Coking-inhibition hydrocarbon cracking furnace pipe and preparation method thereof

A technology for hydrocarbon cracking furnace tubes and cracking furnace tubes, which is applied in cracking, non-catalytic thermal cracking, ion implantation plating, etc., and can solve problems such as anti-coking, reduced carburization resistance, and inability to use old furnace tubes, etc., to achieve Small thermal stress, inhibition of coking, fine particle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

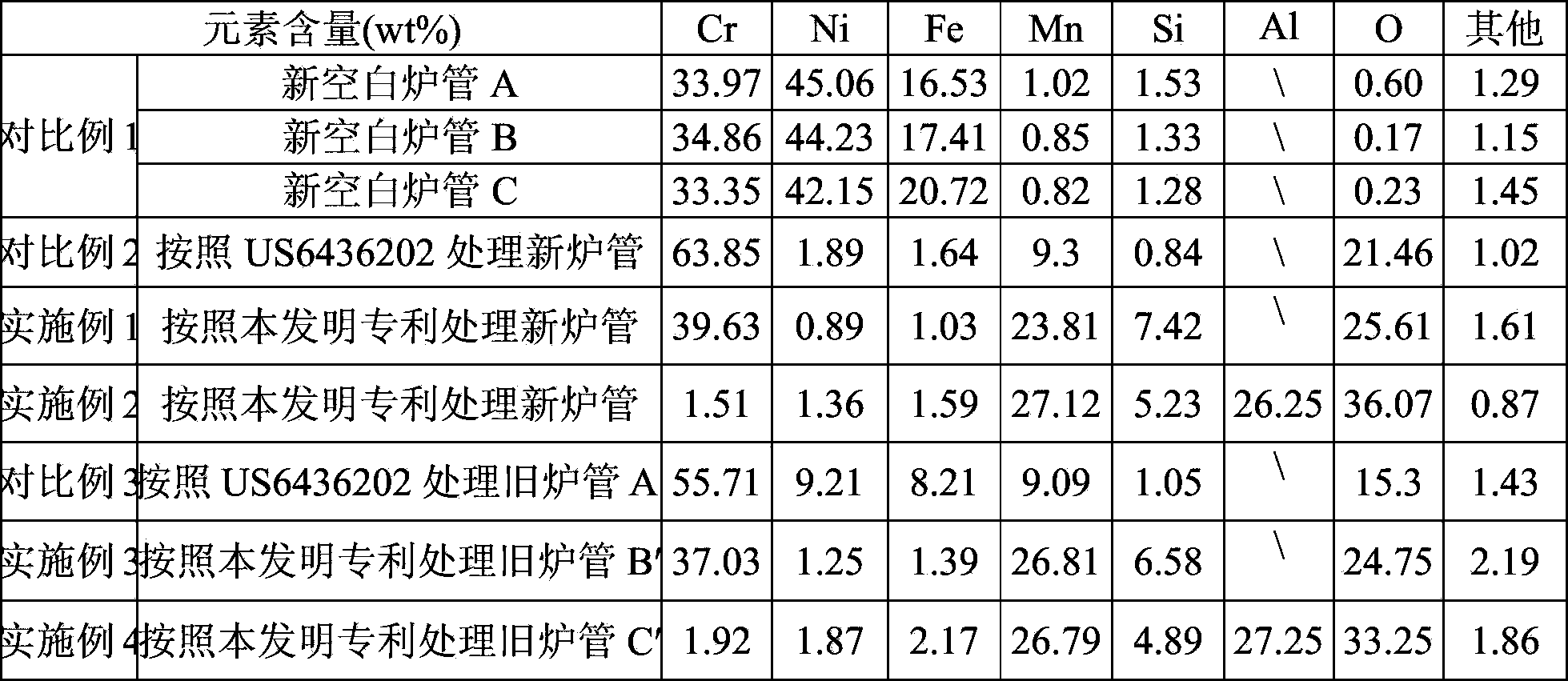

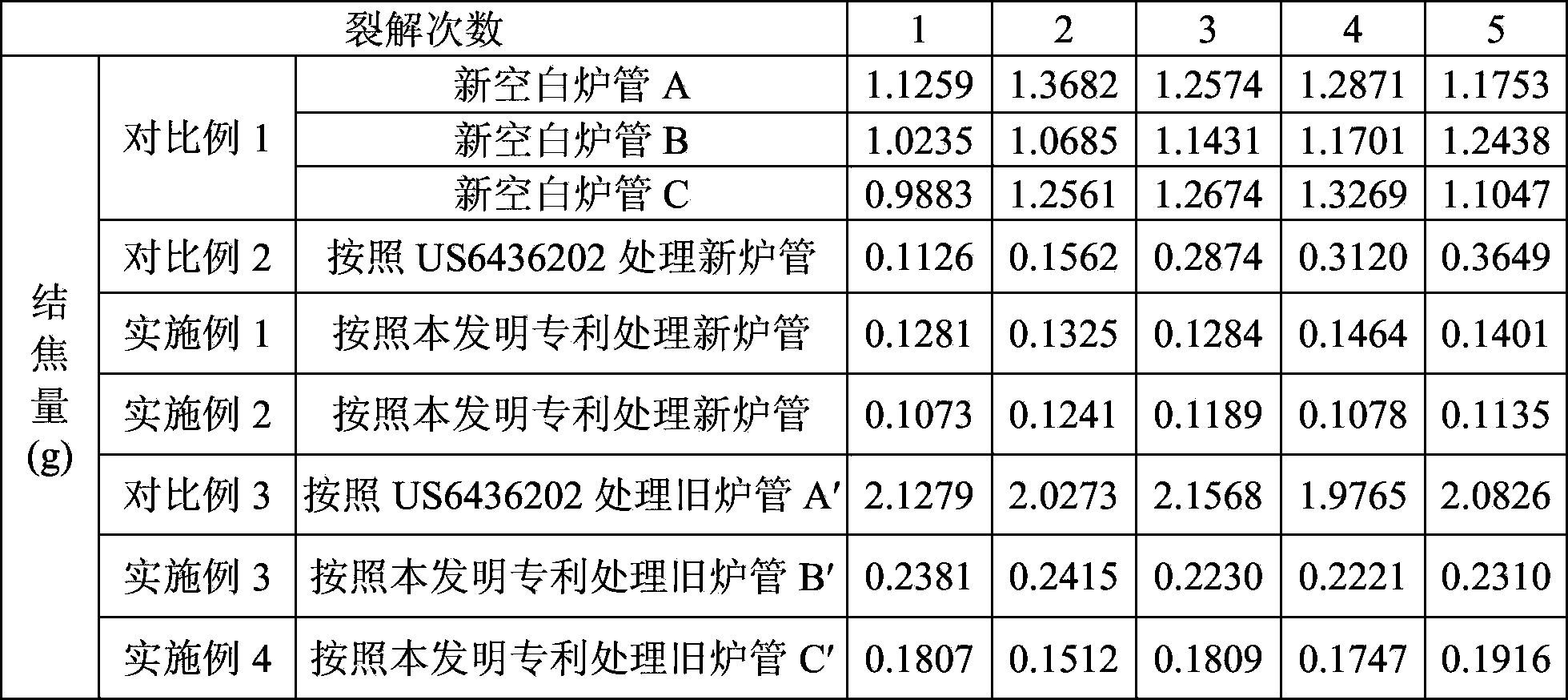

[0045] A new furnace tube with the same size and material as that of Comparative Example 1 was used, and the furnace tube was coated according to the method of the present invention. Use the new furnace tube as the barrel-shaped cathode, place the manganese material in the furnace tube, and glow discharge for 5 hours in a low-vacuum argon protection atmosphere of 800 ° C and 0.5 Pa. The environmental scanning electron microscope observation is about 0.3mm. The furnace tube containing the manganese permeation layer was first heated in 99.97% H on the device described in Comparative Example 1 2 -0.03%H 2 O(H 2 with H 2 The molar ratio of O is 3332:1) in an atmosphere of 1000 ° C for 20 hours, and then in 50% Ar-49.7% H 2 -0.3%H 2 O(H 2 with H 2 The molar ratio of O is 166:1) in an atmosphere at 1000°C for 10 hours. After cooling, the composition of the inner surface of the furnace tube was analyzed with an X-ray energy dispersive spectrometer (EDS). The results are shown ...

Embodiment 2

[0048]A new furnace tube with the same size and material as that of Comparative Example 1 was used, and the furnace tube was coated according to the method provided by the present invention. Use a new furnace tube as a barrel-shaped cathode, place manganese and aluminum materials in the furnace tube, and glow discharge for 5 hours in a low-vacuum argon protective atmosphere at 800 ° C and 0.5 Pa, and the formed manganese and aluminum permeation layer Observe about 0.4mm with XL-30 field emission environment scanning electron microscope. The furnace tube containing the permeable layer is at 99.97% H on the device described in Comparative Example 1 2 -0.03%H 2 O (the molar ratio of H2 to H2O is 3332:1) atmosphere at 1000 ° C for 20 hours, after cooling, the composition of the inner surface of the furnace tube was analyzed by X-ray energy dispersive spectrometer (Energy Dispersive Spectrometer referred to as EDS). The results are shown in Table 2.

[0049] Using the cracking co...

Embodiment 3

[0054] The furnace tube used is an old furnace tube, which is the furnace tube B that has undergone cracking and charring five times in Comparative Example 1, numbered B', and the furnace tube is coated according to the method provided by the present invention. The furnace tube B' is used as the barrel-shaped cathode, the manganese material is placed in the furnace tube B', and the glow discharge is performed for 5 hours in a low-vacuum argon protection atmosphere of 800 ° C and 0.5 Pa, and the formed manganese element permeation layer is used XL- The scanning electron microscope observation of the 30 field emission environment is about 0.4mm. Contain the furnace tube of permeation layer on the device described in comparative example 1. Contain the furnace tube of manganese permeation layer on the device described in comparative example 1. 2 -0.05%H 2 O(H 2 with H 2 The molar ratio of O is 1999:1) in the atmosphere of 1000 ° C for 20 hours, and then in 50% Ar-49.4% H 2 -0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com