Laser direct plating paper and preparation method thereof

A laser direct-plating paper and laser technology, applied in the field of packaging paper, can solve the problems of polluting the environment, and the laser paper is not easy to degrade, and achieves the effects of easy degradation, easy control of production quality, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

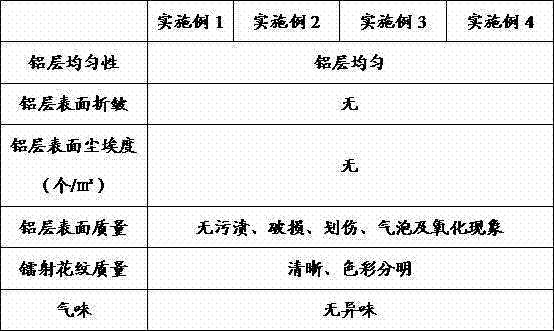

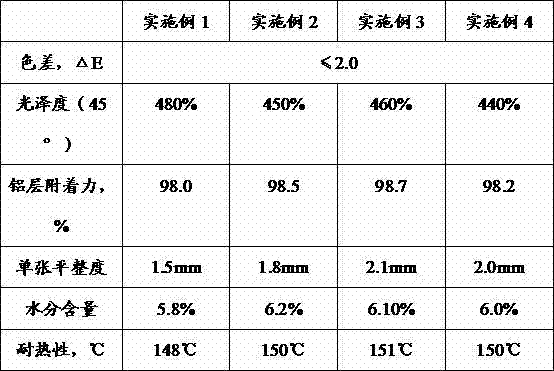

Examples

Embodiment 1

[0027] A preparation method of laser direct-coated paper, said preparation method comprising the following steps:

[0028] (1) Coating: On the light-weight coated paper with a specification of 50g / ㎡, a coating machine is used to coat the laser information layer. The laser information layer is composed of the following components by weight percentage: laser molding resin 65.0%, ethanol 15.0% , ethyl fat 8.0%, methyl ethyl ketone 12.0%, the length of the coating machine used in the present invention is 20m, wherein the length of the oven is 18m, and the oven is divided into six sections, and the temperature of each oven from the entrance to the exit is successively: 120°C, 140°C , 160°C, 180°C, 160°C, 130°C, the speed of the coating machine is 30m / min, the coating moisture is 7g / ㎡, the drying temperature after coating is 120~180°C, and the drying time is 36s.

[0029] (2) Laser molding: The light-coated paper coated with the laser information layer is molded by a molding machine...

Embodiment 2

[0033] A preparation method of laser direct-coated paper, said preparation method comprising the following steps:

[0034] (1) Coating: Use a coating machine to coat the laser information layer on the light-weight coated paper with a specification of 70g / ㎡. The laser information layer is composed of the following components by weight percentage: laser molding resin 68.0%, ethanol 20.0% , ethyl fat 5.0%, butanone 7.0%, the length of the coating machine used in the present invention is 20m, and the length of the oven is 18m, and the oven is divided into six sections. , 160°C, 180°C, 160°C, 130°C, the speed of the coating machine is 40m / min, the coating moisture is 8g / ㎡, the drying temperature after coating is 120~180°C, and the drying time is 27s.

[0035] (2) Laser molding: the light-coated paper coated with the laser information layer is molded by a molding machine, and the plate roller of the molding machine is engraved with several snowflake-shaped laser patterns by laser, a...

Embodiment 3

[0039] A preparation method of laser direct-coated paper, said preparation method comprising the following steps:

[0040] (1) Coating: Use a coating machine to coat the laser information layer on the light-weight coated paper with a specification of 60g / ㎡. The laser information layer is composed of the following components in weight percentage: laser molding resin 65.0%, ethanol 15.0% , ethyl fat 12.0%, butanone 8.0%, the length of the coating machine used in the present invention is 20m, and the length of the oven is 18m, and the oven is divided into six sections. , 160°C, 180°C, 160°C, 130°C, the speed of the coating machine is 40m / min, the coating moisture is 7.5g / ㎡, the drying temperature after coating is 120~180°C, and the drying time is 27s.

[0041] (2) Laser molding: the light-weight coated paper coated with the laser information layer is molded by a molding machine, and the plate roller of the molding machine is engraved with a number of five-pointed star-shaped lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com