A kind of preparation method of instant hydroxypropyl guar gum

A technology of hydroxypropyl guar gum and instant type, which is applied in the field of preparation of instant type hydroxypropyl guar gum, can solve the problems of long preparation time, perishability, low dissolution rate of guar gum or guar gum derivatives, etc., and achieve Simplify the configuration of ground equipment, increase the scale and discharge capacity, and improve the effect of dissolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

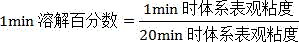

Method used

Image

Examples

Embodiment 1

[0021] The method proceeds as follows:

[0022] a. Add 100 parts by weight of melon collagen powder and 50 parts by weight of industrial methanol in the autoclave at room temperature, stir evenly, then add 10 parts by weight of aqueous sodium hydroxide solution with a mass concentration of 50% dropwise under stirring, soak the alkali 20min; then pass nitrogen to pressurize to 0.3MPa, then reduce to normal pressure, repeat 3 times;

[0023] b. Add 5 parts by weight of propylene oxide and 1 part by weight of potassium chloride to the alkalized guar gum dispersion under stirring, then pressurize to 0.1MPa with nitrogen gas and react at 80°C for 6h;

[0024] c. After the reaction, neutralize with hydrochloric acid to pH = 6, vacuum filter, wash with methanol, dry and pulverize to obtain the product.

Embodiment 2

[0026] The method proceeds as follows:

[0027] a. Add 100 parts by weight of melon collagen powder and 300 parts by weight of industrial methanol in the autoclave at room temperature, stir evenly, then add 50 parts by weight of aqueous sodium hydroxide solution dropwise with a mass concentration of 20% under stirring, soak the alkali 100min; then pass nitrogen to pressurize to 0.5MPa, then reduce to normal pressure, repeat 3 times;

[0028] b. Add 20 parts by weight of propylene oxide and 5 parts by weight of potassium chloride to the basified guar gum dispersion under stirring, then pressurize to 0.4 MPa with nitrogen gas and react at 25 °C for 4 hours;

[0029] c. After the reaction, neutralize with hydrochloric acid to pH=7, vacuum filter, wash with methanol, dry and pulverize to obtain the product.

Embodiment 3

[0031] The method proceeds as follows:

[0032] a. Add 100 parts by weight of melon collagen powder and 150 parts by weight of industrial methanol in the autoclave at room temperature, stir evenly, then add dropwise 30 parts by weight of aqueous sodium hydroxide solution with a mass concentration of 50% under stirring, soak the alkali 60min; then pass nitrogen to pressurize to 0.4MPa, then reduce to normal pressure, repeat 3 times;

[0033] b. Add 10 parts by weight of propylene oxide and 2 parts by weight of potassium chloride to the alkalized guar gum dispersion under stirring, then pressurize to 0.2 MPa with nitrogen gas and react at 50°C for 5 hours;

[0034] c. After the reaction, neutralize with hydrochloric acid to pH=6.5, vacuum filter, wash with weak polar or non-polar solvent, dry and pulverize to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com