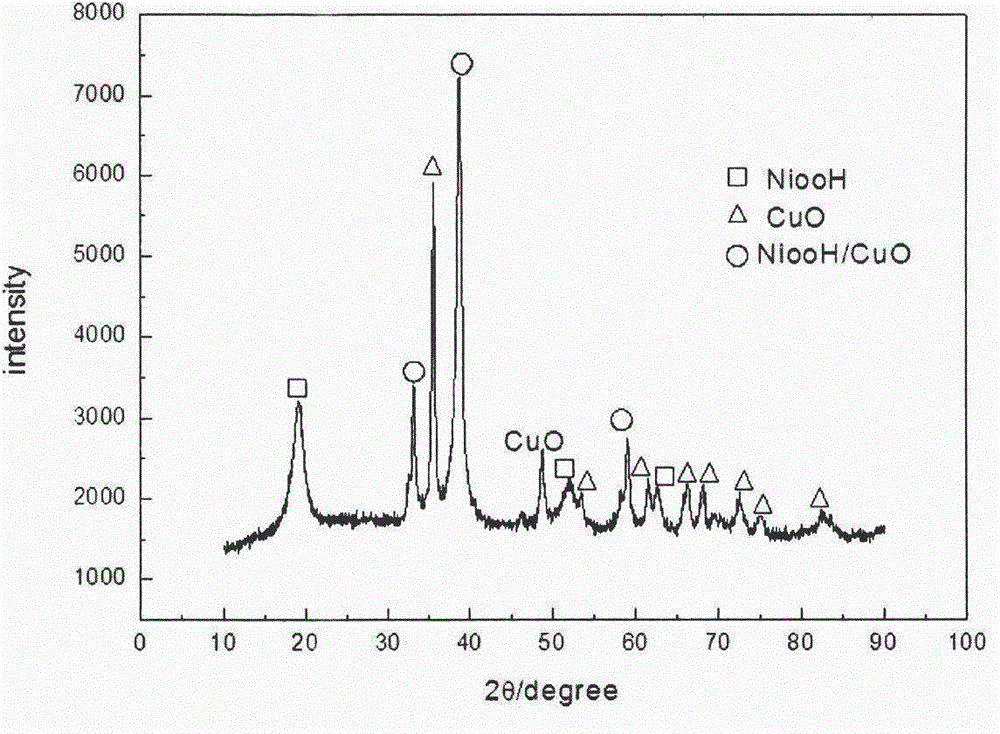

A kind of preparation method and application of copper-nickel composite oxide catalyst

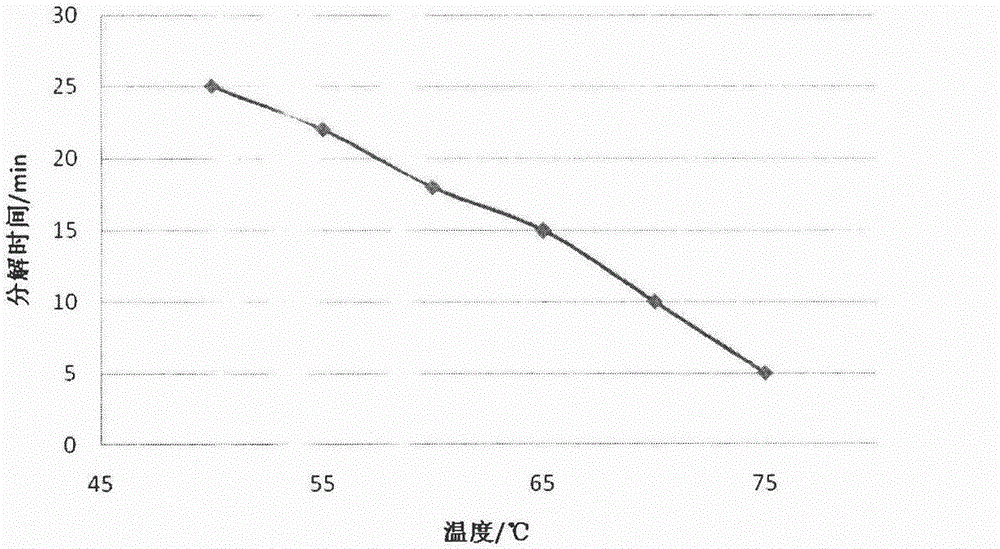

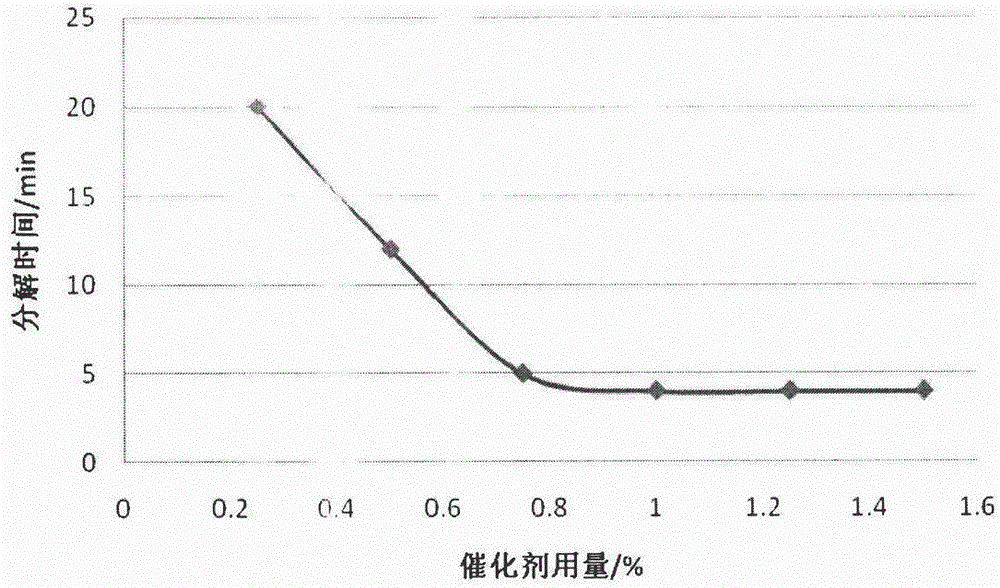

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, oxygen preparation, etc., can solve the problems of slow speed, high temperature and low efficiency for sodium hypochlorite decomposition problem, to achieve the effect of fast speed, overcome weak catalytic activity, and simple production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Weigh 2.91g (0.01mol) Ni(NO 3 ) 2 ·6H 2 O and 2.42g (0.01mol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100ml deionized water, weighed 1.8g (0.045mol) NaOH was dissolved in 100ml deionized water, and the NaOH solution was added to the Ni(NO 3 ) 3 with Cu(NO 3 ) 2 The mixed solution was stirred at room temperature for 8 hours to obtain a precursor solution.

[0024] (2) Add the precursor solution of step (1) into a 250ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 130°C for 10 hours, with a heating rate of 10°C / min.

[0025] (3) After the reaction of step (2) is completed, after the reaction solution is cooled naturally, the reaction solution is filtered, the product is washed with water, and after cleaning, the product obtained is dried in a drying oven at 100° C. for 8 hours to obtain a black product copper nickel composite oxide catalyst.

Embodiment 2

[0027] (1) Weigh 2.91g (0.01mol) Ni(NO 3 ) 2 ·6H 2 O and 2.42g (0.01mol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100ml deionized water, weighed 1.8g (0.045mol) NaOH was dissolved in 100ml deionized water, and the NaOH solution was added to the Ni(NO 3 ) 3 with Cu(NO 3 ) 2 The mixed solution was stirred at room temperature for 8 hours to obtain a precursor solution.

[0028] (2) Add the precursor solution of step (1) into a 250ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 120°C for 10 hours, with a heating rate of 10°C / min.

[0029] (3) After the reaction of step (2) is completed, after the reaction solution is cooled naturally, the reaction solution is filtered, the product is washed with water, and after cleaning, the product obtained is dried in a drying oven at 100° C. for 8 hours to obtain a black product copper nickel composite oxide catalyst.

Embodiment 3

[0031] (1) Weigh 2.91g (0.01mol) Ni(NO 3 ) 2 .6H 2 O and 2.42g (0.01mol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 100ml deionized water, weighed 1.8g (0.045mol) NaOH was dissolved in 100ml deionized water, and the NaOH solution was added to the Ni(NO 3 ) 3 with Cu(NO 3 ) 2 The mixed solution was stirred at room temperature for 8 hours to obtain a precursor solution.

[0032] (2) Add the precursor solution of step (1) into a 250ml hydrothermal reaction kettle, and conduct a hydrothermal reaction at 140°C for 10 hours, with a heating rate of 10°C / min.

[0033] (3) After the reaction of step (2) is completed, after the reaction solution is cooled naturally, the reaction solution is filtered, the product is washed with water, and after cleaning, the product obtained is dried in a drying oven at 100° C. for 8 hours to obtain a black product copper nickel composite oxide catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com