Heavy metal stabilizer used for sludge treatment, and method for treating sludge by adopting it

A heavy metal stabilizer and sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of simple equipment, easy large-scale production, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 30 parts of hydroxyapatite, 30 parts of bentonite, 20 parts of calcium oxide, 14 parts of calcium hydroxide, 5 parts of sodium sulfide, 0.5 parts of sodium edetate, 0.7 parts of carbonamide, polyacrylamide 0.8 part of flocculant, it is placed in the agitator and stirred until mixed evenly to obtain the heavy metal stabilizer; after weighing 5% of the heavy metal stabilizer relative to the total weight of the sludge and adding it all to the sludge, place Stir in a blender until evenly mixed; spread out the sludge and let it dry naturally.

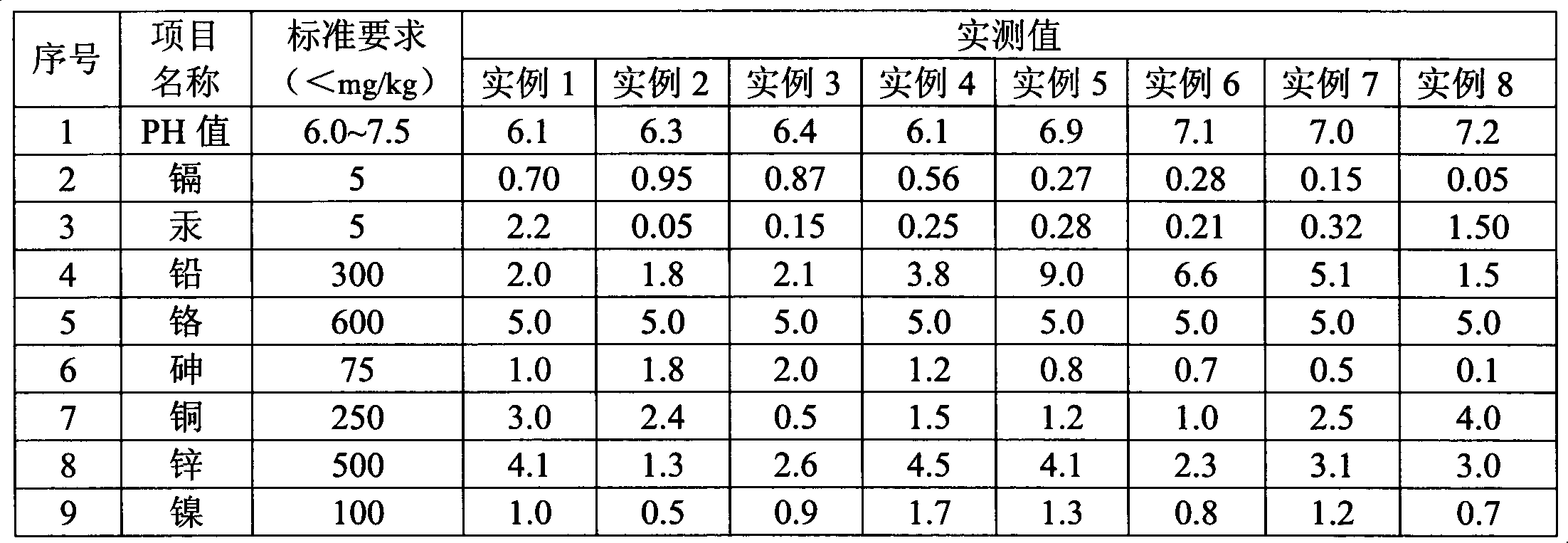

[0033] After 2 days, according to the Solid Waste Toxic Leaching (TCLP) method of the United States Environmental Protection Agency, the heavy metal content in the leachate was measured with an atomic absorption spectrophotometer, and the test results are listed in Table 1.

Embodiment 2

[0035] Weigh 60 parts of hydroxyapatite, 5 parts of calcium peroxide, 12 parts of calcium oxide, 14 parts of calcium hydroxide, 5 parts of calcium sulfide, 1.5 parts of sodium edetate, and 1.7 parts of carbonamide , 1.8 parts of polyacrylamide flocculant, put it in a stirrer and stir until mixed evenly to obtain a heavy metal stabilizer; weigh 5% of the heavy metal stabilizer relative to the total weight of the sludge and add it all to the sludge After neutralizing, put it in a blender and stir until it is evenly mixed; spread out the sludge and let it dry naturally for curing.

[0036] After 2 days, according to the Solid Waste Toxic Leaching (TCLP) method of the United States Environmental Protection Agency, the heavy metal content in the leachate was measured with an atomic absorption spectrophotometer, and the test results are listed in Table 1.

Embodiment 3

[0038] Weigh 30 parts of rock phosphate ore, 26 parts of bentonite, 20 parts of calcium oxide, 14 parts of calcium hydroxide, 5 parts of sodium sulfide, 2.5 parts of sodium edetate, 1.7 parts of carbonamide, polyacrylamide flocculation 1.8 parts of the agent, put it in a stirrer and stir until evenly mixed to obtain the heavy metal stabilizer; weigh 5% of the heavy metal stabilizer relative to the total weight of the sludge and add all of it to the sludge, place in Stir in a blender until evenly mixed; spread out the sludge and let it dry naturally.

[0039] After 2 days, according to the Solid Waste Toxic Leaching (TCLP) method of the United States Environmental Protection Agency, the heavy metal content in the leachate was measured with an atomic absorption spectrophotometer, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com