to the compaction degree of 95%. The specific results of compressive strength are shown in Table 2.

[0048] Table 2 Performance indicators of phosphogypsum hemihydrate fly ash (brown fly ash) pavement base

[0049]

[0050] From the performance indicators in Table 2, it can be seen that when the content of phosphogypsum hemihydrate is changed, its strength shows a decreasing trend...

Embodiment 3

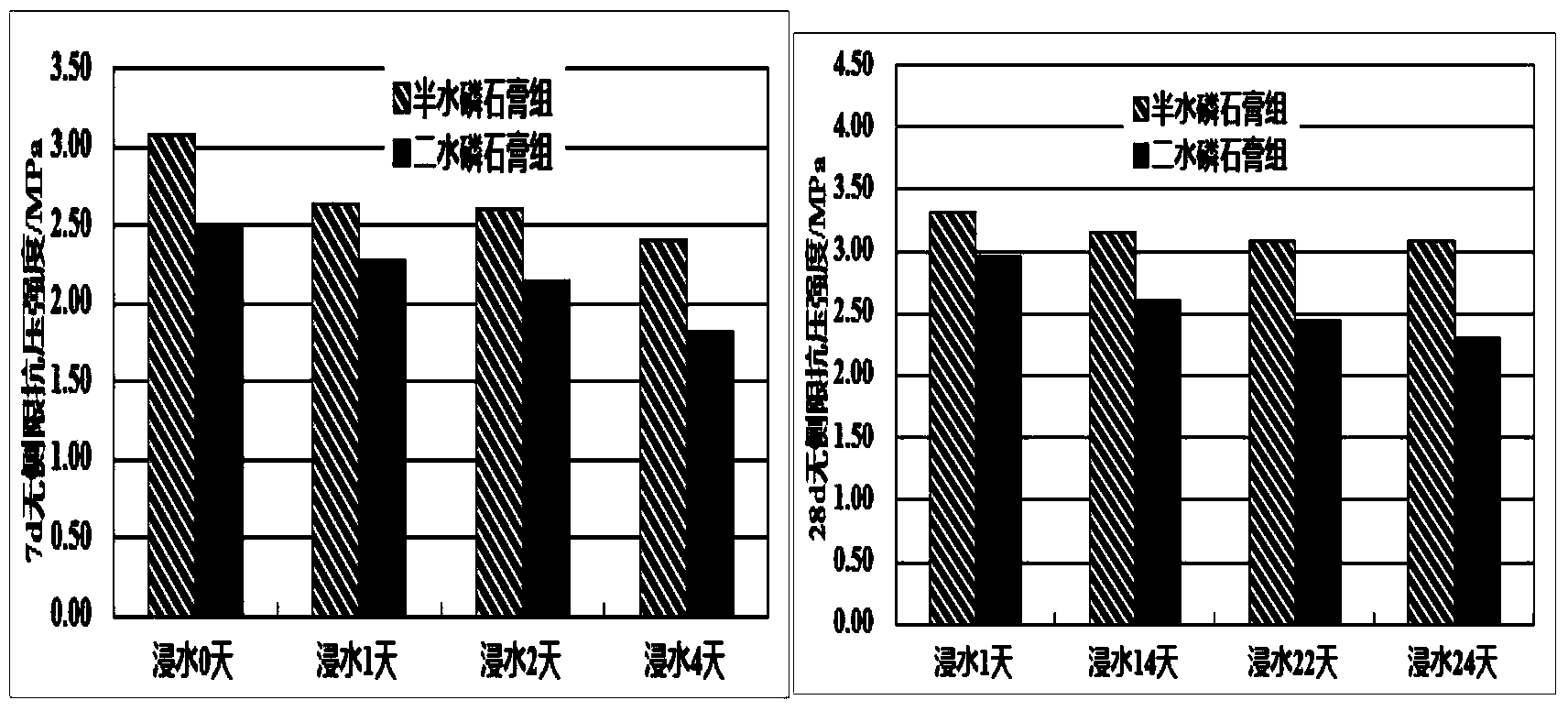

[0052] Water stability of phosphogypsum hemihydrate lime ash pavement base: in order to consume hemihydrate phosphogypsum to the greatest extent, on the basis of the research of embodiment 1 and embodiment 2, the consumption of hemihydrate phosphogypsum is the largest and meets the requirements of pavement base The composition design is used to test the water stability performance; the test pieces are formed according to the compaction degree of 95%, and the water stability tests are carried out for 7d and 28d respectively. The test results are shown in Table 3 and figure 2 .

[0053] Table 3 Water stability of phosphogypsum fly ash (red fly ash) pavement base

[0054]

[0055] From Table 3 and figure 2 It can be seen that with the extension of water soaking time, the strength of hemihydrate phosphogypsum-fly ash base layer decreases, and its strength loss rate is 28% compared with the base layer without water soaking for 4 days after wet curing for 3 days, and compared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com