Membrane microalgae photobioreactor for realizing in-situ solid-liquid separation and culture method thereof

A technology of photobioreactor and solid-liquid separation, applied in photobioreactor, special-purpose bioreactor/fermenter, microbial-based method, etc., can solve the problems of low nitrogen and phosphorus concentration, increasing nitrogen and phosphorus supply, Unfavorable for microalgae cell harvesting and other issues, to achieve high nitrogen and phosphorus absorption rate, increase nutrient load, and high microalgae production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

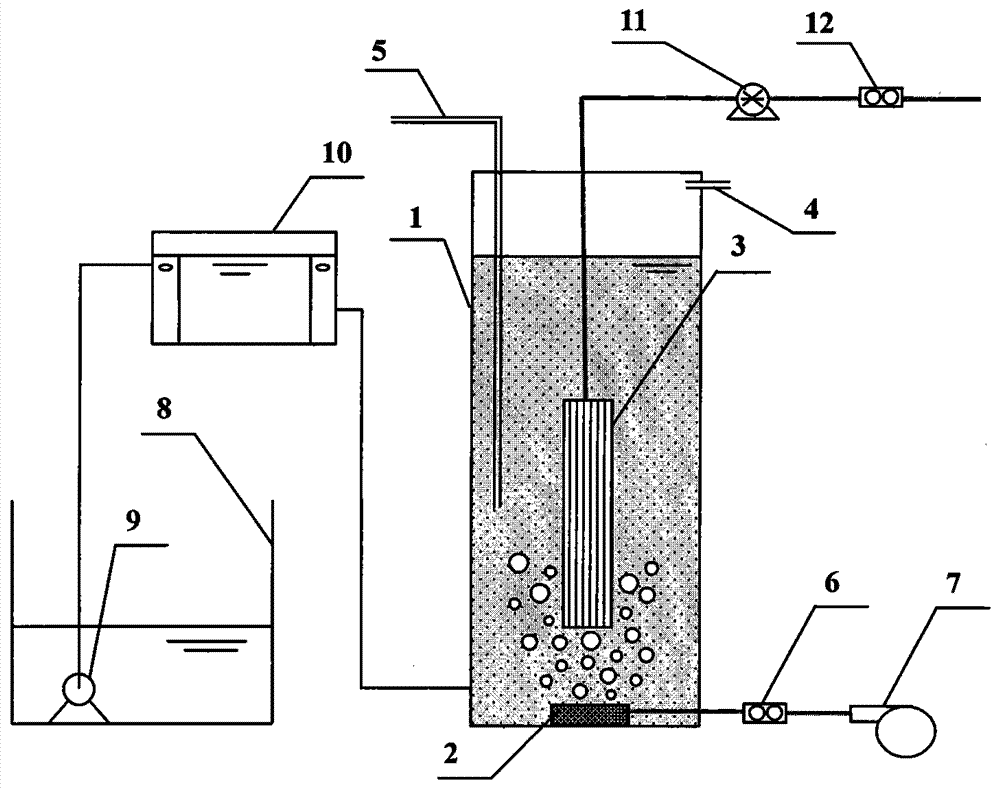

[0022] Referring to the accompanying drawings, a membrane microalgae photobioreactor that realizes in-situ solid-liquid separation, the microalgae culture solution in the water inlet tank 8 enters the liquid level balance water tank 10 through the water pump 9, and the water outlet end of the liquid level balance water tank 10 passes through the water inlet The water pipe communicates with the lower end of the reactor main body 1, so as to input the microalgae culture solution into the reactor and keep the water level at a constant position. The outer cylinder of the reactor main body 1 is made of transparent plexiglass, with an air outlet pipe 4 on the side of the upper end, a sampling and microalgae discharge pipe 5 on the top, and a microporous diffuser 2 at the bottom, and the microporous diffuser 2 passes through an air flow meter 6 is connected with air compressor 7. A hollow fiber membrane module 3 is arranged inside the reactor main body 1, and is connected to a consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com