Glass fiber reinforced engineering plastic plate and simple high-damping isolating bearing

A technology of engineering plastics and glass fiber, applied in the field of composite materials, can solve the problems of expensive construction technology, low building layers, and low total investment, and achieve the effects of superior mechanical properties, low cost, and large vertical bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Clean the mold table and apply the release agent on the required work table. Lay a layer of release cloth on the area where the release agent is applied, stack the prepared 5 layers of 04 glass fiber grid cloth on the release cloth in order, and place a guide on the fiber grid cloth Net, except for the side reserved for glue injection, the diversion net in other areas needs to be 30-40mm away from the edge of the glass fiber grid cloth, and then wrap the glass fiber grid cloth and the diversion net with a release cloth.

[0035] Arrange the exhaust pipe and rubber injection pipe at both ends of the release cloth. The air extraction pipe is wrapped and lifted with the release cloth, the rubber injection pipe is wrapped with the release cloth, and the sealant is fixed. The air suction pipe extracts the air in the release cloth to reduce the pressure of the space wrapped by the release cloth to 3MPa~6MPa, and then pour the defoamed epoxy resin into the glass fiber grid clo...

Embodiment 2

[0049] Clean the mold table and apply the release agent on the required work table. Lay a layer of release cloth on the area where the release agent is applied, stack the prepared 5 layers of 04 glass fiber grid cloth on the release cloth in order, and place a guide on the fiber grid cloth Net, except for the side reserved for glue injection, the diversion net in other areas needs to be 30-40mm away from the edge of the glass fiber grid cloth, and then wrap the glass fiber grid cloth and the diversion net with a release cloth.

[0050] Arrange the exhaust pipe and rubber injection pipe at both ends of the release cloth. The air extraction pipe is wrapped and lifted with the release cloth, the rubber injection pipe is wrapped with the release cloth, and the sealant is fixed. The air suction pipe extracts the air in the release cloth to reduce the pressure of the space wrapped by the release cloth to 3MPa~6MPa, and then pour the unsaturated polyester after the defoaming treatmen...

Embodiment 3

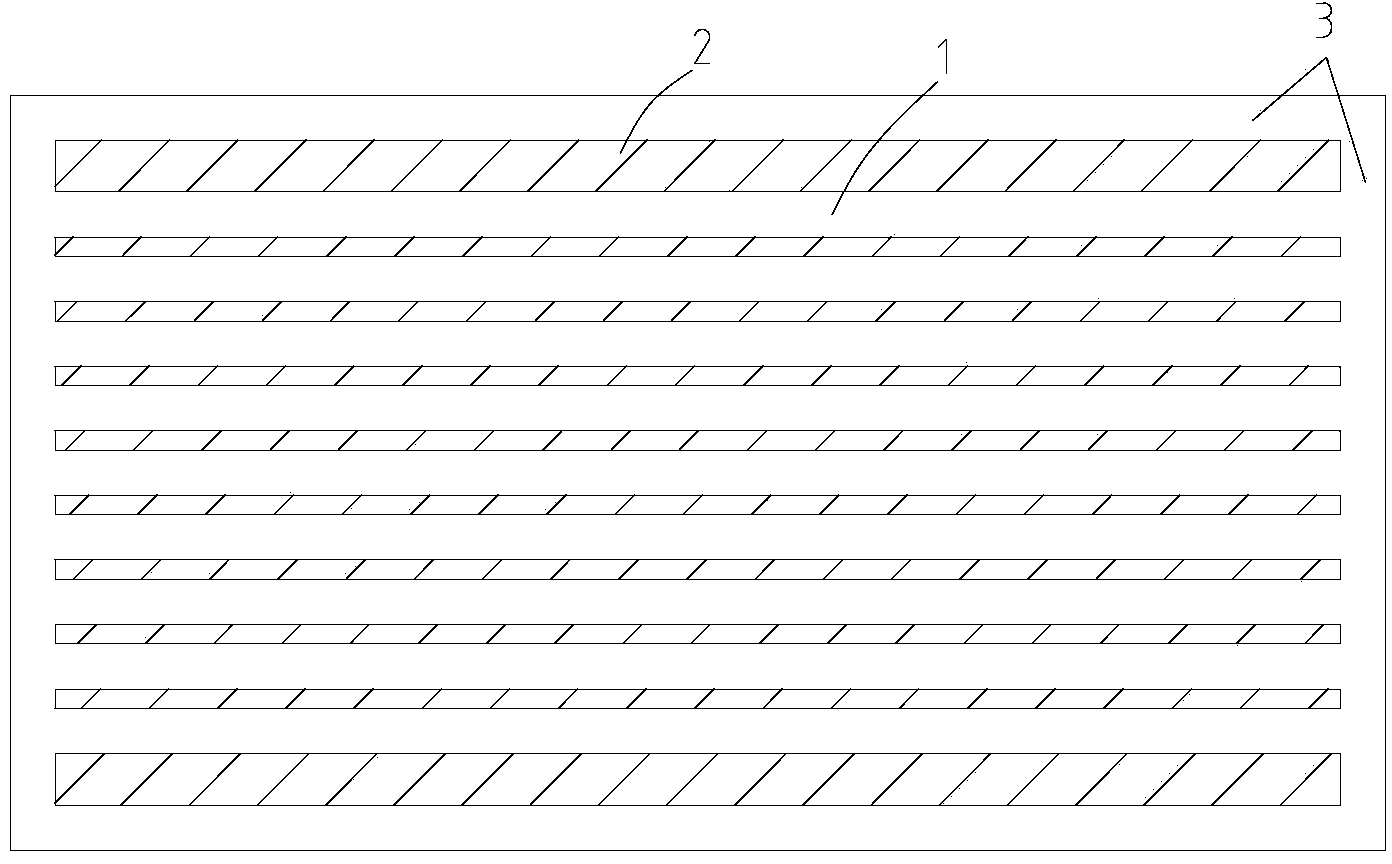

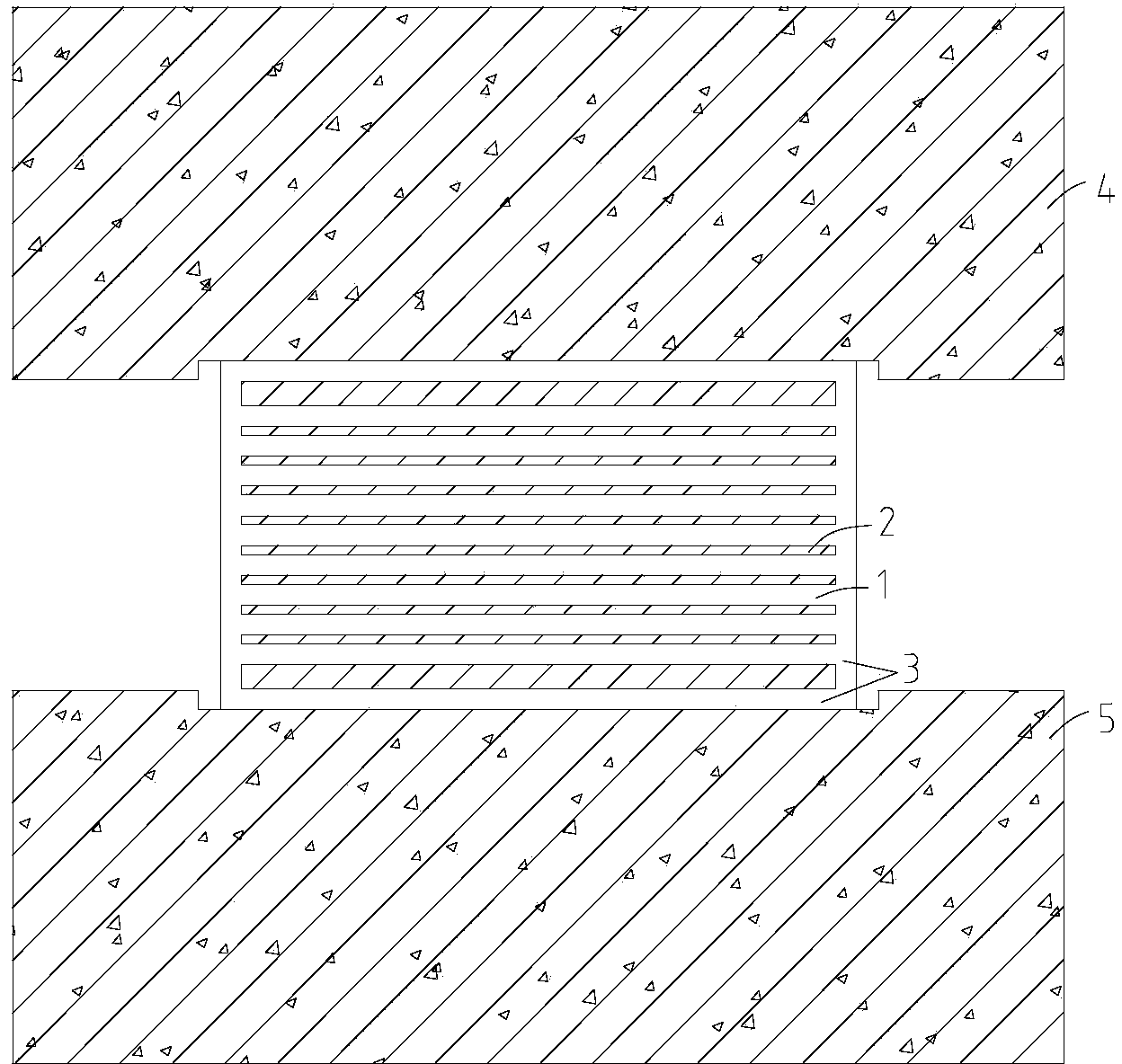

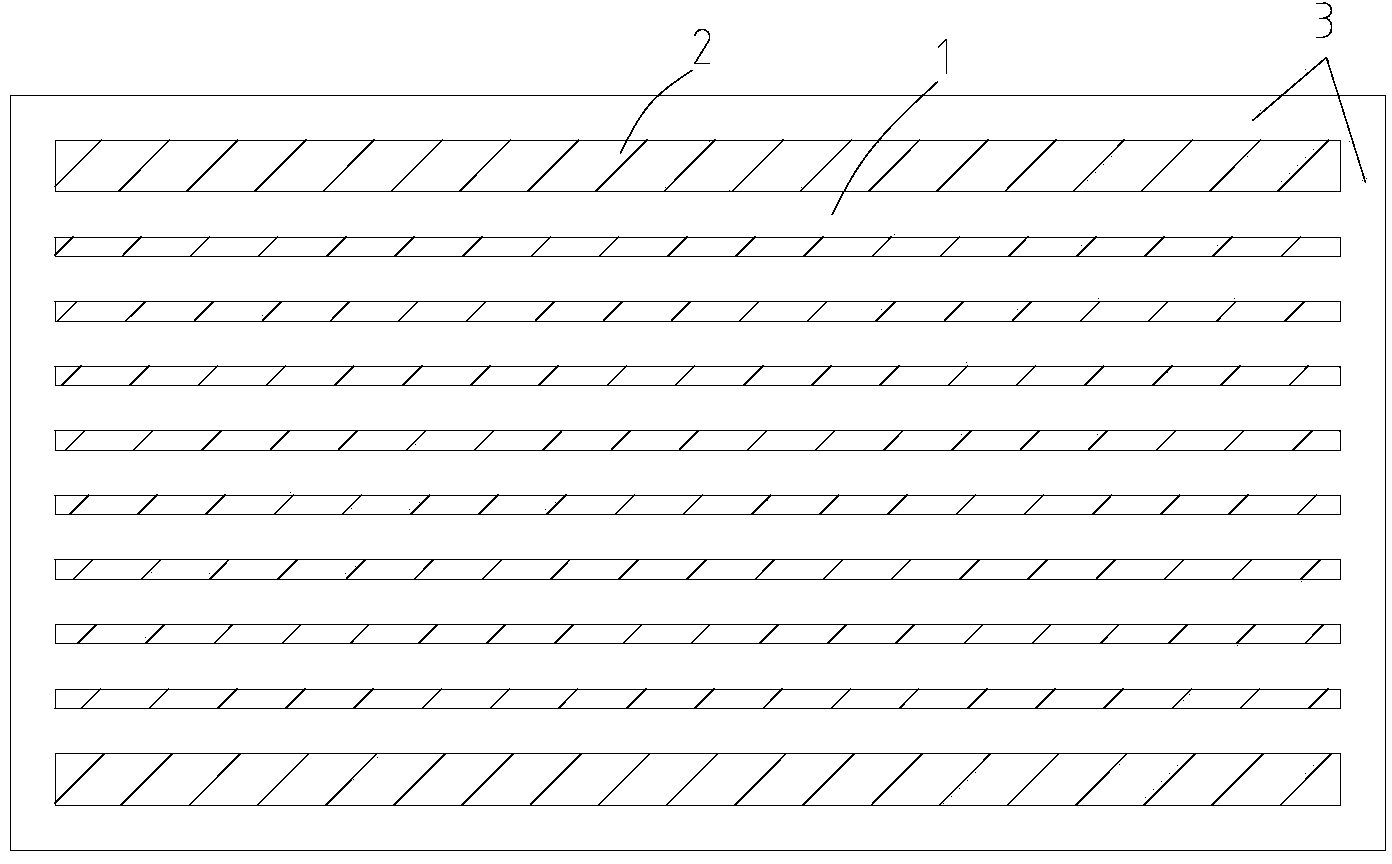

[0064] see figure 1 , the high-damping simple shock-isolation bearing in this embodiment includes a bearing main body; the bearing main body is formed by alternately superimposing and vulcanizing rubber layers 1 and engineering plastic plates 2, and the upper sealing plate is the topmost engineering plastic plate 2, and the lower The sealing plate is the lowest engineering plastic plate 2, and the thickness of the upper sealing plate and the lower sealing plate is greater than that of the engineering plastic plates 2 of other layers. The damping ratio of the rubber layer 1 is 5%-30%. The high-damping simple shock-isolation support also includes a rubber protective layer 3 wrapping the main body of the support.

[0065] The engineering plastic plate 2 is basically the same as the engineering plastic plate in Embodiment 1, the difference is that: the engineering plastic plate adopted by the upper sealing plate and the lower sealing plate contains 31 layers of glass fiber grid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com