Compound conductive adhesive for electronic packaging and preparation method thereof

A composite conductive and electronic packaging technology, applied in the field of conductive adhesive, can solve the problems of low electrical conductivity and thermal conductivity, restricting high-power LED chips of silver-based conductive adhesives and high-end applications of large integrated circuits, etc., to improve thermal conductivity and The effect of electrical conductivity and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

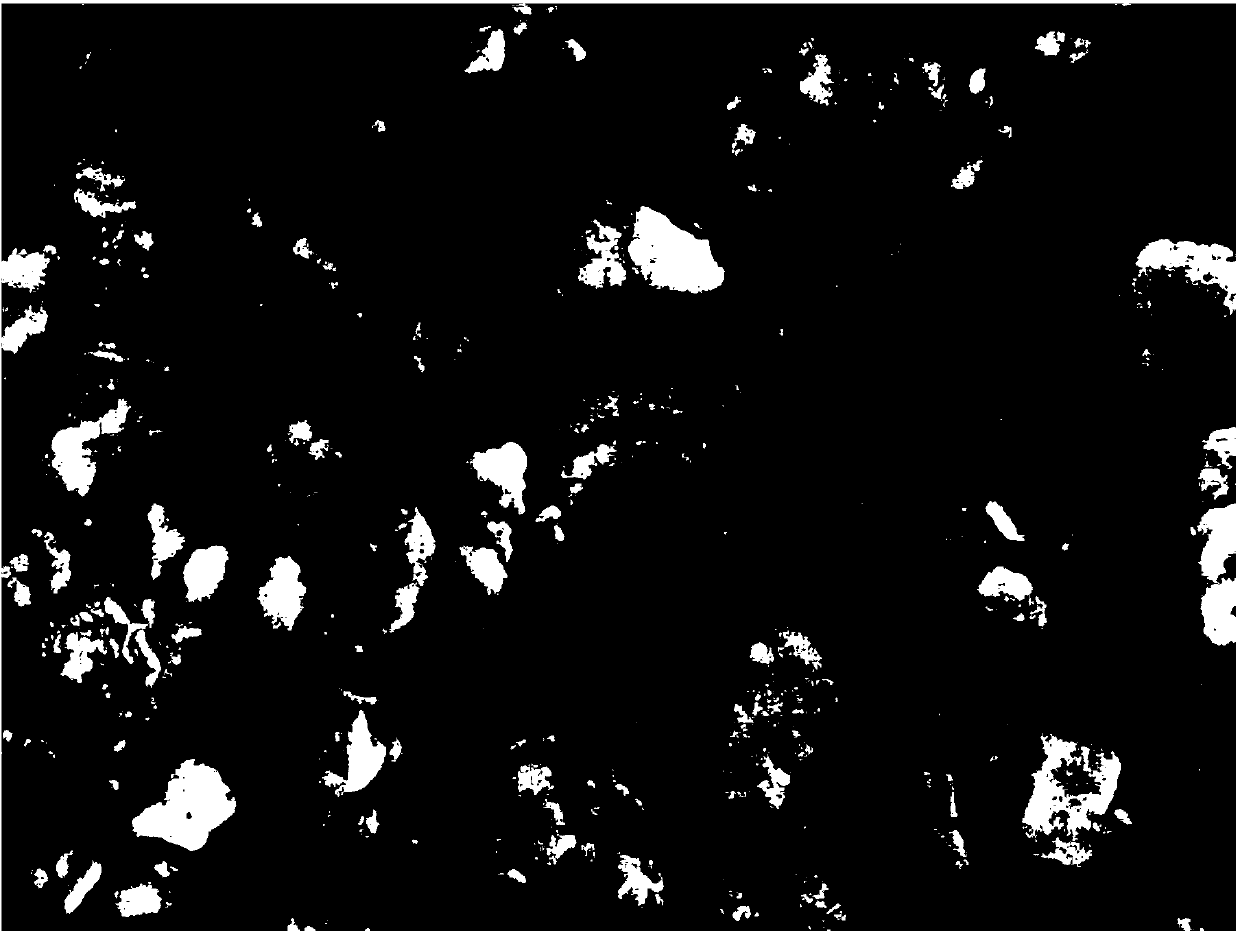

Image

Examples

Embodiment 1

[0030] Step 1): Activation treatment of carbon nanotubes

[0031] (1) The carbon nanotubes were added into the mixed acid solution, and ultrasonically treated for 60 min to obtain the suspension mixture. Heat the mixture to reflux in a water bath at 60°C for 5 hours, then dilute with deionized water, filter under reduced pressure, and wash until neutral to obtain separated carbon nanotubes. Put the obtained separated carbon nanotubes into a watch glass placed in an oven at 60°C for 24 hours to obtain acidified carbon nanotubes, the mixed acid solution is composed of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% and potassium permanganate according to the mass ratio 3:0.85:0.15, the amount of carbon nanotubes added is 1g per 100mL of mixed acid solution.

[0032] (2) The acidified carbon nanotubes were added to the activation solution, ultrasonically treated for 30 min, and placed in a water bath at 40° C. for 2...

Embodiment 2

[0037] Step 1): Activation treatment of carbon nanotubes

[0038] (1) The carbon nanotubes were added into the mixed acid solution, and ultrasonically treated for 60 min to obtain the suspension mixture. Heat the mixture to reflux in a water bath at 60°C for 5 hours, then dilute with deionized water, filter under reduced pressure, and wash until neutral to obtain separated carbon nanotubes. Put the obtained separated carbon nanotubes into a watch glass placed in an oven at 60°C for 24 hours to obtain acidified carbon nanotubes, the mixed acid solution is composed of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% and potassium permanganate according to the mass ratio 3:0.85:0.15, the amount of carbon nanotubes added is 1.25g per 100mL mixed acid solution.

[0039] (2) The acidified carbon nanotubes were added to the activation solution, ultrasonically treated for 30 min, and placed in a water bath at 40° C. for 2...

Embodiment 3

[0044] Step 1): Activation treatment of carbon nanotubes

[0045] (1) The carbon nanotubes were added into the mixed acid solution, and ultrasonically treated for 60 min to obtain the suspension mixture. Heat the mixture to reflux in a water bath at 60°C for 5 hours, then dilute with deionized water, filter under reduced pressure, and wash until neutral to obtain separated carbon nanotubes. Put the obtained separated carbon nanotubes into a watch glass placed in an oven at 60°C for 24 hours to obtain acidified carbon nanotubes, the mixed acid solution is composed of concentrated sulfuric acid with a mass fraction of 98% and concentrated nitric acid with a mass fraction of 65% and potassium permanganate according to the mass ratio 3:0.85:0.15, the amount of carbon nanotubes added is 1.3g per 100mL mixed acid solution.

[0046] (2) The acidified carbon nanotubes were added to the activation solution, ultrasonically treated for 30 min, and placed in a water bath at 40° C. for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com