Method for comprehensively utilizing lepidolite mineralogical reconstruction lithium-extraction slags

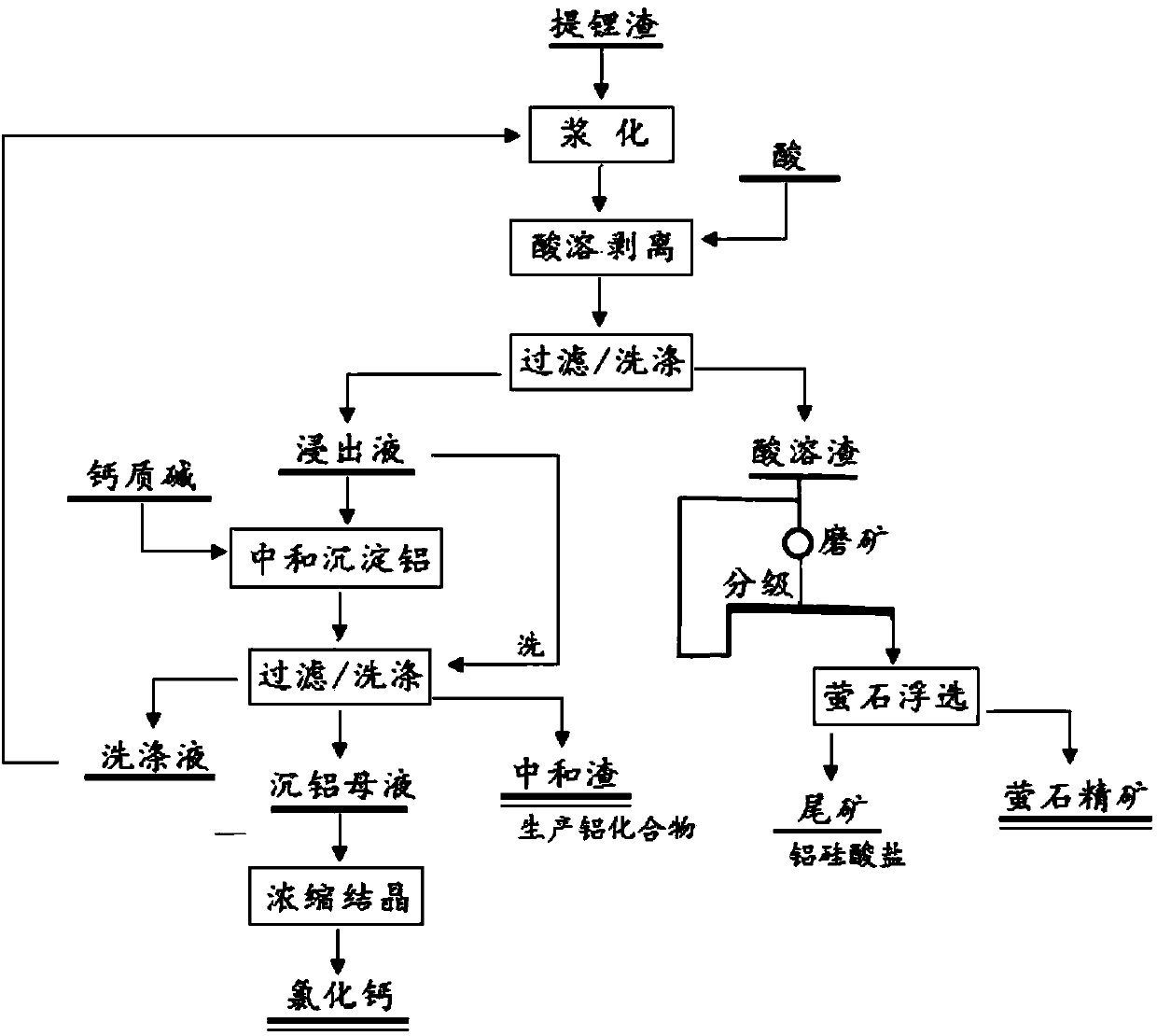

A technology for extracting lithium slag and lepidolite, which is applied in the field of mineral processing, can solve the problems of comprehensive utilization of lithium extraction slag and achieve the effects of expanding comprehensive utilization rate, short treatment process, and less consumption of chemical materials and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the reaction kettle, the leached slag is slurried with the aluminized slag washing liquid at a liquid-solid ratio of 2:1, heated to about 90°C, and about 0.5 of the slag is added to industrial concentrated hydrochloric acid for acid leaching treatment; the treatment time is about 0.5 hours .

[0043] After the acid leaching is completed, filter and wash to separate the acid-dissolved slag and the leachate. Transfer the leaching liquid into a heating reaction kettle, heat and keep it warm to about 65°C, add -600 mesh calcium oxide powder to carry out solid phase conversion reaction, the time is about 6 hours, and the final pH value is controlled to be 9.5-10, and aluminum hydroxide is precipitated.

[0044] After the solid-liquid separation, the neutralized slag of precipitated aluminum is transferred to the heating and stirring reactor, and the neutralized slag is slurried and washed with the lithium extraction slag acid solution at a temperature of about 80°C for ab...

Embodiment 2

[0050] In the reaction kettle, the leached slag is slurried with the aluminized slag washing liquid at a liquid-solid ratio of 5:1, heated to about 50°C, and about 0.7% of the slag is added to industrial concentrated hydrochloric acid for acid leaching treatment; the treatment time is about 2 hours .

[0051] After the acid leaching is completed, filter and wash to separate the acid-dissolved slag and the leachate. Transfer the leaching solution into a heating reaction kettle, heat and keep it warm to about 40°C, add -800 mesh calcium oxide powder to carry out solid phase conversion reaction, the time is about 2 hours, and the final pH value is controlled to be 9.5-10, and aluminum hydroxide is precipitated.

[0052] After the solid-liquid separation, the neutralization slag of aluminum precipitation is transferred to the heating and stirring reactor, and the neutralization slag is slurried and washed with the acid solution of the lithium extraction slag at a temperature of ab...

Embodiment 3

[0058] In the reaction kettle, the leached slag is slurried with the aluminized slag washing liquid at a liquid-solid ratio of 3:1, heated to about 70°C, and about 0.3 of the slag volume is added to industrial concentrated hydrochloric acid for acid leaching treatment; the treatment time is about 3 hours .

[0059] After the acid leaching is completed, filter and wash to separate the acid-dissolved slag and the leachate. Transfer the leaching solution into the heating reaction kettle, heat and keep it warm to about 80°C, add -400 mesh calcium oxide powder to carry out solid phase conversion reaction, the time is about 4 hours, the final pH value is controlled to be 9-9.5, and aluminum hydroxide is precipitated.

[0060] After the solid-liquid separation, the neutralization slag of aluminum precipitation is transferred to the heating and stirring reactor, and the neutralization slag is slurried and washed with the lithium extraction slag acid solution at a temperature of about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com