Super elastic zirconium alloy for biological use, medical instrument and glasses

A living tissue and superelastic technology, applied in tissue regeneration, glasses/goggles, instruments, etc., to achieve high compatibility and high processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

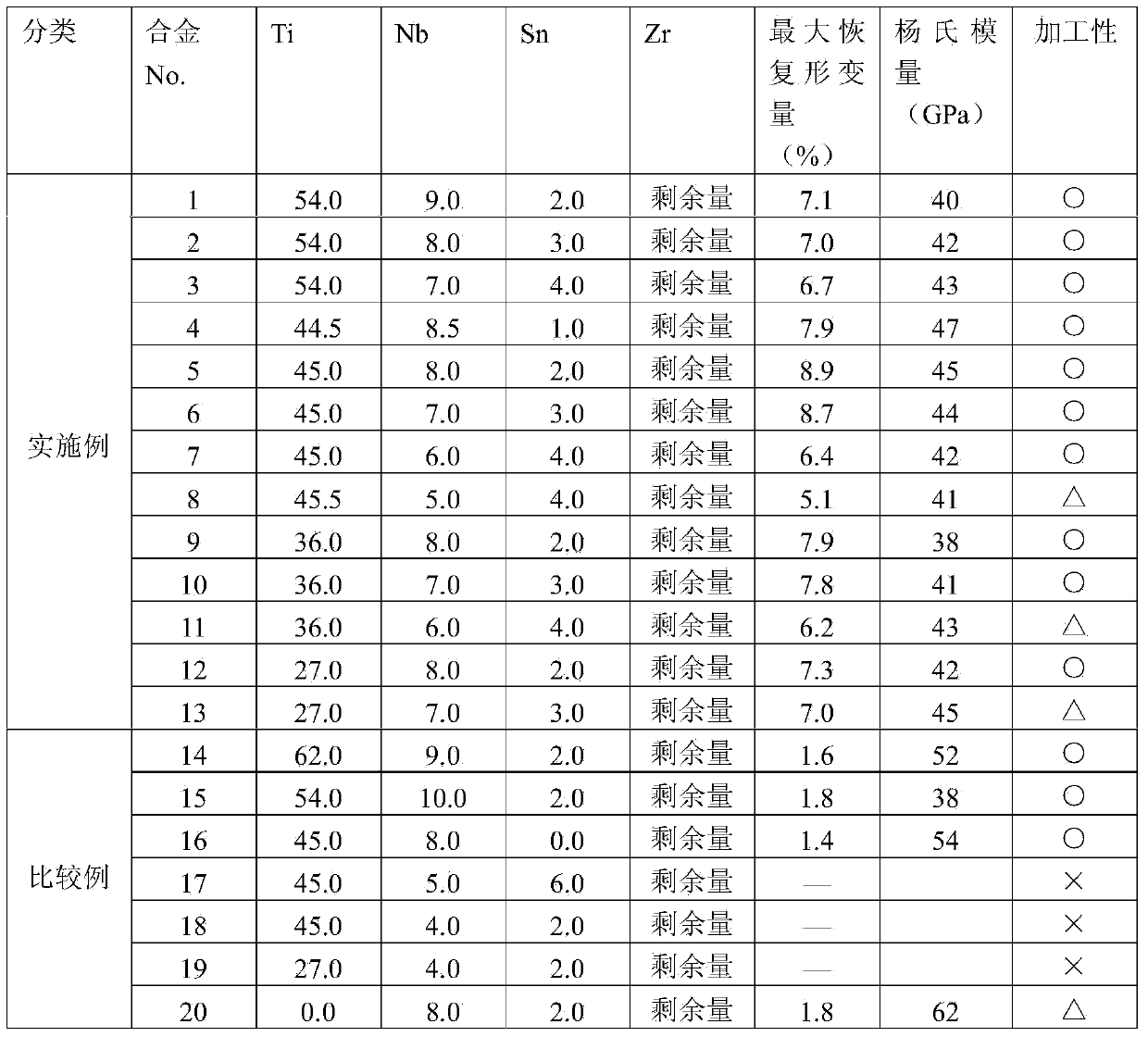

[0037] Specific examples of embodiments of the present invention will be described below, but the present invention is not limited to the following examples.

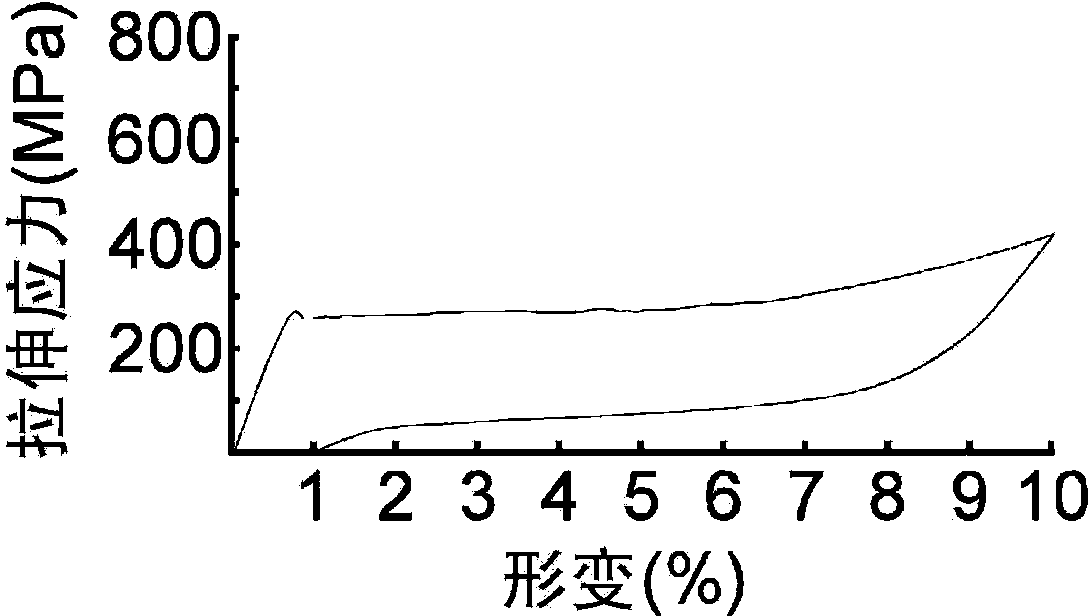

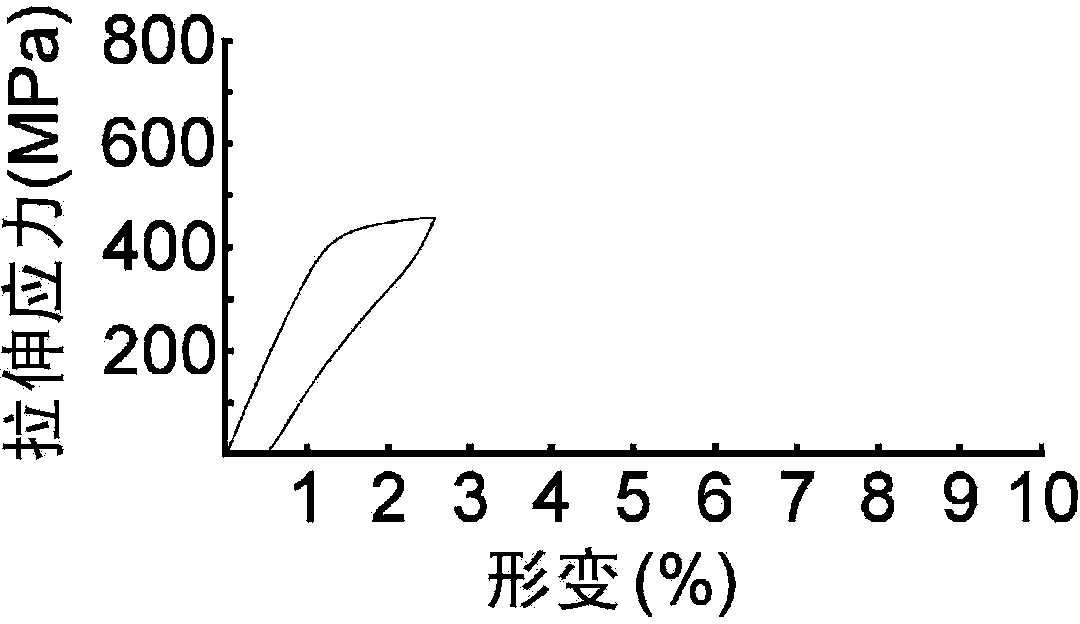

[0038] The alloy of the present invention is a zirconium-based alloy mainly composed of zirconium (Zr). In addition, the alloy of the present invention has the effect of lowering the transition temperature from the β phase, which is the parent phase of zirconium's martensite (martensite) transformation at room temperature, to the α phase, that is, contains the β phase that stabilizes the β phase of zirconium. The elements titanium (Ti) and niobium (Nb), the alloy undergoes a thermoelastic martensitic (martensite) transformation.

[0039] In addition, Ti and Nb dissolve in Zr, and also undertake the role of dissolution strengthening, which increases the critical stress of sliding deformation, makes sliding deformation difficult to occur, and achieves good superelasticity. In addition, for Ti, since the variation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com