a reflective film

A technology of reflective film and graft modification, applied in the field of reflective film, can solve the problems of reduced reflectivity of reflective film, reduced molecular chain, and reduced mechanical properties of reflective film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

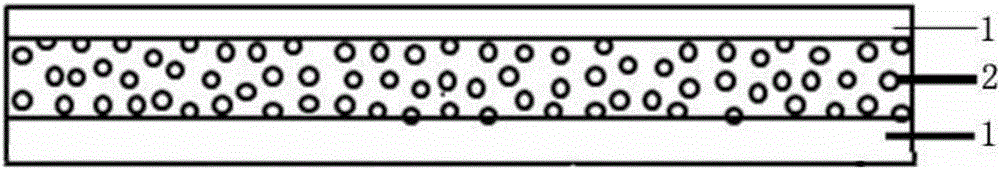

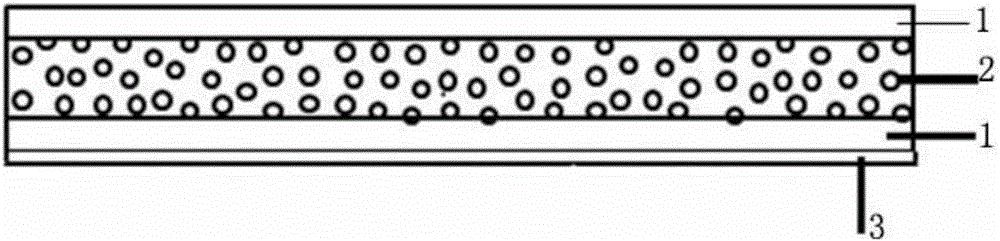

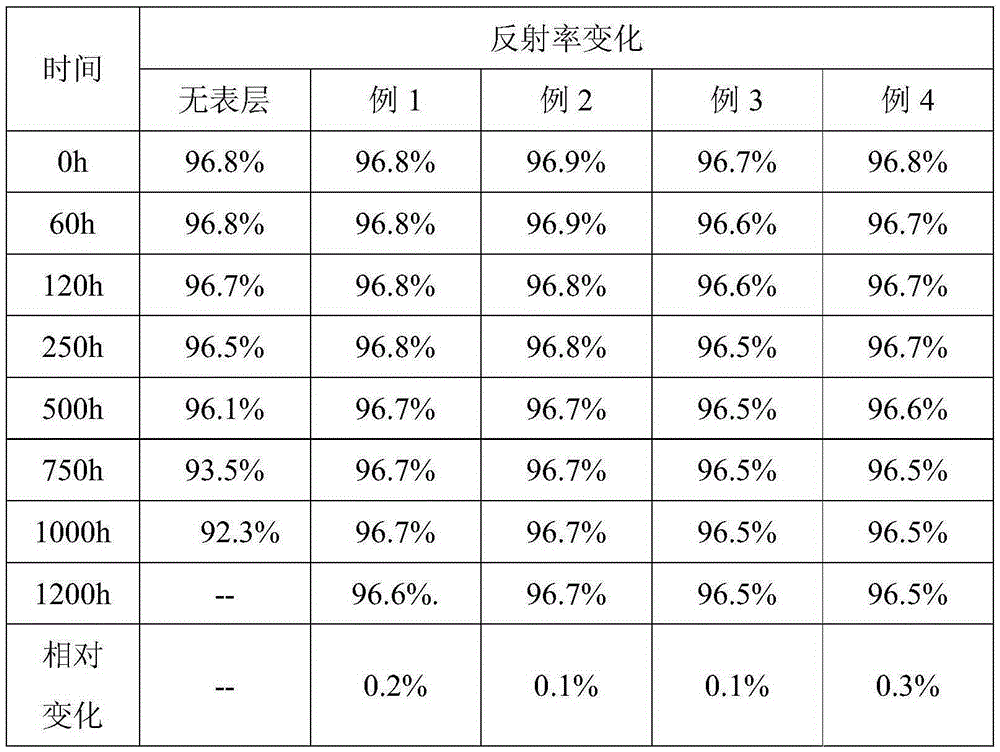

[0029] combine figure 1 with 2 , the ingredients of the core layer 2 include the following ingredients by weight percentage: PLA79%, 15% of titanium dioxide, and 6% of water resistance agent; Silica masterbatch 10%. The ingredients are added to the corresponding extruder and then melted and plasticized. After the melt is filtered and measured, it is compounded in the die (T-shaped or hanger-shaped), and evenly distributed to each point of the film lip to form a melt film. Head temperature 220°C. The melt film is cooled on the surface of the chilled roller at 25°C to form a diaphragm; the diaphragm is preheated at 68°C, stretched longitudinally at 70°C, and the stretching ratio is 3 times, and cooled at 25°C to obtain a uniaxially stretched film. Stretch film. The longitudinally stretched film is preheated at 90°C, stretched 3.2 times transversely, heat-set at 210°C, relaxed by 4% in the width direction, cooled evenly and slowly, and wound up. Among them, the core layer: 8...

Embodiment 2

[0031] The core layer ingredients contain the following ingredients by weight percentage: PLA79%, titanium dioxide 15%, water resistance agent 6%; the surface layer ingredients include the following ingredients by weight percentage: glycidyl ester graft modified molecular weight bimodal distribution polyethylene 90%, silicon dioxide Masterbatch 10%. The ingredients are added to the corresponding extruder and then melted and plasticized. After the melt is filtered and measured, it is compounded in the die (T-shaped or hanger-shaped), and evenly distributed to each point of the film lip to form a melt film. Head temperature 220°C. The melt film is cooled on the surface of the chilled roller at 25°C to form a diaphragm; the diaphragm is preheated at 68°C, stretched longitudinally at 70°C, and the stretching ratio is 3 times, and cooled at 25°C to obtain a uniaxially stretched film. Stretch film. The longitudinally stretched film is preheated at 90°C, stretched 3.2 times transve...

Embodiment 3

[0033]The core layer ingredients contain the following ingredients by weight percentage: PLA79%, titanium dioxide 15%, water resistance agent 6%; the surface layer ingredients include the following ingredients by weight percentage: acrylic acid graft modified molecular weight bimodal distribution polyethylene 90%, silica masterbatch 10%. The ingredients are added to the corresponding extruder and then melted and plasticized. After the melt is filtered and measured, it is compounded in the die (T-shaped or hanger-shaped), and evenly distributed to each point of the film lip to form a melt film. Head temperature 220°C. The melt film is cooled on the surface of the chilled roller at 25°C to form a diaphragm; the diaphragm is preheated at 68°C, stretched longitudinally at 70°C, and the stretching ratio is 3 times, and cooled at 25°C to obtain a uniaxially stretched film. Stretch film. The longitudinally stretched film is preheated at 90°C, stretched 3.2 times transversely, heat-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com