Reverse osmosis membrane and its preparation method and application

A technology of reverse osmosis membrane and membrane casting solution, which is applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc. It can solve the problems of increased membrane pretreatment cost, weak chlorine resistance, and reduced service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

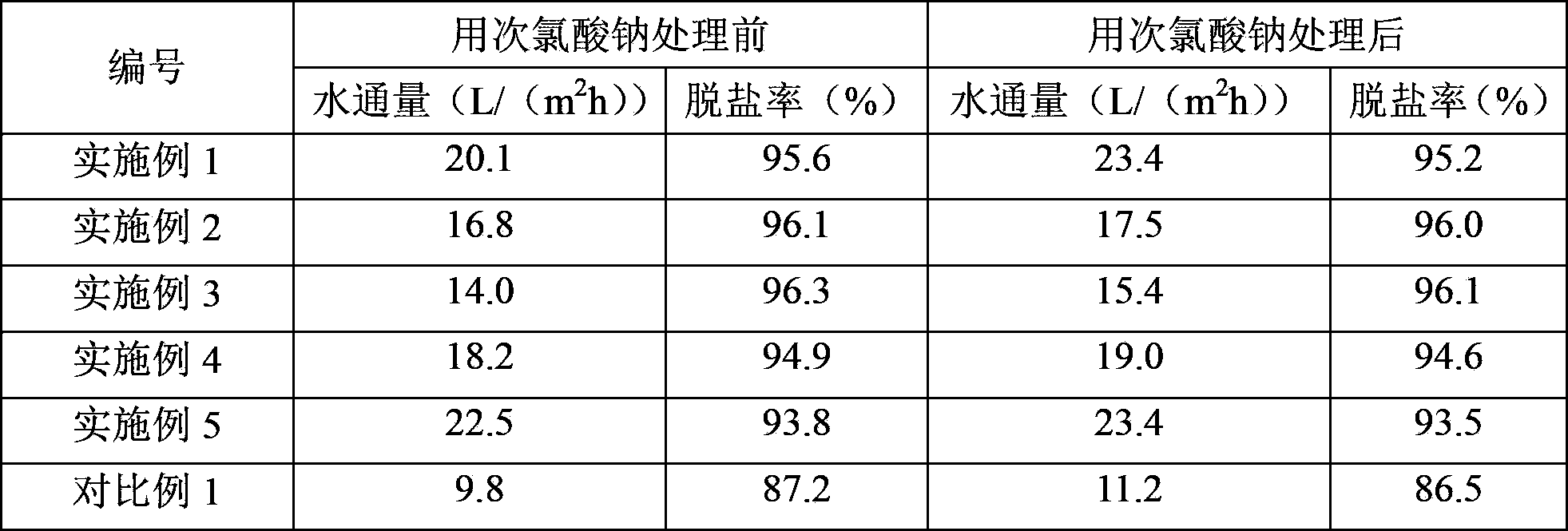

Examples

preparation example Construction

[0031] The preparation method of the reverse osmosis membrane provided by the present invention comprises the steps of uniformly coating the casting solution containing the phenolphthalein type sulfonated polyarylether sulfone having the structure shown in formula (I) and a solvent on the support layer to form a nascent membrane, and applying the The solvent in the nascent membrane is removed to obtain a composite membrane including a laminated support layer and a phenolphthalein-type sulfonated polyarylethersulfone layer, and then a coating solution containing a hydrophilic polymer and water is evenly coated on the phenolphthalein-type sulfonated polyarylethersulfone layer. The surface of the polyarylether sulfone layer is oxidized and thermally cured;

[0032] Formula (Ⅰ),

[0033] Among them, R 1 -R 15 for H or C 1 -C 5 The alkyl group, n≥2.

[0034] The present invention does not specifically limit the dosage of the casting solution and the coating solution, but in ...

Embodiment 1

[0058] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0059] 0.5 g of dried phenolphthalein-type sulfonated polyarylethersulfone P-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd., R 1 -R 14 H, n is 60, ion exchange capacity is 1.37mmol / g) dissolved in a mixed solvent consisting of 30g formic acid, 30g ethylene glycol monomethyl ether and 39.4g deionized water, then add 0.1g lithium chloride and mix Evenly, the casting solution is obtained. Fix the bisphenol A polysulfone ultrafiltration membrane (purchased from Dow Chemical, with a thickness of 125 microns, the same below) on a glass plate, and evenly coat the above casting solution on the bisphenol A polysulfone ultrafiltration membrane The surface was then heat-treated at 70 °C for 30 minutes to remove the solvent, and a composite membrane F1 including a laminated support layer and a phenolphthalein-type sulfonated polyarylethersulfo...

Embodiment 2

[0063] This example is used to illustrate the reverse osmosis membrane provided by the present invention and its preparation method.

[0064] 0.75g of dried phenolphthalein-type sulfonated polyarylethersulfone P-SPAES (purchased from Tianjin Yanjin Technology Co., Ltd., R 1 -R 14 is H, n is 52, and the ion exchange capacity is 1.37mmol / g) is dissolved in a mixed solvent composed of 20g formic acid, 40g ethylene glycol monomethyl ether and 39.1g deionized water, and then 0.15g lithium chloride is added and mixed Evenly, the casting solution is obtained. Fix the bisphenol A polysulfone ultrafiltration membrane on a glass plate, and evenly coat the above-mentioned casting solution on the surface of the bisphenol A polysulfone ultrafiltration membrane, and then heat-treat at 70°C for 30 minutes to remove the solvent, A composite membrane F2 comprising a laminated support layer and a phenolphthalein-type sulfonated polyarylethersulfone layer (thickness 0.25 μm) was obtained.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com