Producing method of yellowing-resistant general anatase titanium dioxide

An anatase type titanium dioxide and anatase type technology are applied in chemical instruments and methods, inorganic pigment processing, dyeing organosilicon compound processing and other directions, which can solve the problems of not involving the improvement of product anti-yellowing, not involving anti-yellowing and other problems. , to achieve the effect of strong water dispersion stability, good lattice stability and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

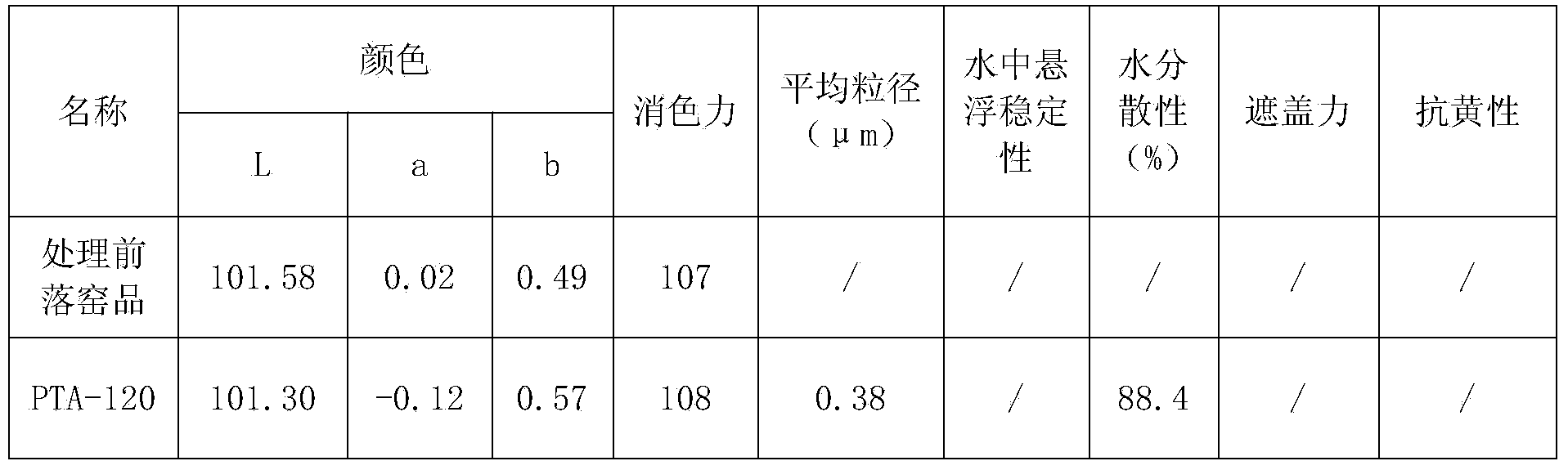

[0045] Embodiment one is prepared by the method of the present invention

[0046] The primary product obtained by the rotary kiln is made into a slurry of 850g / l with desalinated water, and sodium silicate is used as a wetting agent. Adjust the pH value to 10.00 with NaOH, disperse and sand-mill (the residue on a 325-mesh sieve is less than 0.01%); dilute the titanium dioxide slurry obtained after sand-milling to a concentration of 310g / l, and adjust the pH value with 200g / l NaOH 10.00, heat up to 60°C, add 0.6% titanium dioxide mass sodium silicate solution (as SiO 2 Calculated), aging for 60min after the end; add aluminum sulfate 0.7% (as Al 2 o 3 Calculated), aging for 25 minutes after the end; at 50 minutes, add sodium metaaluminate 0.85% (Al 2 0 3 After the completion of aging for 45 minutes, aluminum sulfate was added to adjust the pH of the slurry to 8.0, and aging for 1 hour.

[0047] Filter the obtained titanium dioxide slurry, wash for 2 hours, flash dry to make...

Embodiment 2

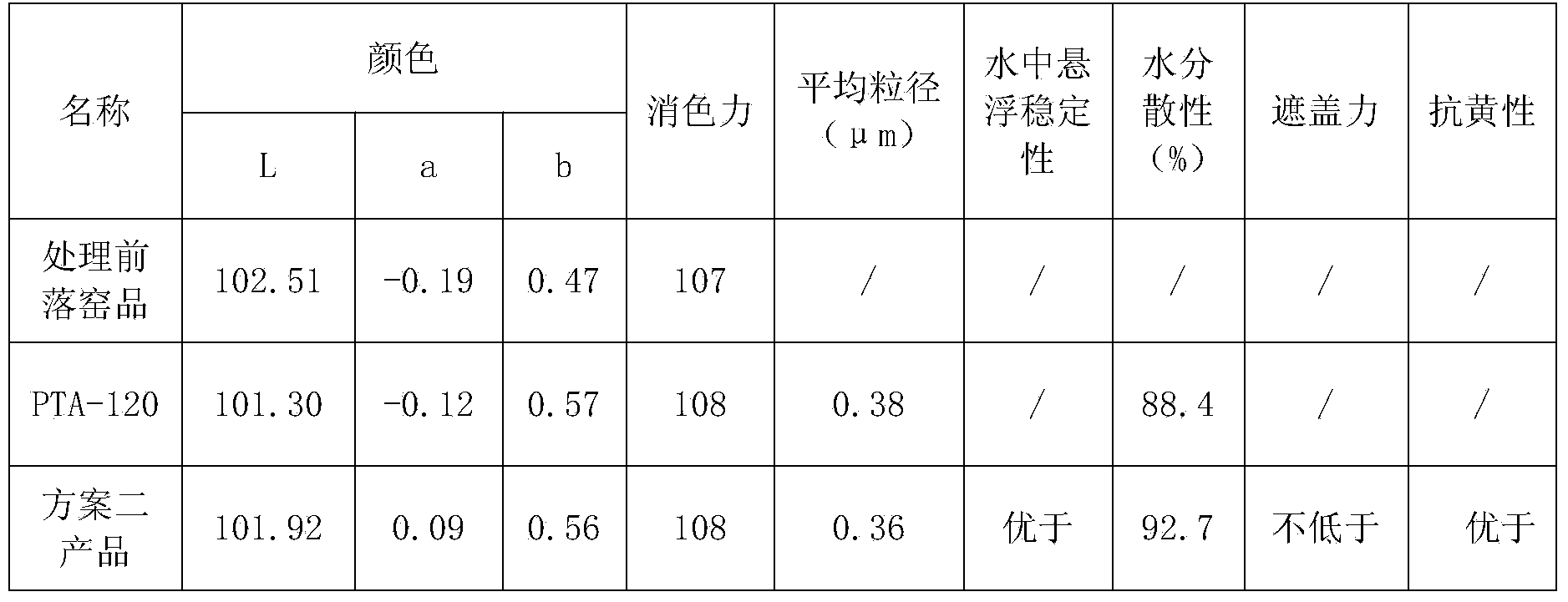

[0074] Embodiment two is prepared by the method of the present invention

[0075] The primary product obtained by the rotary kiln is made into 850g / l slurry with desalinated water, isopropanolamine is used as a wetting agent, and the pH value is adjusted to 10.00 with 200g / l NaOH, and then dispersed and sand-milled (325 mesh sieve) The residue is less than 0.01%); dilute the titanium dioxide slurry obtained after sand grinding to a concentration of 310g / l, adjust the pH value to 10.00 with 200g / l NaOH, raise the temperature to 60°C, and add silicon dioxide with a mass of 0.8% of titanium dioxide in 10 minutes Sodium acid solution (as SiO 2 Calculated), aging for 60min after the end; add aluminum sulfate 0.7% (as Al 2 o 3 Calculated), aging for 25 minutes after the end; at 50 minutes, add sodium metaaluminate 0.85% (Al 2 0 3 After the completion of aging for 45 minutes, aluminum sulfate was added to adjust the pH of the slurry to 8.0, and aging for 1 hour.

[0076] Filter ...

Embodiment 3

[0081] Embodiment three is prepared by the method of the present invention

[0082] The primary product obtained by the rotary kiln is made into a slurry of 850g / l with desalinated water, and sodium hexametaphosphate is used as a wetting agent, and the addition amount of sodium hexametaphosphate is based on P 2 o 5 Calculated as 0.2% of the titanium dioxide mass in the titanium dioxide slurry, adjust the pH value to 10.00 with 200g / l NaOH, disperse and sand mill (325 mesh sieve residue is less than 0.01%); dilute the titanium dioxide slurry obtained after sand grinding to The concentration is 310g / l, use 200g / l NaOH to adjust the pH value to 10.00, raise the temperature to 60°C, add a sodium silicate solution with 0.8% titanium dioxide mass (as SiO 2 Calculated), aging for 60 minutes after the end; add 0.85% aluminum sulfate (as Al 2 o 3 Add 1.15% sodium metaaluminate (calculated as Al2O3) within 50 minutes, and mature for 45 minutes after the completion of the curing. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com