A method for pollution prevention and vegetation restoration of metal sulfide ore solid waste storage yard

A technology for sulfide ore and storage yards, applied in botany equipment and methods, excavation, gardening, etc., can solve problems such as unsatisfactory effects and comprehensive utilization of tailings less than 10%, achieve a good ecological environment, and reduce toxic and heavy metals The effect of releasing and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Dexing City, Jiangxi Province, Jiangxi Copper Co., Ltd. Dexing Copper Mine Shuilongshan waste rock yard A test area, the slope surface is relatively loose, and the waste rock contains sulfide minerals, and there is no soil layer; the pH value of the waste rock is 3.0 Left and right, the acidity is high, which seriously restricts the normal growth of plants.

[0053] Follow the steps in order:

[0054] 1) Prepare the acidic improvement layer: Mix the loam, lime and binder evenly, among which the loam and lime are mixed according to the volume ratio of 15:1, and the binder is calculated based on the unit area to be sprayed, and the specific dosage For adhesive 10g / m 2 .

[0055] 2) Preparation of substrate layer: uniformly mix the greening substrate, loam, water-retaining agent and adhesive, wherein the greening substrate and loam are mixed according to the volume ratio of 2:8, and the water-retaining agent and adhesive are to be sprayed The unit area of sowing is ca...

Embodiment 2

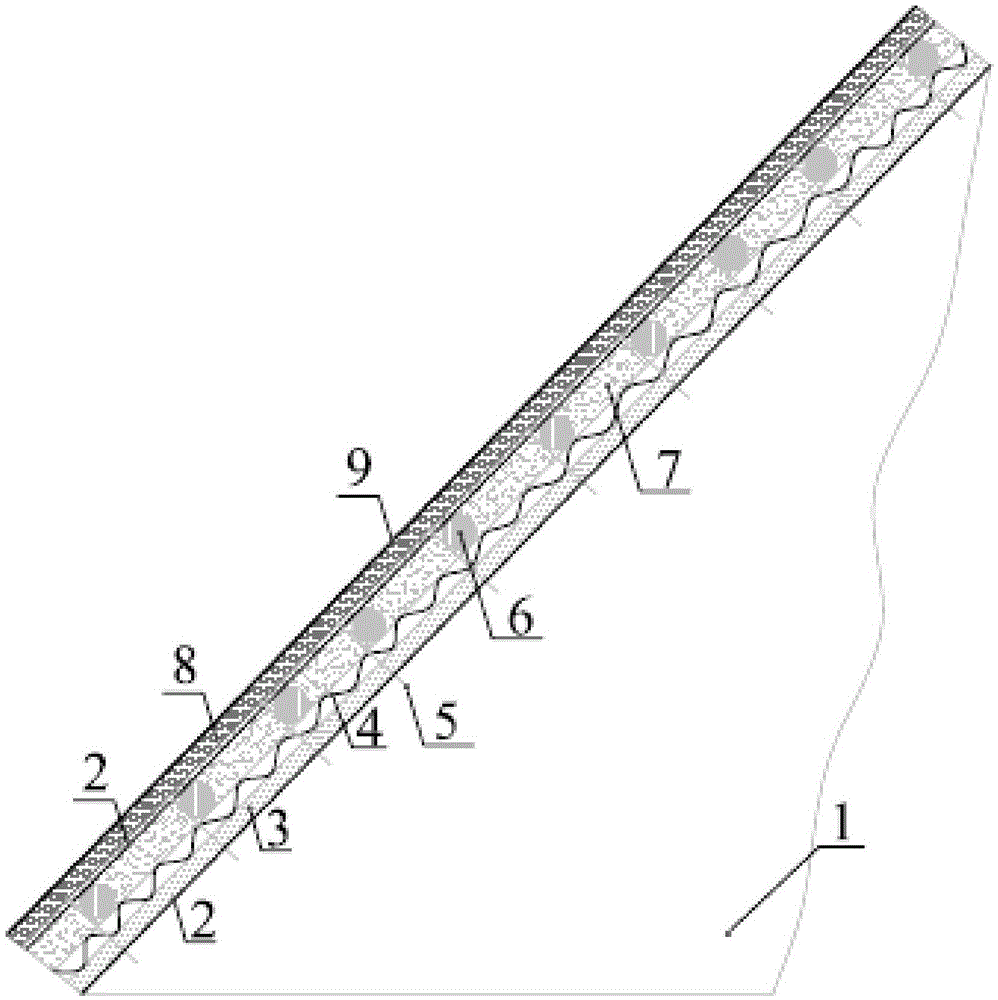

[0071] Dexing City, Jiangxi Province, Jiangxi Copper Co., Ltd. Dexing Copper Mine Shuilongshan waste rock yard A test area, the slope surface is relatively loose, and the waste rock contains sulfide minerals, and there is no soil layer; the pH value of the waste rock is 3.0 Left and right, the acidity is high, which seriously restricts the normal growth of plants. Follow the steps below in sequence (combining figure 1 Schematic diagram of the slope structure shown):

[0072] 1) Prepare the acidic improvement layer: Mix the loam, lime and binder evenly, among which the loam and lime are mixed according to the volume ratio of 20:1, and the binder is calculated according to the unit area to be sprayed, and the specific dosage 15g / m for adhesive 2 .

[0073] 2) Preparation of substrate layer: uniformly mix the greening substrate, loam, water-retaining agent and adhesive, wherein the greening substrate and loam are mixed according to the volume ratio of 3:7, and the water-retain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com