Sodium alkylphenol polyoxyethylene ether acetate ternary-compounded descaling agent

A technology of alkylphenol polyoxyethylene ether sodium acetate, descaling agent, applied in detergent compositions, surface active detergent compositions, chemical instruments and methods, etc., can solve the problem of poor water solubility and hard water resistance, skin Problems such as high irritation and application limitations, to achieve the effects of low synthesis cost, simple synthesis steps, and good descaling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

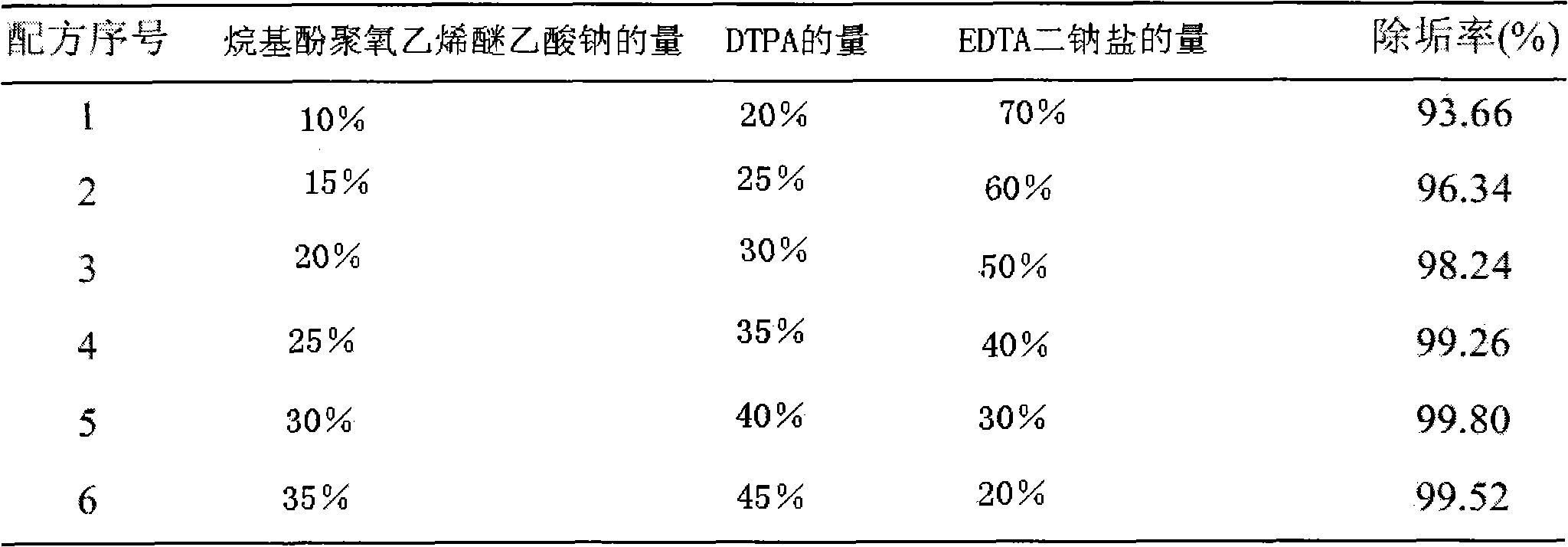

[0014] The invention relates to a ternary compound descaling agent of alkylphenol polyoxyethylene ether sodium acetate, which is prepared by mixing and compounding alkylphenol polyoxyethylene ether sodium acetate, DTPA and EDTA disodium salt, and according to the mass percentage In total, the alkylphenol polyoxyethylene ether sodium acetate accounts for 10% to 30% of the total amount, the DTPA accounts for 20% to 40% of the total amount, and the balance is EDTA disodium salt.

[0015] In terms of mass percentage, the alkylphenol polyoxyethylene ether sodium acetate accounts for 15% of the total amount, the DTPA accounts for 25% of the total amount, and the balance is EDTA disodium salt.

[0016] In terms of mass percentage, the alkylphenol polyoxyethylene ether sodium acetate accounts for 30% of the total amount, the DTPA accounts for 40% of the total amount, and the balance is EDTA disodium salt.

[0017] In terms of mass percentage, the alkylphenol polyoxyethylene ether sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com