A kind of metal oxide/tio2 nanometer catalyst and preparation method thereof

A nano-catalyst and oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., to achieve the effect of simple equipment, stable structure and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

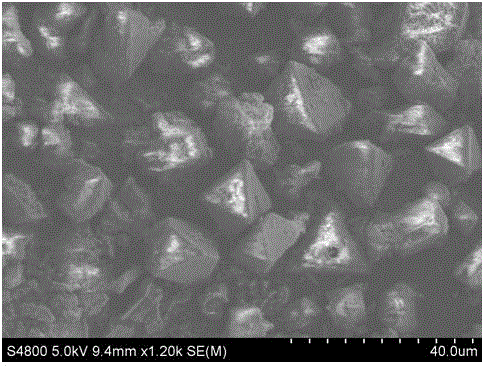

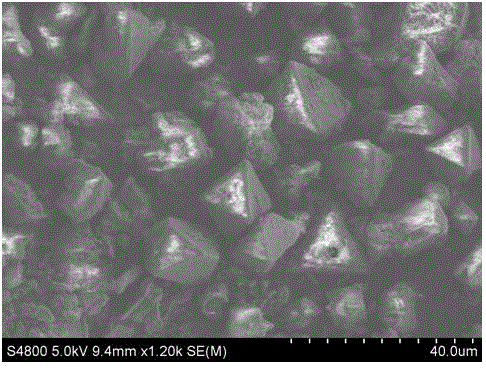

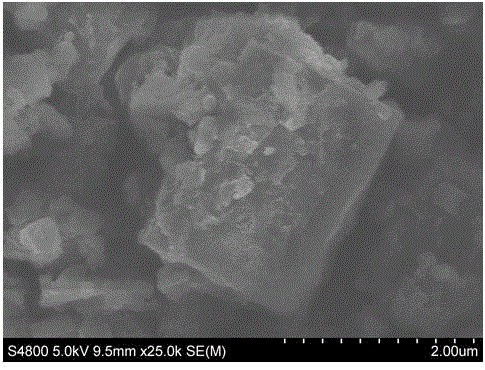

Image

Examples

Embodiment 1

[0034] Metal-organic compound copper trimesate (CuBTC) was used as template and titanium isopropoxide was used as titanium source to prepare metal oxide / TiO with complementary structure of metal-organic compound 2 nanocatalysts.

[0035] (1) Synthesis of template: Mix copper nitrate trihydrate aqueous solution with trimesic acid / ethanol solution (volume ratio 1:1) and transfer to a hydrothermal kettle for 10 hours at 80°C; dissolve the product obtained above in two In the methyl chloride solvent, after centrifugation at room temperature for 3 times, the metal organic compound precipitated from the lower layer was dried at 100°C for 12 hours, the centrifugation process was selected at a speed of 4000 rpm, and the centrifugation time was 2 minutes;

[0036](2) Introduce titanium source: heat the above product to 140°C under vacuum and keep it for 18 hours. After cooling down to room temperature, add 10ml of titanium isopropoxide to 2g of the product, and continue vacuuming to ma...

Embodiment 2

[0041] Preparation of Metal Oxide / TiO with Complementary Metal-Organic Compound Structure Using Metal-organic Copper Tricarboxylate (FeBDC) as Template and Titanium Isopropoxide as Titanium Source 2 nanocatalysts.

[0042] (1) Synthesis of templates: Mix ferric chloride hexahydrate aqueous solution with terephthalic acid / N,N-dimethylformamide solution (volume 15mL) and transfer to a hydrothermal kettle for 7 hours at 120°C; The product obtained above was soaked in ethanol at 60°C for 3 hours, centrifuged for 3 times, and the metal organic compound precipitated from the lower layer was dried at 60°C for 24 hours. During the centrifugation process, the rotation speed was 4500 rpm, and the centrifugation time was 1 minute;

[0043] (2) Introduction of titanium source: heat the above product to 250°C under vacuum, and keep it for 12 hours. After cooling down to room temperature, add 4ml of titanium isopropoxide to 600mg of the product, and continue vacuuming, maintaining a dynamic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com