Production method of benfotiamine

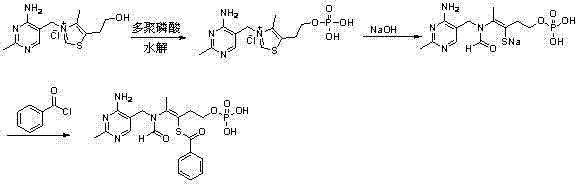

A technology of benfotiamine and its production method, which is applied in the fields of chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the difficulty of direct precipitation of vitamin B1 phosphate monoester products and the potential safety hazards , Inconvenient hydrolysis operation, etc., to achieve the effect of reducing solvent consumption, reducing production costs, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] After adding 4000kg polyphosphoric acid into the reaction kettle, raise the temperature to 100-120°C, add 1000kg of vitamin B1 to the reaction kettle in batches, keep it in this temperature range for 8 hours after adding, add 3000kg of water to quench After the reaction, heat up to 80-90°C for 10 hours of hydrolysis; cool down to room temperature, add 5000kg of trioctylamine / methyl tert-butyl ether = 1 / 1 mixture to extract phosphoric acid; add 5000kg of methanol to the water phase Precipitate solids and centrifuge to obtain 1200kg of crude vitamin B1 phosphate monoester; mix 1200kg of vitamin B1 phosphate monoester crude with 6000kg of water for beating, cool down to 0-5°C, and add liquid alkali dropwise within this temperature range to adjust the pH value of the system to 12.0 to 14.0; after pH adjustment, ensure that the temperature in the reactor is 10 to 25°C and add 1200kg of benzoyl chloride dropwise. After the addition is completed, keep warm until the reaction is...

Embodiment 2

[0029] After adding 5000kg of polyphosphoric acid into the reaction kettle, raise the temperature to 80-100°C, add 1000kg of vitamin B1 to the reaction kettle in batches, keep it in this temperature range for 6 hours after adding, add 5000kg of water to quench After the reaction, heat up to reflux and hydrolyze for 5 hours; drop to room temperature, add 4000kg of trioctylamine / methyl tert-butyl ether=1 / 1 mixed solution to extract twice; add 6000kg of ethanol to the water phase to precipitate solids , centrifuged to obtain 1200kg of crude vitamin B1 phosphate monoester; after mixing 1200kg of vitamin B1 phosphate monoester crude product with 6000kg of water for beating, the temperature was lowered to 0-5°C, and liquid alkali was added dropwise within this temperature range to adjust the pH value of the system to 10.0 ~12.0; After pH adjustment, ensure that the temperature in the reactor is 10-25°C, add 1200kg of benzoyl chloride dropwise, keep warm until the reaction is complete...

Embodiment 3

[0031] After adding 3000kg of polyphosphoric acid into the reaction kettle, raise the temperature to 90-110°C, add 1000kg of vitamin B1 to the reaction kettle in batches, keep it in this temperature range for 5 hours after adding, add 5000kg of water to quench After the reaction, heat up to 90-100°C for hydrolysis for 5 hours; cool down to room temperature, add 5000kg of trioctylamine / methyl tert-butyl ether=1 / 1 mixed solution to the kettle for extraction twice; add 7000kg Acetone precipitated solids and centrifuged to obtain 1230kg of crude vitamin B1 phosphate monoester; after mixing 1200kg of vitamin B1 phosphate monoester crude with 6000kg of water for beating, the temperature was lowered to 0-5°C, and liquid alkali was added dropwise within this temperature range to adjust the pH of the system value to 11.0~13.0; after pH adjustment, ensure that the temperature in the reactor is 10~25°C, add 1200kg of benzoyl chloride dropwise, keep warm until the reaction is complete afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com