Preparation method of silane coupling agent and silicone sealant composition

A technology of silane coupling agent and silicone sealant, applied in the field of silicone rubber, can solve the problems of not meeting the requirements for use, not meeting the bonding performance, etc., and achieve the effect of good bonding effect and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

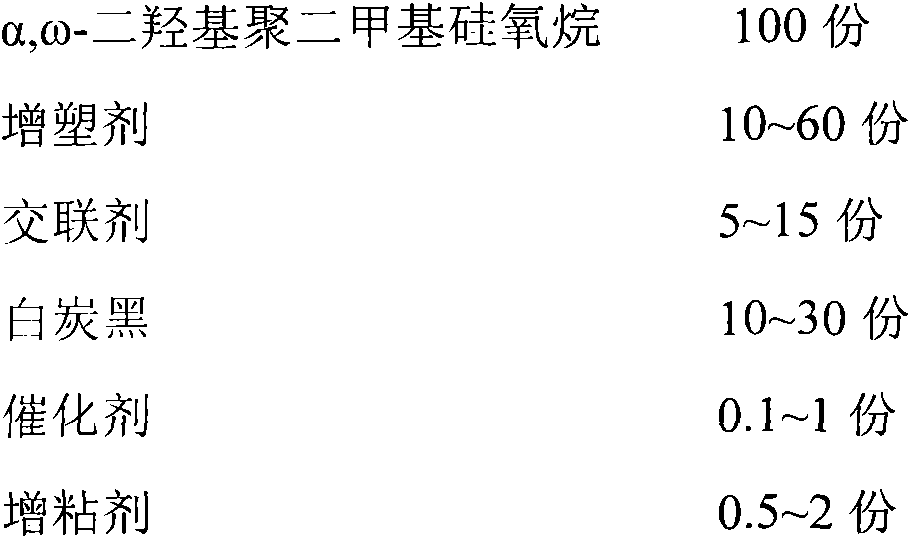

Image

Examples

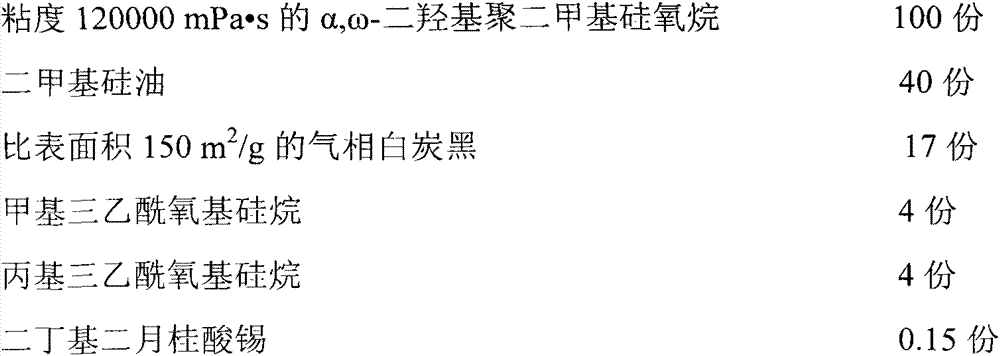

Embodiment 1

[0028]

[0029]

[0030] The preparation method of the acidic transparent silicone sealant of this embodiment is as follows: first add α, ω-dihydroxy polydimethylsiloxane and dimethyl silicone oil in a high-speed planetary disperser, and mix uniformly under vacuum -0.09MPa, Then add cross-linking agent, white carbon black, tackifier and catalyst, and vacuum mix uniformly to prepare rubber compound.

[0031] The obtained acidic transparent silicone sealant was tested for boiling resistance, adhesiveness, and yellowing performance. The results refer to Table 1.

Embodiment 2

[0033]

[0034] The preparation method of the acidic transparent silicone sealant of this embodiment is as follows: first add α, ω-dihydroxy polydimethylsiloxane and dimethyl silicone oil in a high-speed planetary disperser, and mix uniformly under vacuum -0.09MPa, Then add cross-linking agent, white carbon black, tackifier and catalyst, and vacuum mix uniformly to prepare rubber compound.

[0035] The obtained acidic transparent silicone sealant was tested for boiling resistance, adhesiveness, and yellowing performance. The results refer to Table 1.

Embodiment 3

[0037]

[0038] The preparation method of the acidic silicone sealant of this embodiment is as follows: first add α, ω-dihydroxy polydimethylsiloxane and 10% dimethyl silicone oil in the high-speed planetary disperser, and mix well under vacuum -0.09MPa Then, add cross-linking agent, white carbon black, remaining 90% dimethyl silicone oil, tackifier and catalyst, and vacuum mix uniformly to prepare rubber compound.

[0039] The obtained acidic transparent silicone sealant was tested for boiling resistance, adhesiveness, and yellowing performance. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com