Eddy-current opposite-impacting type gas mixer arranged in gas passage

A gas mixer and gas channel technology, used in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of increased system pressure drop, increased power consumption of induced draft fans, etc., to reduce ammonia escape rate, The effect of prolonging the mixing distance and improving the denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

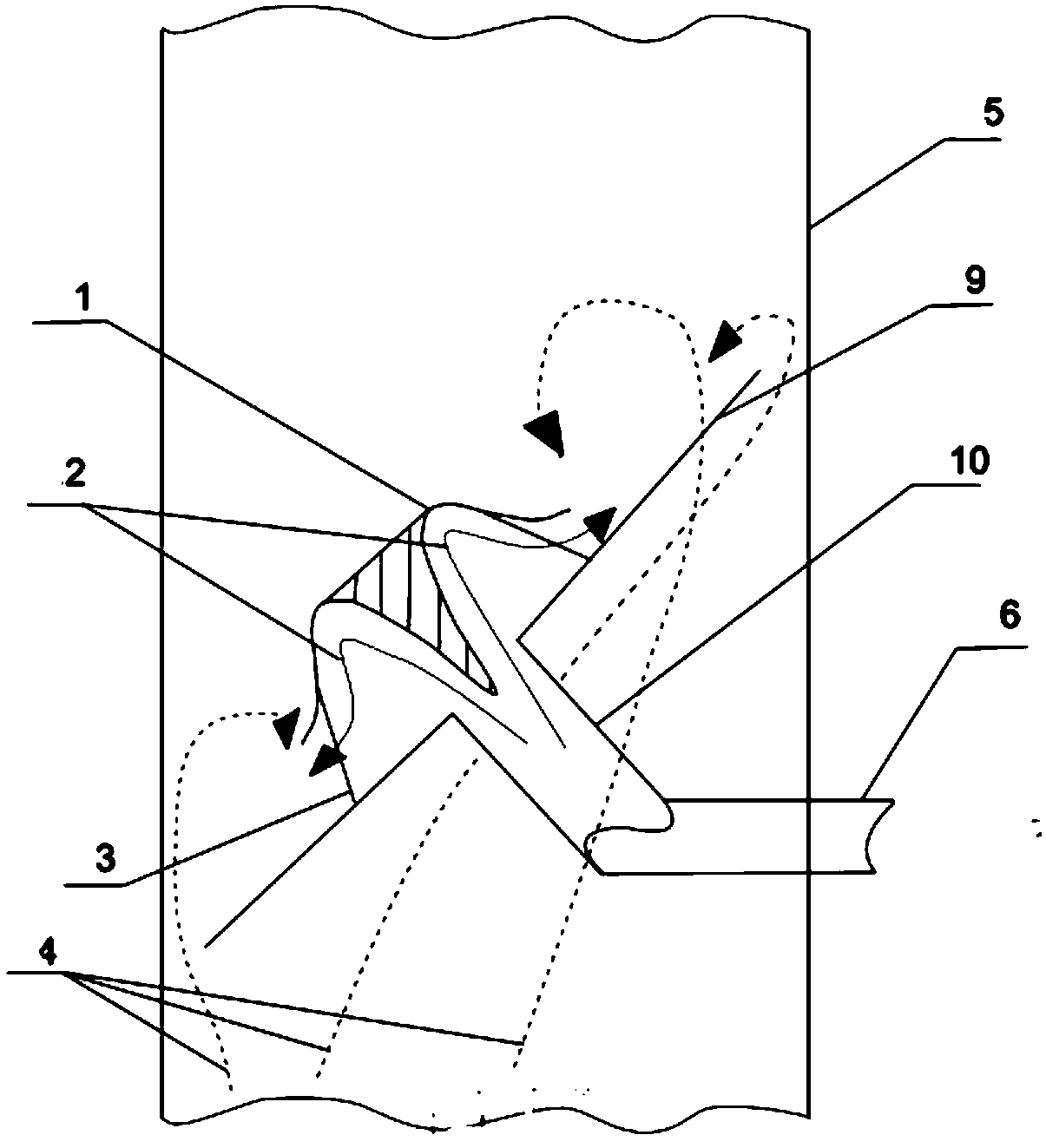

[0016] The embodiment of the present invention aims at uniformly mixing the ammonia gas denitrified by the selective catalytic reduction method and the waste gas of the power plant passing through the gas mixer in the existing thermal power plant units. However, the application occasions of the gas mixer of the present invention and the gas mixing device composed thereof are not limited thereto, and can be applied to applicable occasions requiring gas mixing that can be imagined by those of ordinary skill in the art. At this time, the gas channel is the flue in the thermal power plant, and the flue wall 5 is as figure 1 shown.

[0017] The vortex counter-type gas mixer arranged in the gas channel in this embodiment is set as figure 1 As shown, it includes a flow guide device 1, a nozzle 10, a pipe 6, a flue gas turbulence device 9, and a support device 3; the pipe 6 penetrates the side wall of the flue and continues to extend; the nozzle 10 is arranged on the pipe 6 to extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com