Functional yoghourt rich in unsaturated fattyacids

An unsaturated fatty acid, functional technology, applied in the field of functional yogurt, can solve the problems of α-linolenic acid destruction, reduced nutritional value, several or even dozens of tablets, etc., to reduce cholesterol, regulate intestinal flora, and achieve bright color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

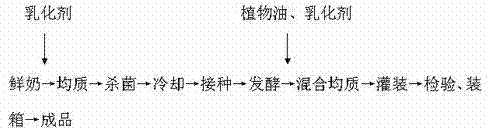

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: prepare yoghurt with cane fruit oil

[0036](1) Preparation of sachaetra fruit oil

[0037] Crush the Miteng nuts to 60 mesh, press at a pressure of 60 MPa, at a temperature of 50°C, press for 60 minutes, and filter to obtain Miteng fruit oil;

[0038] (2) Preparation of cane fruit oil yogurt

[0039] a. Dissolve 0.2 parts of starch octenyl succinate and 0.1 parts of water at 60°C, and then add it to 90 parts of fresh milk;

[0040] b. Homogenize at a pressure of 30MPa for 15 minutes;

[0041] c. Sterilize at 95°C for 5 minutes, then cool to 42°C;

[0042] d. Inoculate Streptococcus thermophilus and Lactobacillus bulgaricus, the two are compounded at a ratio of 1:3, inoculate 2 parts, and ferment for 18 hours at a temperature of 42°C to obtain fermented milk;

[0043] e. Dissolve 1 part of octenyl starch succinate with 0.5 part of water at 60°C, mix with 5 parts of sachaeji fruit oil, add the fermented milk obtained in step d, and mix and homogeni...

Embodiment 2

[0044] Example 2: Preparation of linseed oil yoghurt

[0045] (1) Preparation of linseed oil is the same as that of Example 1 Sateng fruit oil;

[0046] (2) Preparation of linseed oil yogurt

[0047] a. After dissolving 0.3 parts of glyceryl stearate and 0.2 parts of water at 55°C, add it to the milk prepared by 10 parts of milk powder and 95 parts of water;

[0048] b. Pressure 25MPa, homogenization 20min;

[0049] c. Sterilize at 95°C for 5 minutes, then cool to 45°C;

[0050] d. Inoculate Lactobacillus rhamnosus and Lactobacillus, and mix them at a ratio of 1:2, inoculate 2 parts, and ferment for 20 hours at a temperature of 41°C to obtain fermented milk;

[0051] e. Dissolve 0.8 parts of glyceryl stearate and 0.8 parts of water at 50°C, mix with 6 parts of linseed oil, add the fermented milk obtained in step d, and mix and homogenize 3 times at a pressure of 20 Pa to obtain the finished linseed oil yoghurt.

Embodiment 3

[0052] Embodiment 3: Preparation of mixed vegetable oil yoghurt

[0053] (1) The preparation of sachaetra oil, linseed oil or perilla oil is the same as the preparation of sachaetra oil in Example 1;

[0054] (2) Prepare mixed vegetable oil yogurt

[0055] a. After dissolving 0.4 parts of sucrose fatty acid and 0.3 parts of water at 50°C, add it to 95 parts of fresh milk;

[0056] b. Pressure 20MPa, homogenization 20min;

[0057] c. Sterilize at 95°C for 8 minutes, then cool to 40°C;

[0058] d. Inoculate Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus rhamnosus, and Lactobacillus in a ratio of 1:1:2:3, inoculate 3 parts, and ferment at 42°C for 22 hours to obtain fermented milk;

[0059] e. Add 1 part of sucrose fatty acid and 0.5 part of water to dissolve at 60°C, mix with 3 parts of cane oil, 2 parts of linseed oil and 1 part of perilla oil, add the fermented milk obtained in step d, and mix homogeneously twice at a pressure of 25 Pa , to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com