Atom transfer radical polymerization method

A technology of atom transfer and free radical, which is applied in the field of organic synthesis, can solve the problem of low conversion rate and achieve the effect of mild polymerization reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

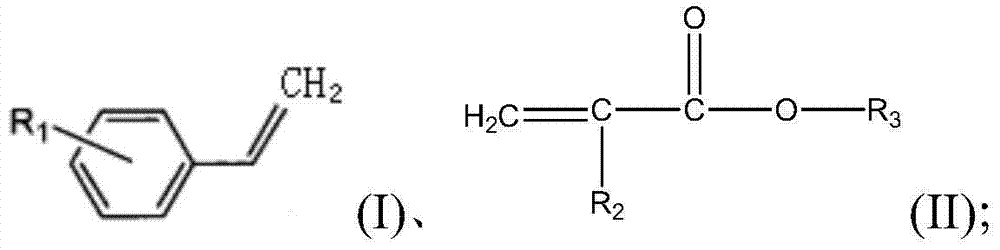

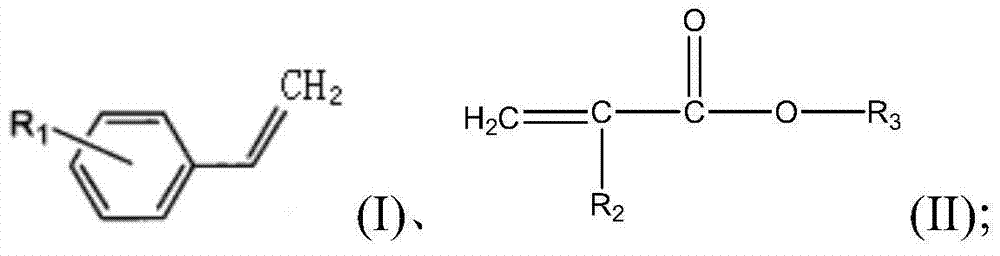

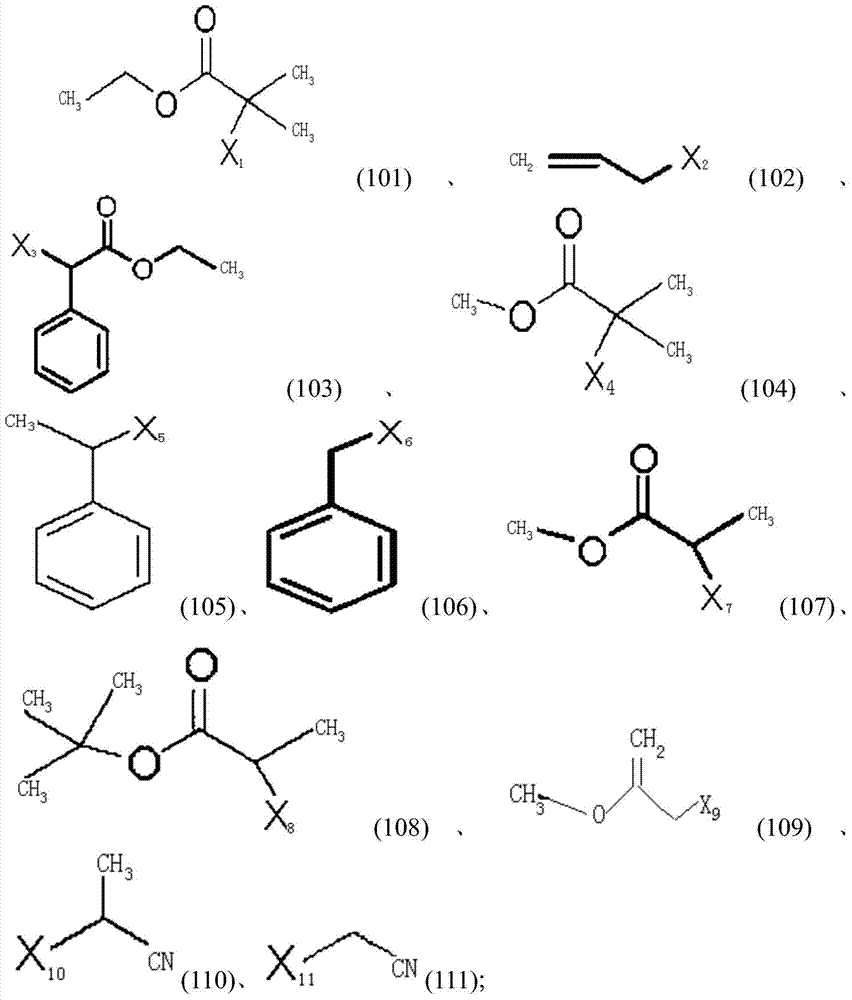

Method used

Image

Examples

Embodiment 1

[0055] 0.21g CuBr 2 , 0.14g of o-dipyridine, 0.14mL of ethyl α-bromoisobutyrate, 20mL of ethanol and 100mL of methyl methacrylate were placed in a 500mL four-neck round bottom flask, three of which were respectively inserted with a working electrode and an auxiliary electrode and the reference electrode, the fourth port is used to add the above materials; the air in the flask is purged with nitrogen gas and then sealed, and the four-necked round bottom flask is placed in an oil bath, heated to 60 ° C, and a voltage of 1.0V is applied. Polymerization was carried out for 6h to obtain polymethyl methacrylate.

[0056] The present invention uses the 1H-NMR method to identify the obtained polymer, indicating that the product obtained by the polymerization reaction is the target product.

[0057] The present invention calculates the conversion rate of the monomer and tests the number-average molecular weight and molecular weight distribution of the polymer according to the test met...

Embodiment 2

[0060] The atom transfer radical polymerization method of the present invention according to the technical solution described in Example 1, the difference lies in that the voltage of this example is 0.5V.

[0061] The present invention uses 1H-NMR to identify the obtained polymer, and the result shows that the polymer in the product is polymethyl methacrylate.

[0062] The present invention calculates the conversion rate of the monomer and tests the molecular weight and molecular weight distribution of the polymer according to the test method described in the above technical solution. The results are shown in Table 1. Table 1 is the experimental results of the polymerization reactions of Examples 1 to 13 of the present invention. .

[0063] It can be seen from Table 1 that the conversion rate of the monomer in Example 2 of the present invention is 4%, the number average molecular weight of the polymer is 8,000, and the molecular weight distribution is 1.13.

Embodiment 3

[0065] The atom transfer radical polymerization method of the present invention according to the technical solution described in Example 1, the difference lies in that the voltage of this example is 1.5V.

[0066] The present invention uses 1H-NMR to identify the obtained polymer, and the result shows that the polymer in the product is polymethyl methacrylate.

[0067] The present invention calculates the conversion rate of the monomer and tests the molecular weight and molecular weight distribution of the polymer according to the test method described in the above technical solution. The results are shown in Table 1. Table 1 is the experimental results of the polymerization reactions of Examples 1 to 13 of the present invention. .

[0068] It can be seen from Table 1 that the conversion rate of the monomer in Example 3 of the present invention is 29%, the number average molecular weight of the polymer is 11,600, and the molecular weight distribution is 1.16.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com