Ceramic green sheets and laminated ceramic electronic components

A technology for ceramic green sheets and ceramic materials, applied in ceramic molding machines, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as damage, difficulty in peeling, and reduced strength of ceramic green sheets, and achieve Effects of increasing transport speed, suppressing electrification adhesion, and reducing frictional electrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

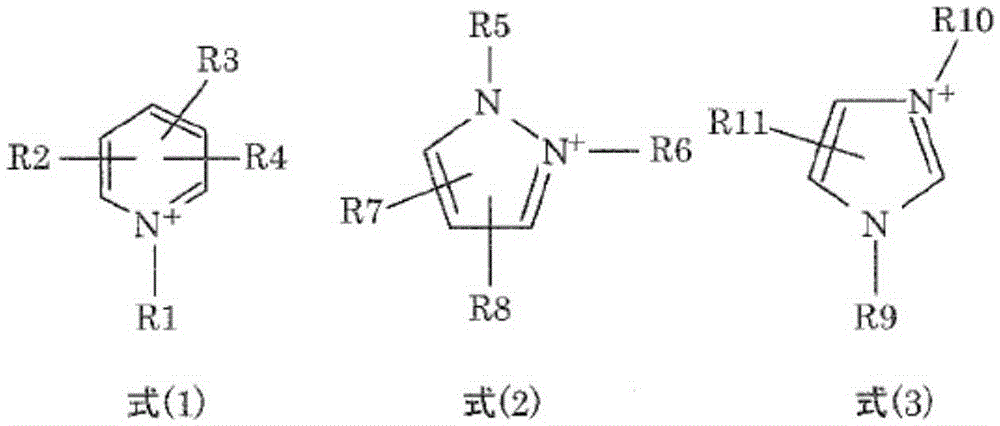

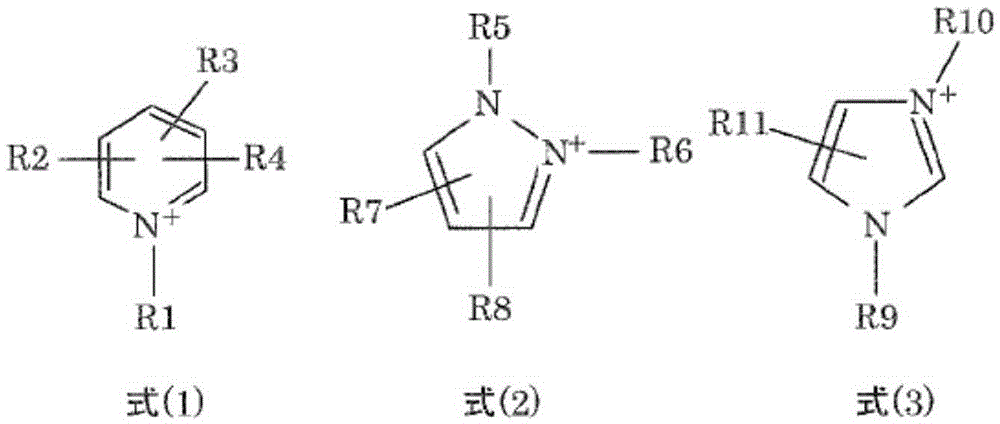

[0144] Put 100g of barium titanate (average particle diameter calculated from BET specific surface area: 50nm) and 4.0g of dispersant B6 (active ingredient) into a 500mL container together with 500g of zirconia beads with a diameter of 1mm, add toluene / ethanol= A mixed solvent of 48 / 52 (volume ratio) was adjusted so that the solid content concentration of barium titanate was 50% by weight, and dispersion treatment was performed for 96 hours using a table-top bead mill.

[0145] Next, 14.0 g of polyvinyl butyral resin, 2.80 g of dioctyl phthalate, 1.0 g of cationic compound A1, and a mixed solvent of toluene / ethanol=48 / 52 (volume ratio) were added to the above dispersion treatment liquid, The solid content concentration of the barium titanate was adjusted to be 35% by weight, and the mixture was mixed for 2 hours with a benchtop bead mill, and then the zirconia beads were removed by filtration to obtain a ceramic slurry.

[0146] Next, the ceramic slurry was molded into a sheet...

Embodiment 2)

[0149] A ceramic green sheet was produced in the same manner as in Example 1 except that the cationic compound A2 was used instead of the cationic compound A1 in Example 1, and a multilayer ceramic capacitor was produced using the ceramic green sheet.

Embodiment 3)

[0151] A ceramic green sheet was produced in the same manner as in Example 1 except that the cationic compound A3 was used instead of the cationic compound A1 in Example 1, and a multilayer ceramic capacitor was produced using the ceramic green sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com