Method for extracting shale oil gas by oil shale in-situ topochemical method

A technology for shale oil and gas and oil shale, which is applied in the field of oil shale in-situ local chemical extraction of shale oil and gas, can solve the problems of difficult control of the reaction process, large excavation workload, large heat loss, etc., so as to reduce the production cost. and commercial risks, reducing construction difficulty and cost, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

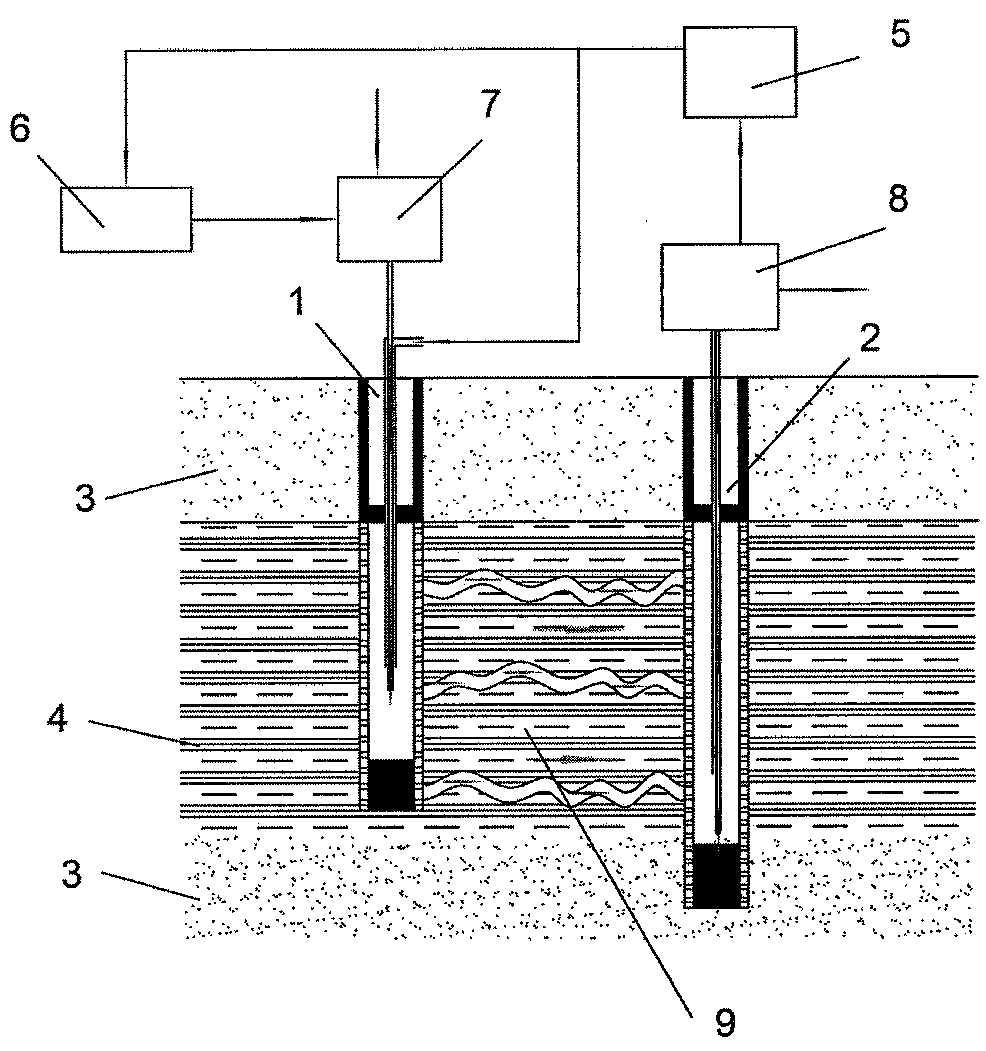

[0029] Example 1: if figure 1 Shown, be double well form, the specific steps of the present embodiment are as follows:

[0030] (1) Drilling and Completion:

[0031] a. Drill two wells, one well is the heat injection well 1, and the other well is the production well 2, and the distance between the boreholes of the two wells is 25m;

[0032] b. Drill two wells with the same technology, the hole diameter is 150mm, the hole diameter is 150mm from 0 to 65m, and a 146mm casing is installed; The direction points to another well, the well is cemented between the casing and the well wall, and the cement base is poured at the bottom of the well;

[0033] c. The two wells are connected through hydraulic fracturing fractures, and the production well and the heat injection well can be interchanged during the implementation process;

[0034] d. An injection channel should be formed in the heat injection well 1, and a gas outflow channel and an oil pumping channel should be formed in the...

example 2

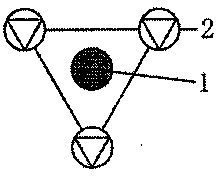

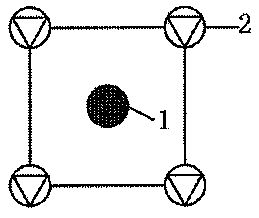

[0055] Example 2: if Figure 4 As shown, the group well mode, the specific steps of the present embodiment are as follows:

[0056] a. According to the distribution and trend of the oil shale layer, select the specific locations of the heat injection wells and production wells, arrange 24 production wells 2 and 7 heat injection wells 1 in the delineated working area, and the plane distribution of the production wells 2 is 7 six 7 heat injection wells 1 are located in the middle of 7 hexagonally distributed production wells 2, the distance between adjacent production wells 2 and production wells 2 is 25m, and the distance between adjacent heat injection wells 1 and production wells 2 The distance is 25m;

[0057] b. The production wells 2 are distributed in a hexagon with the heat injection well 1 as the center;

[0058] c. Each heat injection well 1 and production well 2 are connected through hydraulic fracturing fractures;

[0059] d. A gas injection channel should be form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com