Flame-retardant wood adhesive as well as preparation method and application thereof

A wood adhesive and flame-retardant technology, applied in the field of formaldehyde-free flame-retardant composite wood, can solve the problems of flame-retardant component migration loss, incomplete chemical reaction, etc., achieve good flame-retardant performance, simple and easy operation, and process operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

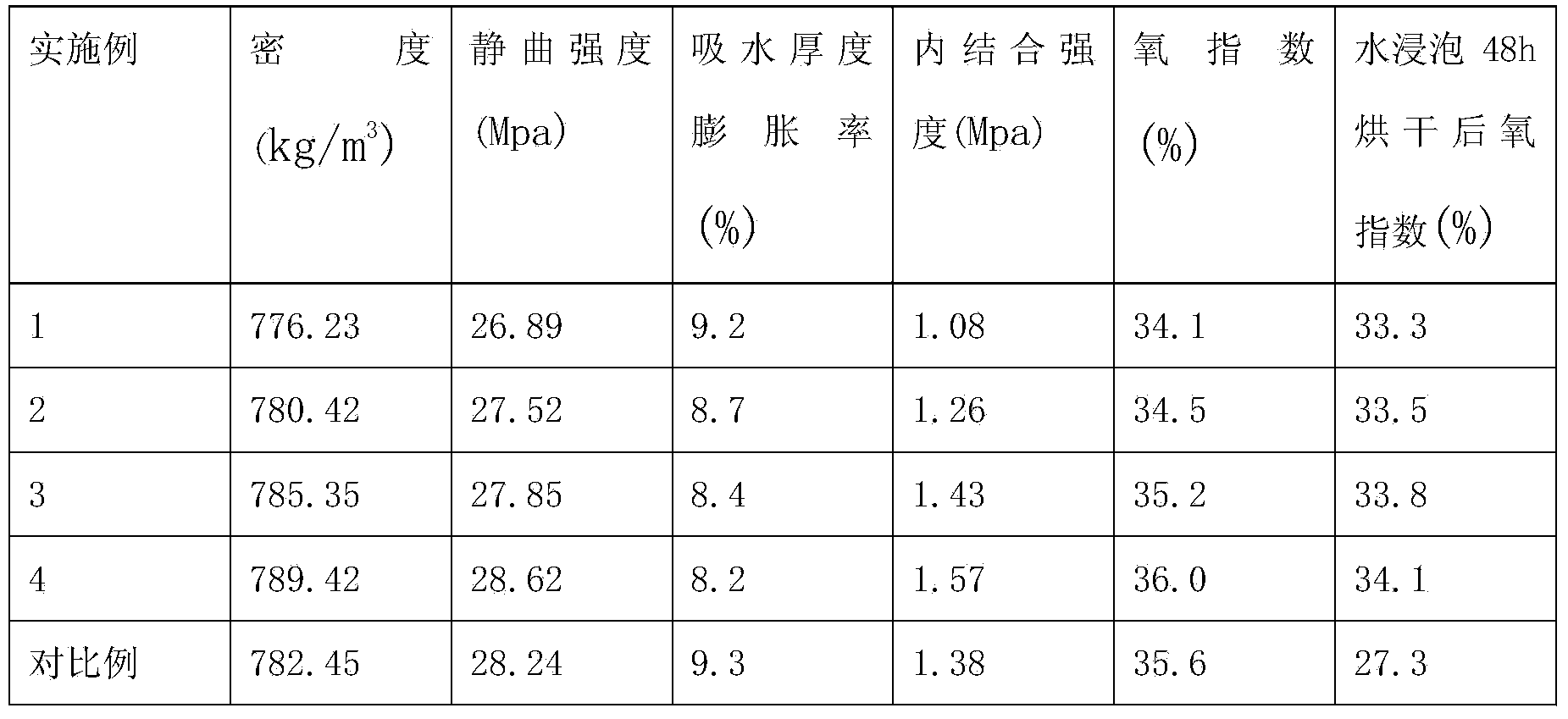

Examples

Embodiment 1

[0026] (1) Preparation of melamine phosphogluconate mixed salt flame retardant

[0027] Add phosphoric acid 39.2g (0.4 moles, 1.2 chemical equivalents), gluconic acid 352.8g (1.8 moles, 1.8 chemical equivalents) and deionized water 2352g into a reactor with heating and stirring, at a temperature of 75°C, under stirring Slowly add melamine 126g (1.0 moles, 3.0 chemical equivalents), keep it warm for 6 hours, then cool down to room temperature, let stand for 24 hours, and precipitate mixed salts. After filtering, drying and crushing, the white powdery melamine phosphogluconate mixed salt flame retardant was obtained.

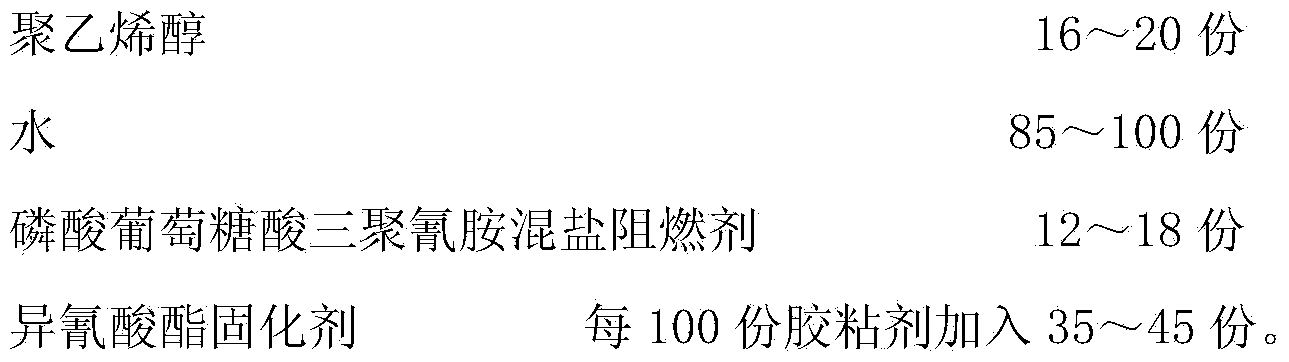

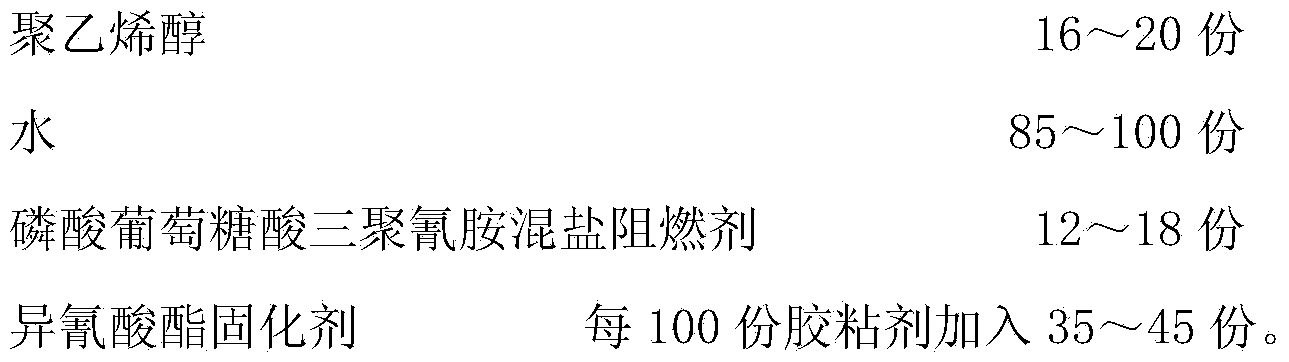

[0028] (2) Preparation of flame retardant wood adhesive

[0029] In a reactor equipped with heating, stirring and temperature control devices, add 85 parts of water, heat to 85°C, add 16 parts of polyvinyl alcohol under stirring, maintain the temperature, and stir until the polyvinyl alcohol is completely dissolved. Then slowly add 12 parts of phosphogluconate m...

Embodiment 2

[0038] (1) Preparation of melamine phosphogluconate mixed salt flame retardant

[0039] Add 58.8g of phosphoric acid (0.6 mol, 1.8 chemical equivalent), 294g of gluconic acid (1.5 mol, 1.5 chemical equivalent), and 1764g of deionized water into the reactor with heating and stirring, at a temperature of 85 ° C, under stirring Slowly add 138.6 g of melamine (1.1 moles, 3.3 chemical equivalents), keep the temperature for 5 hours, then cool down to room temperature, and let it stand for 24 hours to precipitate mixed salts. After filtering, drying and crushing, the white powdery melamine phosphogluconate mixed salt flame retardant was obtained.

[0040] (2) Preparation of flame retardant wood adhesive

[0041] In a reactor equipped with heating, stirring and temperature control devices, add 90 parts of water, heat to 85°C, add 17 parts of polyvinyl alcohol under stirring, maintain the temperature, and stir until the polyvinyl alcohol is completely dissolved. Slowly add 14 parts o...

Embodiment 3

[0050] (1) Preparation of melamine phosphogluconate mixed salt flame retardant

[0051] Add 73.5g of phosphoric acid (0.75 moles, 2.25 chemical equivalents), 235.2g of gluconic acid (1.2 moles, 1.2 chemical equivalents) and 1543.5g of deionized water into a reactor with heating and stirring, at a temperature of 90°C, while stirring Slowly add 144.9 g of melamine (1.15 moles, 3.45 chemical equivalents) under low temperature, keep the temperature for 4 hours, then cool down to room temperature, let it stand for 24 hours, and precipitate mixed salts. After filtering, drying and crushing, the white powdery melamine phosphogluconate mixed salt flame retardant was obtained.

[0052] (2) Preparation of flame retardant wood adhesive

[0053] In a reactor equipped with heating, stirring and temperature control devices, add 95 parts of water, heat to 90°C, add 18 parts of polyvinyl alcohol under stirring, maintain the temperature, and stir until the polyvinyl alcohol is completely diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com