Environment-friendly marine antifouling coating

A marine antifouling and coating technology, which is applied in the field of antifouling coatings and environmentally friendly marine antifouling coatings, can solve problems such as endangering human health and destroying the balance of marine ecology, and achieves the effect of strong inhibition of adhesion and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

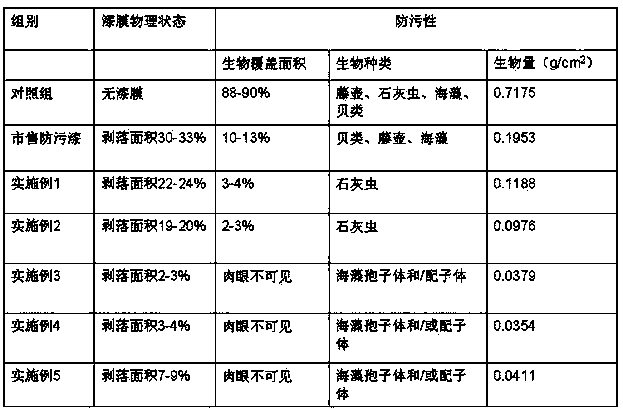

Examples

Embodiment 1

[0015] An environment-friendly marine antifouling paint, comprising the following raw materials in parts by weight: 20 parts of epoxy phenolic resin, 0.5 part of titanium dioxide, 5 parts of titanium dioxide, 3 parts of kaolin, 8 parts of mica powder, 0.2 part of gingerol, 0.2 part of sodium benzoate, 0.2 parts of tannic acid, 0.2 parts of capsaicin, 0.6 parts of P-cinnamic acid sulfate, 18 parts of propylene glycol, 0.05 parts of organic bentonite, 0.02 parts of glyceryl tristearate, and 0.03 parts of polyethylene wax.

Embodiment 2

[0017] An environment-friendly marine antifouling paint, comprising the following raw materials in parts by weight: 45 parts of epoxy phenolic resin, 1 part of titanium dioxide, 10 parts of titanium dioxide, 8 parts of kaolin, 15 parts of mica powder, 2.5 parts of gingerol, 1.5 parts of sodium benzoate, 0.5 parts of tannic acid, 0.5 parts of capsaicin, 4 parts of P-cinnamic acid sulfate, 28 parts of acetic acid, 1 part of modified hydrogenated castor oil, 0.5 parts of glyceryl tristearate, 0.2 parts of polyethylene wax, stearic acid 0.3 parts of zinc.

Embodiment 3

[0019] An environmentally friendly marine antifouling paint, comprising the following raw materials in parts by weight: 25 parts of epoxy phenolic resin, 0.7 part of titanium dioxide, 7 parts of titanium dioxide, 5 parts of kaolin, 10 parts of mica powder, 2 parts of gingerol, 2 parts of sodium benzoate, 0.5 parts of tannic acid, 0.5 parts of capsaicin, 2 parts of P-cinnamic acid sulfate, 21 parts of butyl acetate, 0.5 parts of fumed silicon dioxide, 0.2 parts of glyceryl tristearate, 0.1 parts of polyethylene wax, stearin Zinc acid 0.1 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com