Ice cream coating grease

An ice cream and coating technology, applied in frozen desserts, food science, applications, etc., can solve the problems of slow crystallization rate and difficulty in coating with ice cream, achieve fast crystallization rate, facilitate absorption, and increase crystallization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of ice cream coating grease provided by the invention comprises the following steps:

[0048] The camphor tree seed oil, palm kernel stearate and palm stearate mixture are reacted at 60-100 DEG C for 30-60 minutes in the presence of an esterification catalyst.

[0049] In a preferred embodiment of the present invention, the weight ratio of the camphor tree seed oil, palm kernel stearate and palm stearate is 10-30:60-80:1-10, preferably, the camphor tree seed oil , palm kernel stearate, palm stearate weight ratio is 15-27:65-77:3-8.

[0050] Preferably, based on the total weight of the camphor tree seed oil, palm kernel stearate, palm stearate, the weight of the camphor tree seed oil is 10% by weight, 11% by weight, 12% by weight, 13% by weight , 14% by weight, 15% by weight, 16% by weight, 17% by weight, 18% by weight, 19% by weight, 20% by weight, 21% by weight, 22% by weight, 23% by weight, 24% by weight, 25% by weight, 26% by weight % by weig...

Embodiment 1

[0087] Embodiment 1: raw material preparation

[0088] The preparation method of the refined camphor tree seed oil is as follows: after the camphor tree seeds are crushed and the pulp is removed, the camphor tree seed crude oil is extracted by organic solvents such as petroleum ether or ether; the camphor tree seed crude oil is filtered, degummed, deacidified, decolorized, deodorized, etc. process to prepare and obtain refined camphor tree seed oil.

[0089] The preparation method of palm kernel stearate is as follows: the stearin part obtained by heating and melting the refined palm kernel oil and then undergoing an oil fractionation process has an iodine value of 1-8.

[0090] The preparation method of palm stearate is as follows: heat and melt the refined palm oil and then undergo the oil fractionation process to obtain the stearin part, which has an iodine value of 10-25.

Embodiment 2

[0091] Embodiment 2: grease preparation

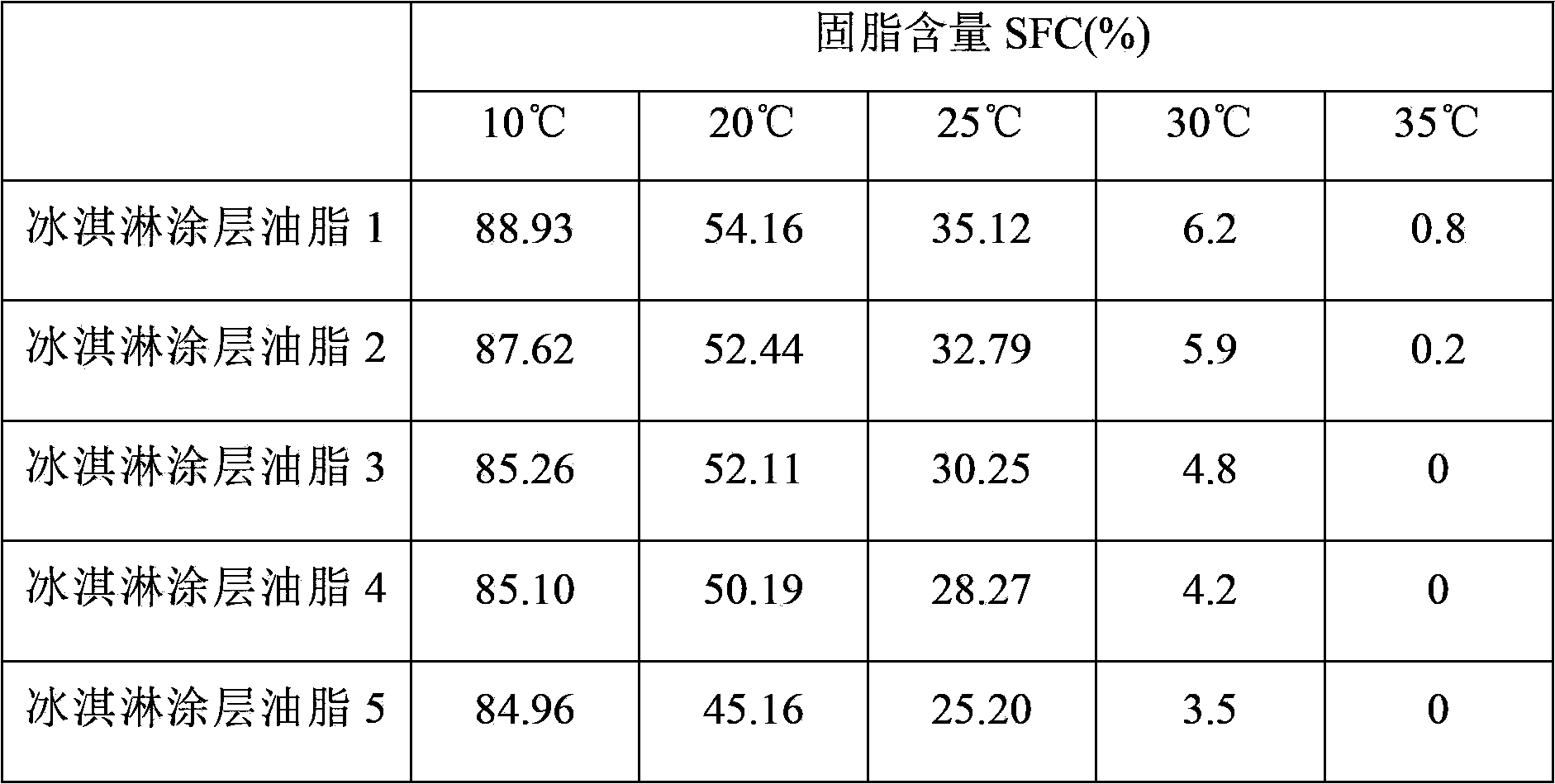

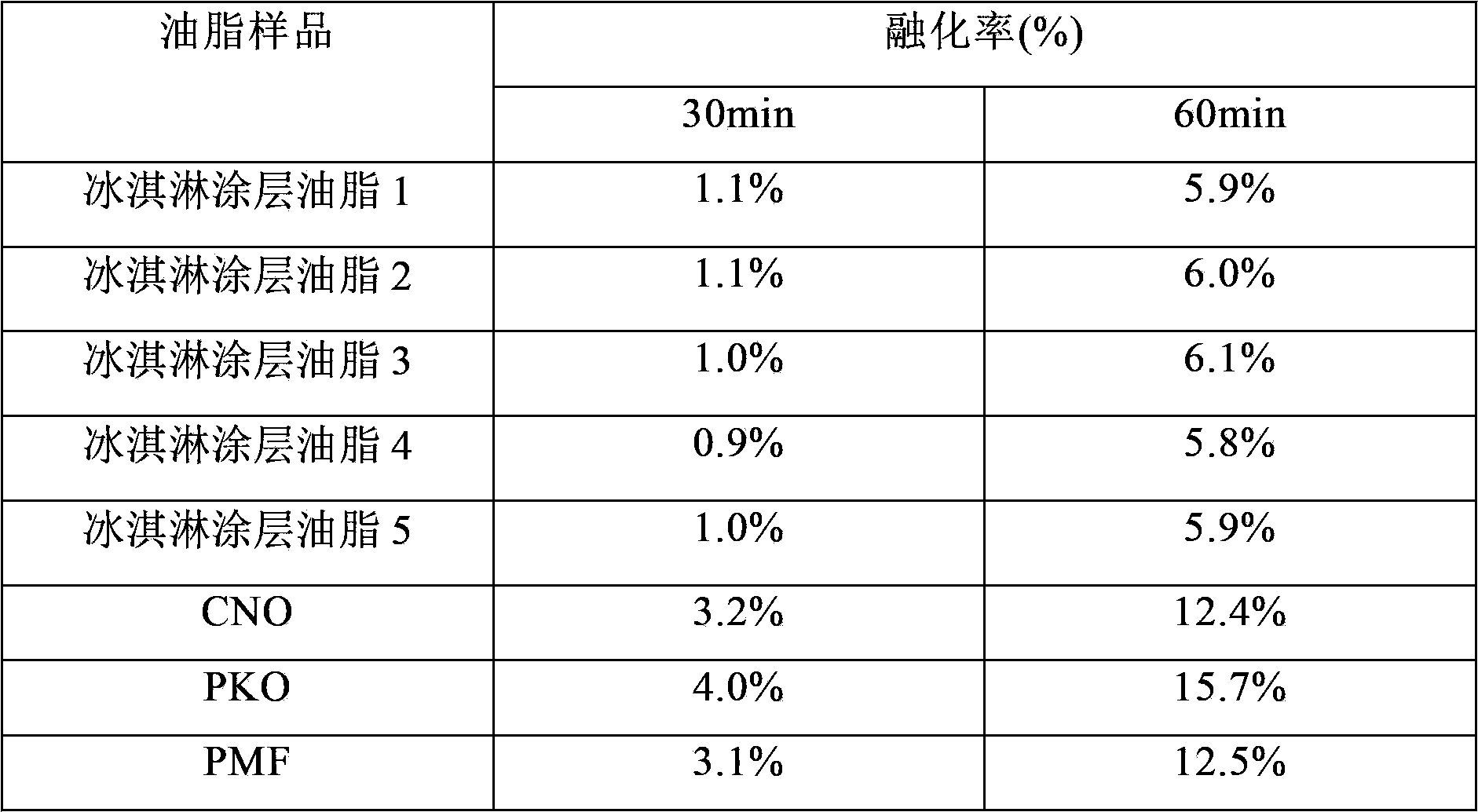

[0092] According to the ratio in Table 1, the refined camphor tree seed oil, palm kernel stearate and palm stearate were mixed, dehydrated and dried at 90-120° C. to obtain mixtures 1-5 respectively.

[0093] Table 1,

[0094]

[0095] mixture 2

[0096] Mix the prepared mixture 1-5 with the transesterification catalyst, then react at 60-100°C for 30-60 minutes, dry and dehydrate the obtained reaction product, then filter, degumming, deacidification, decolorization, deodorization and refining Process treatment to obtain the corresponding ice cream coating grease 1-5, wherein the transesterification catalyst used is sodium methoxide, sodium ethoxide or their mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com