Solution polymerized butadiene-styrene random copolymer, preparation method thereof, and applications of composite conditioning agent

A technology of random copolymer and styrene, applied in the field of polymers, can solve the problems of affecting product performance, unsuitable vinyl products, difficult to control distribution, etc., to reduce the frequency of maintenance and cleaning, difficult to gel, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

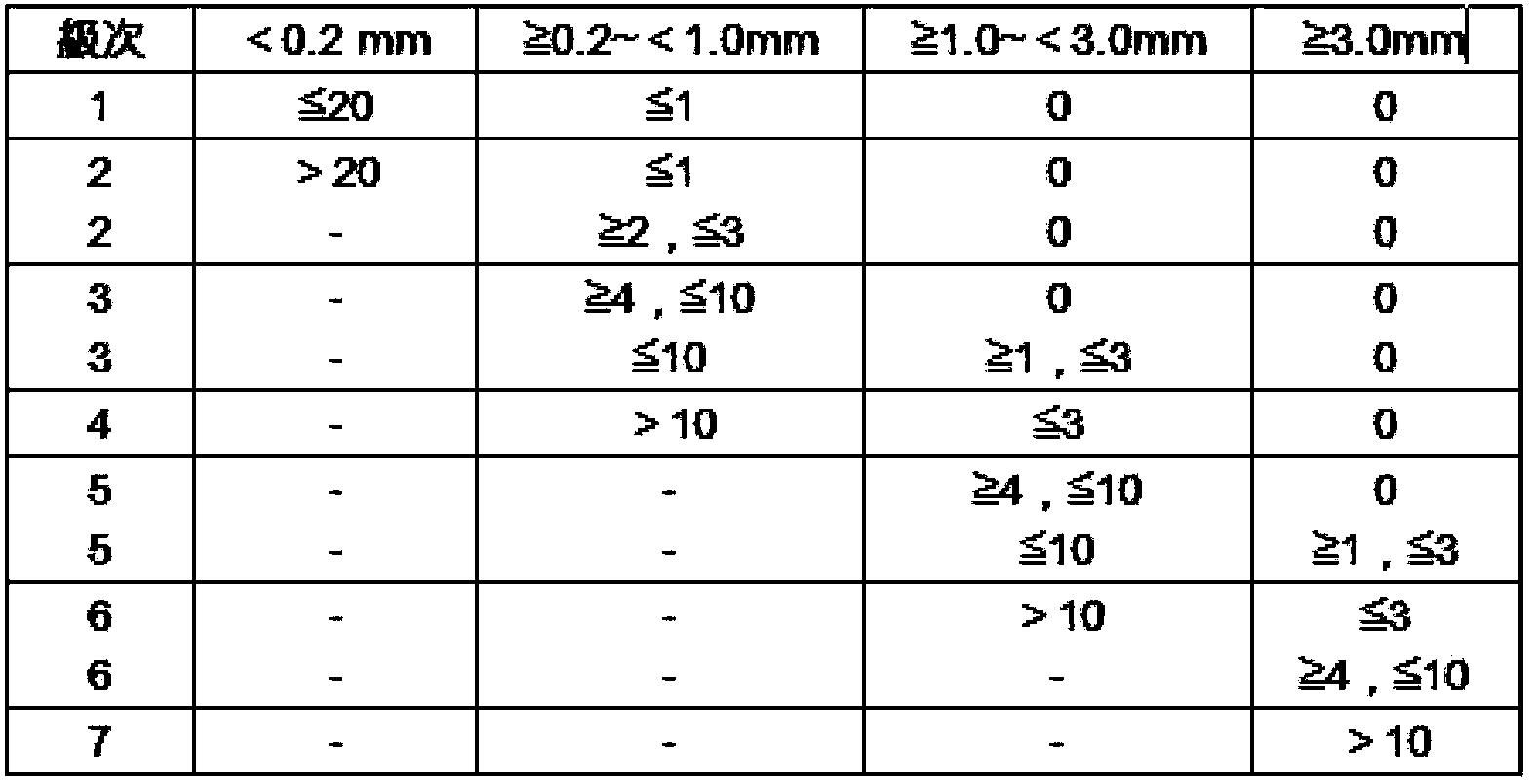

Image

Examples

Embodiment 1

[0025] The polymerization kettle was deoxidized by nitrogen replacement, 3000mL cyclohexane was metered and then injected into the polymerization kettle with nitrogen pressure, then 4.08g ethyl tetrahydrofurfuryl ether and 3.5g tetramethylethylenediamine were added, and 0.6mL (concentration 0.4mol / L) Butyllithium breaks impurities. After the temperature is raised to 50°C, 75g of styrene and 225g of butadiene are mixed uniformly in a premix tank, and 2mmol of initiator butyllithium (concentration 0.04mol / L) is prepared, and then mixed The monomer and the initiator are continuously added to the polymerization kettle at the same time, and the feeding time is 30 minutes. 0.5% antioxidant, condensed with water vapor, and dried to obtain a polymer. Using gel permeation chromatography (GPC), the molecular weight of the product was measured to be 142,060 g / mol, the molecular weight distribution was 1.31, and the Mooney viscosity was 35.2. The vinyl content by HNMR was 35.8%. The gel...

Embodiment 2

[0027] According to the mode of embodiment 1, just change the consumption of adjustment, 19.08g ethyl tetrahydrofurfuryl ether and 3.5g tetramethylethylenediamine, the product records vinyl content by HNMR and is 68.1%.

Embodiment 3

[0029] According to the method of Example 1, only the type of adjustment is changed, 4.08g of ethyl tetrahydrofurfuryl ether is 4.08g of isopropyl tetrahydrofurfuryl ether and 3.5g of tetramethylethylenediamine is N,N-dimethyl Tetrahydrofurfurylamine, the product records vinyl content by HNMR and is 38.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com